Soft washing dual-purpose machine

A soft and water-washable technology, which is applied to textile processing machine accessories, liquid/gas/steam removal with squeeze rollers, textiles and papermaking, etc., can solve the problem of increased difficulty in processing fine-denier polyester filaments The labor intensity of dehydration is high, and the softening requirements cannot be met, so as to achieve better softening effect, realize cleaner production, and reduce the use of centrifugal dehydration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments.

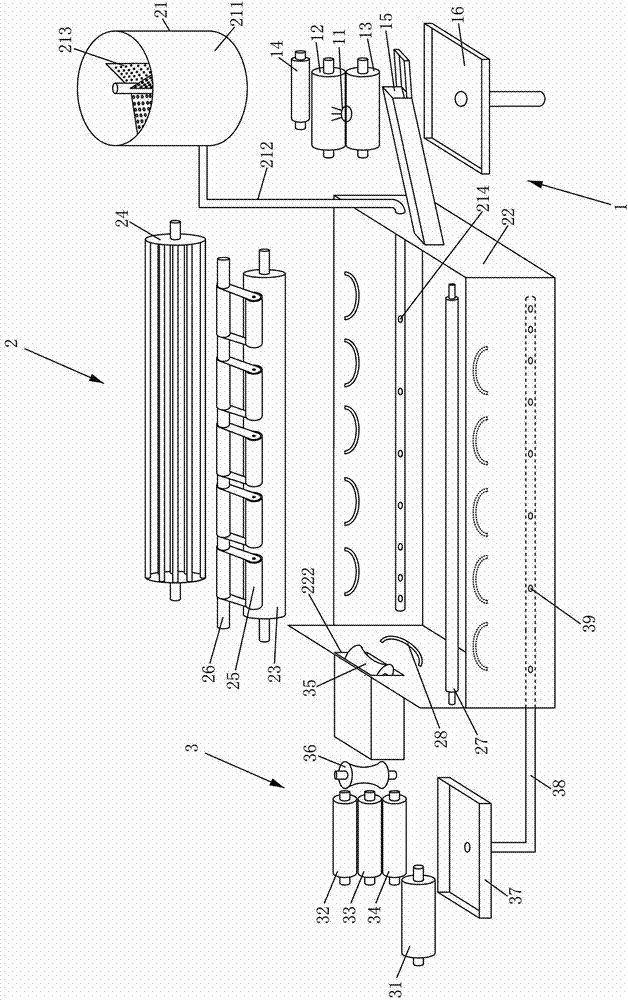

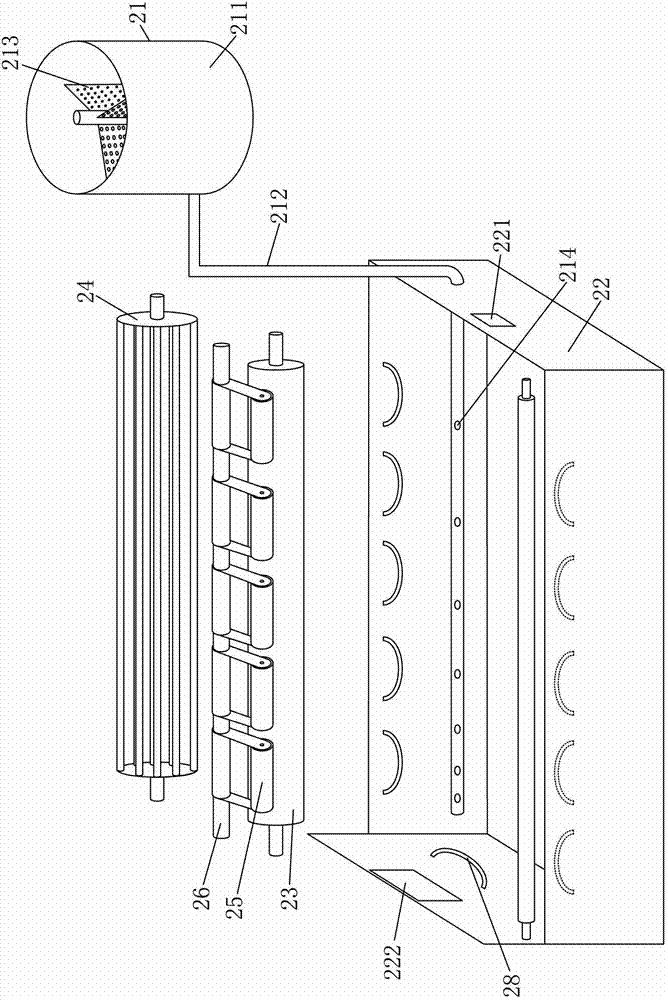

[0025] Such as figure 1 , figure 2 The soft washing machine shown includes a cloth feeding mechanism 1, a soft washing mechanism 2 and a cloth outlet mechanism 3, and the soft washing mechanism 2 includes a liquid adding device 21, a soft tank 22, a first cloth guide roller 23 and an octagonal roller 24 , the first cloth guide roller 23 and the octagonal roller 24 are arranged on the top of the soft groove 22 parallel to each other. Five self-weight rollers 25, five self-weight rollers 25 are arranged side by side at intervals and can swing up and down on a support shaft 26, and the front part of the first cloth guide roller 23 is provided with a support parallel to the first cloth guide roller 23. Cloth roller 27, on the side wall of flexible groove 22, be provided with some cloth guide rings 28, be respectively provided with five semicircular cloth guide rings 28 on the front side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com