Nano silver conductive coating

A conductive coating and nano-silver technology, applied in the field of water-soluble nano-silver conductive coatings and oil-soluble nano-silver conductive coatings, can solve the problem of unsatisfactory conductivity and stability of conductive polymers, poor conductivity of carbon nanotubes, and silver grids. The etching process is complex and other problems, so as to achieve the effects of low manufacturing cost, no pollution in reaction conditions, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

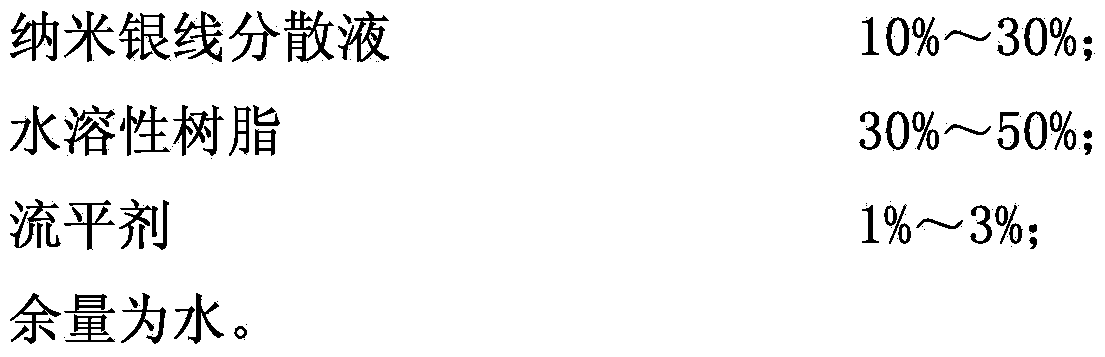

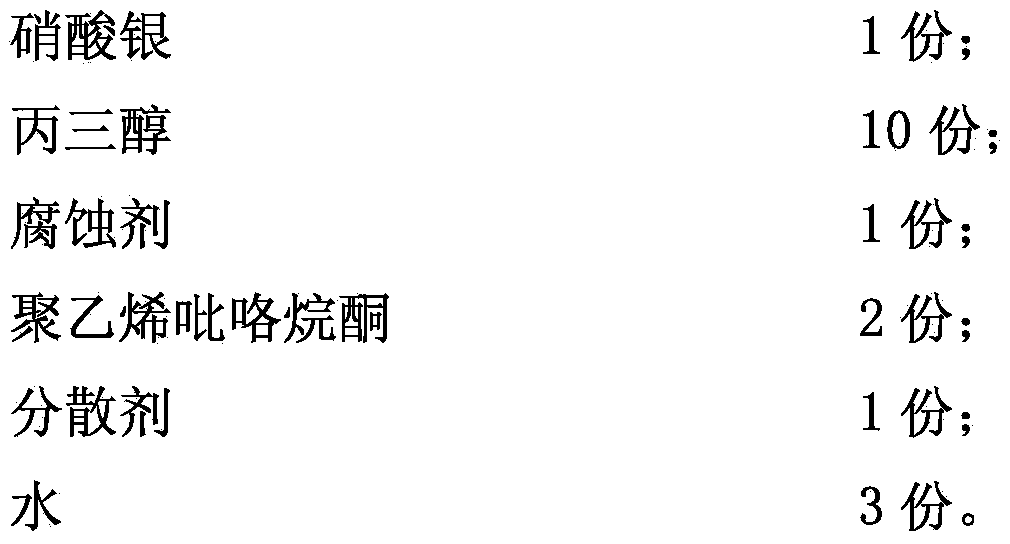

[0029] The preparation method of the silver nano wire dispersion liquid is as follows: stirring and reacting the above-mentioned materials in various parts by weight at 200° C. for 20-30 minutes.

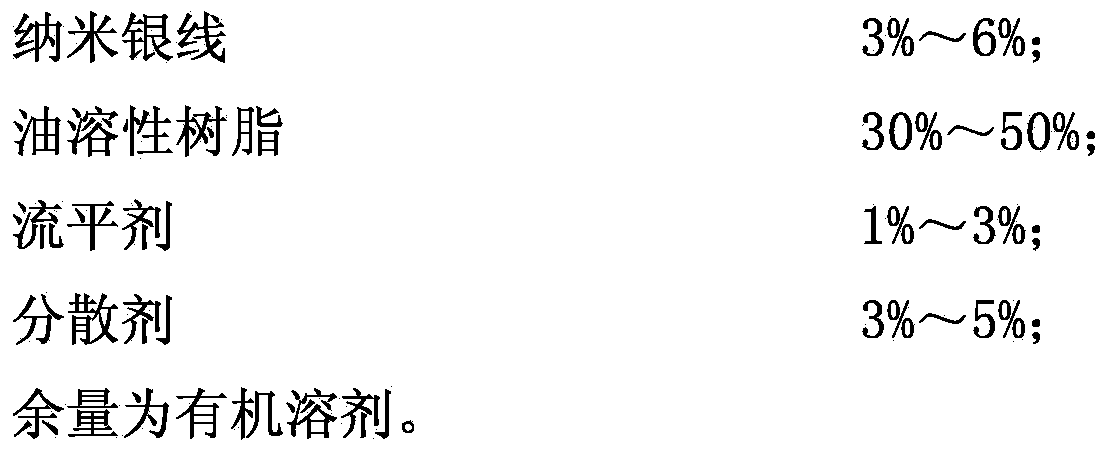

[0030] Among them, glycerol is a reducing agent, and the corrosive agent is ammonium chloride or ammonium fluoride. The corrosive agent decomposes at high temperature to generate ammonia gas, hydrogen chloride or hydrogen fluoride, ammonia gas escapes, and hydrogen chloride and hydrogen fluoride play the role of etching nano silver wires. Polyvinylpyrrolidone is a surfactant, and the dispersant can preferably be selected from acetylacetone, hexaphosphine, ethylenediaminetetraacetic acid or combinations thereof. The leveling agent is selected from polydimethyl silicone oil, polyether modified organosiloxane or a combination thereof.

[0031] Coat the water-soluble nano-silver conductive paint on the optical PET, adjust the coating thickness to 0.5-0.8 microns, and dry it at 120°C. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com