Full biodegrade mulch master batch as well as preparation method and application thereof

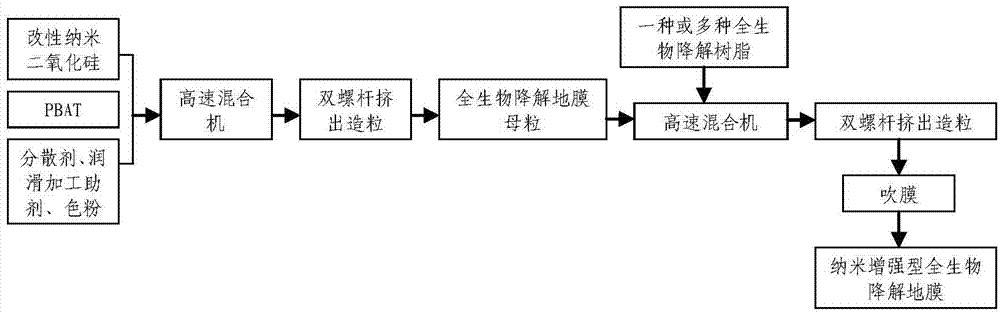

A degradable mulch film and all-biological technology, applied in the field of plastic masterbatch manufacturing, to achieve the effect of improving mechanical properties, increasing compatibility, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Implementation example 1 The fully biodegradable mulch film transparent masterbatch produced by the present invention

[0027] The masterbatch of the present embodiment is made up of following weight percentage composition:

[0028] PBAT 63%,

[0029] Modified Nano Silica 30%,

[0030] EBS 4%,

[0031] Liquid paraffin 3%,

[0032] Preparation process: Mix in a high-speed mixer for 30 minutes at a speed of 700-1000r / min; put the mixture in a twin-screw extruder with a length-to-diameter ratio of 1:48 and granulate to obtain a transparent fully biodegradable film masterbatch.

Embodiment 2

[0033] Implementation example 2 The fully biodegradable mulch film transparent masterbatch produced by the present invention

[0034] PBAT 75%,

[0035] Modified Nano Silica 15%,

[0036] Erucamide 5%,

[0037] Liquid paraffin 5%,

[0038] The preparation process is the same as the preparation method described in Example 1.

Embodiment 3

[0039] Implementation example 3 The black masterbatch of fully biodegradable plastic film of the present invention

[0040] PBAT 75%,

[0041] Modified Nano Silica 10%,

[0042] EBS 5%,

[0044] Carbon black 5%

[0045] The preparation process is the same as the preparation method described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com