A 1:2 extremely low liquor ratio yarn dyeing machine

A yarn dyeing machine and liquor ratio technology, applied in the field of dyeing and finishing machinery, can solve the problems of increased dye discharge, low dye concentration, etc., and achieve the effects of excellent energy efficiency, obvious economic and social benefits, and short flow channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the implementation and protection of the present invention are not limited thereto. If there are no specific details below, those skilled in the art can refer to the prior art.

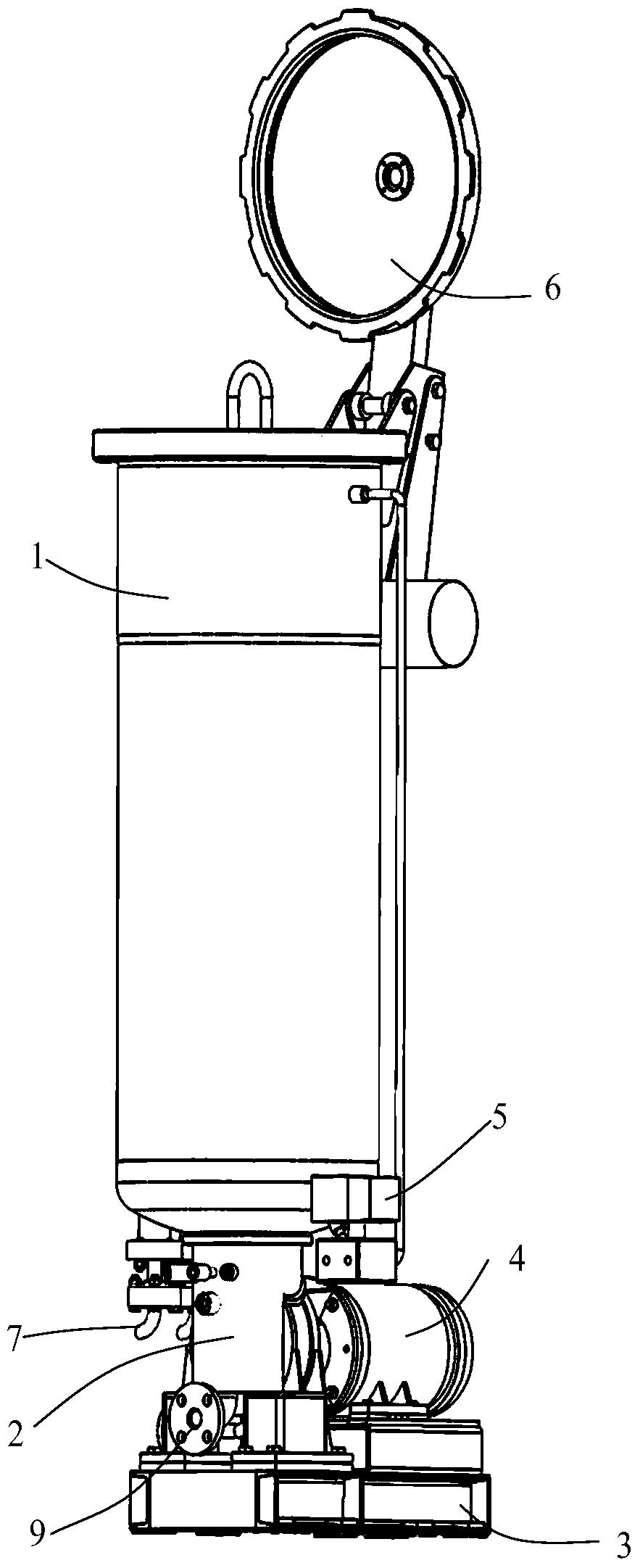

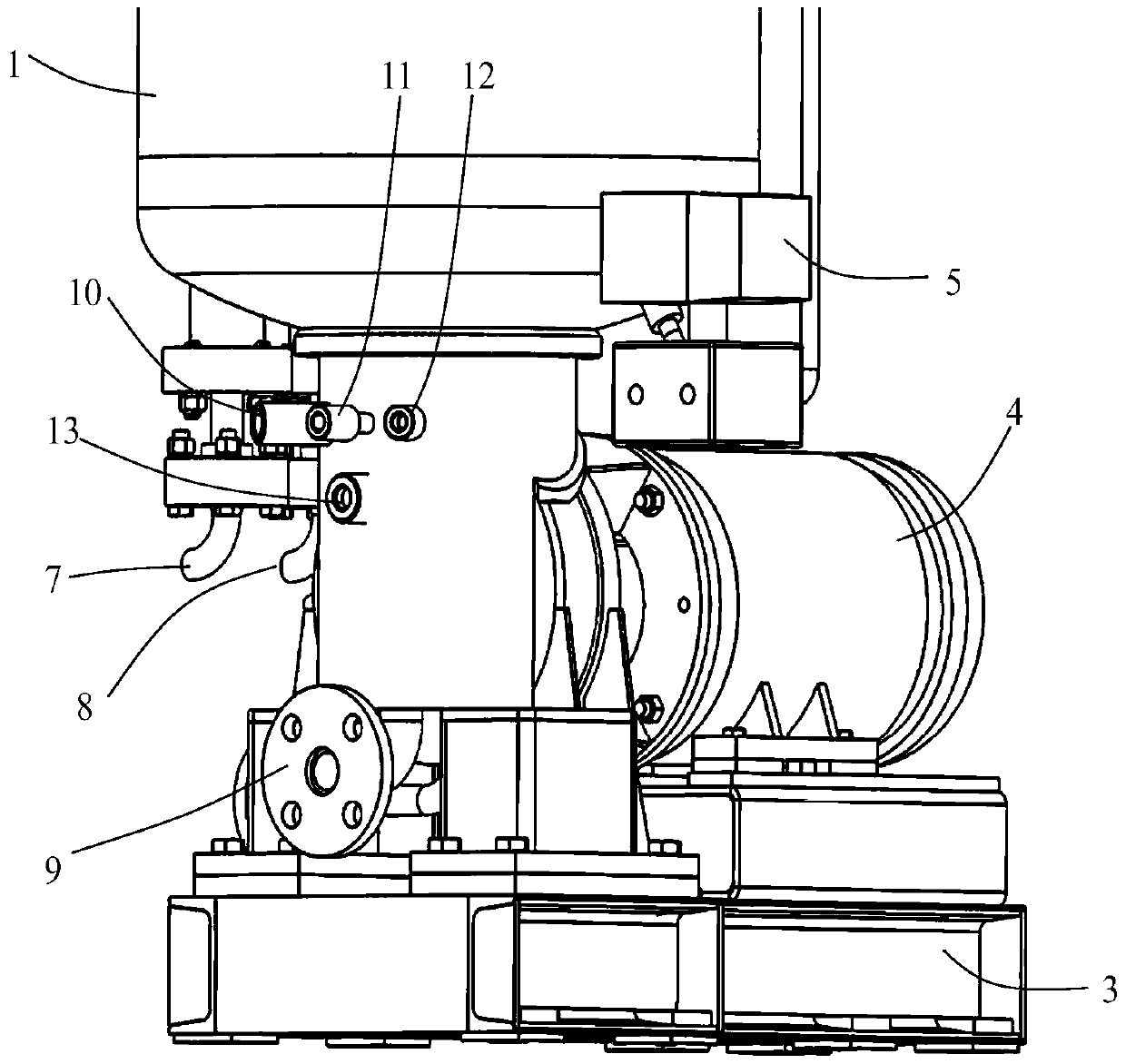

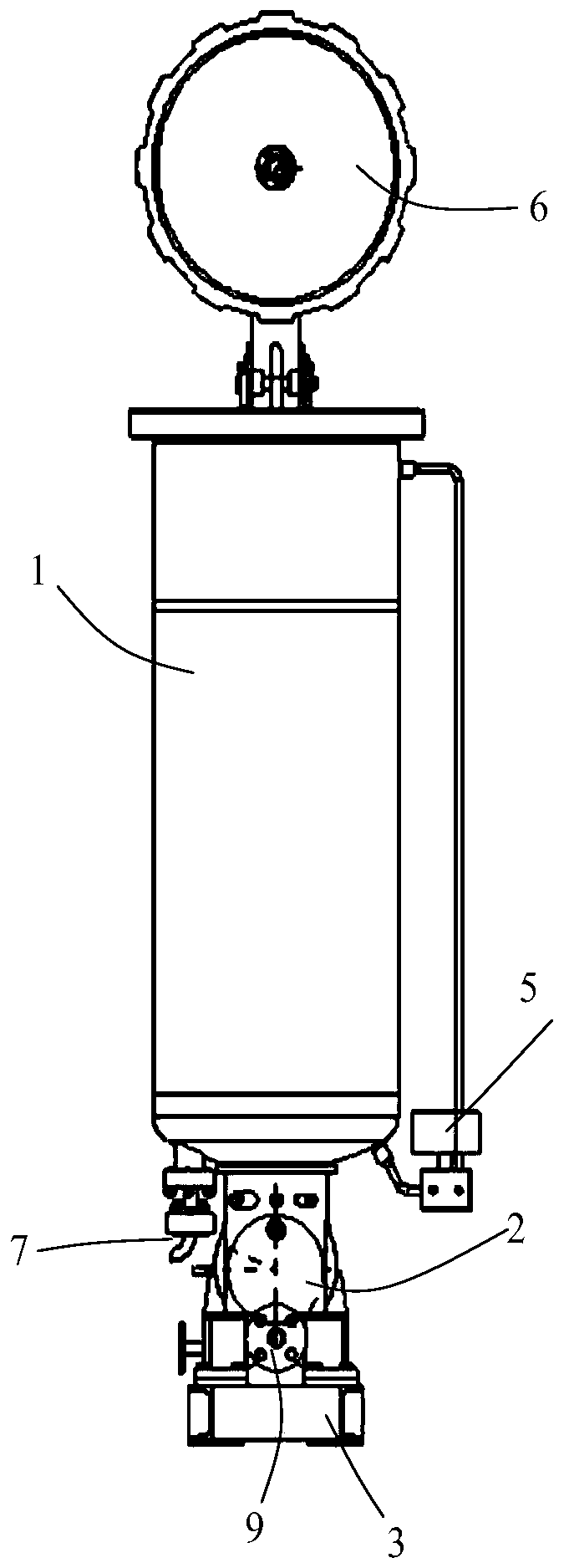

[0036] Such as Figure 1 ~ Figure 4 As shown, a yarn dyeing machine with a very low bath ratio of 1:2 includes a yarn cylinder 1, a liquid collecting pipe 2, a base 3, a motor 4, a volume meter 5, a cylinder head 6, a steam inlet 7, and a steam outlet 8, Liquid supply and discharge pipe 9, liquid temperature gauge 10, high-pressure pressure gauge 11, low-pressure pressure gauge 12, distribution plate 15, sky-round local pipe 16, gauze bamboo tube 17, liquid collection chamber 18, mixed-flow pump 19, diversion pipe 20 and water baffle 21;

[0037]Wherein the guide tube 20 is composed of two side plates and an annular guide plate, and the two side plates of the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com