Full-automatic sand casting molding machine for clay sand

A sand casting, fully automatic technology, applied in the field of sand casting, can solve the problems of low compactness of sand molding, difficult transportation, frequent shutdown and cleaning, etc., to achieve the effect of ensuring sand molding effect, improving safety and stability, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

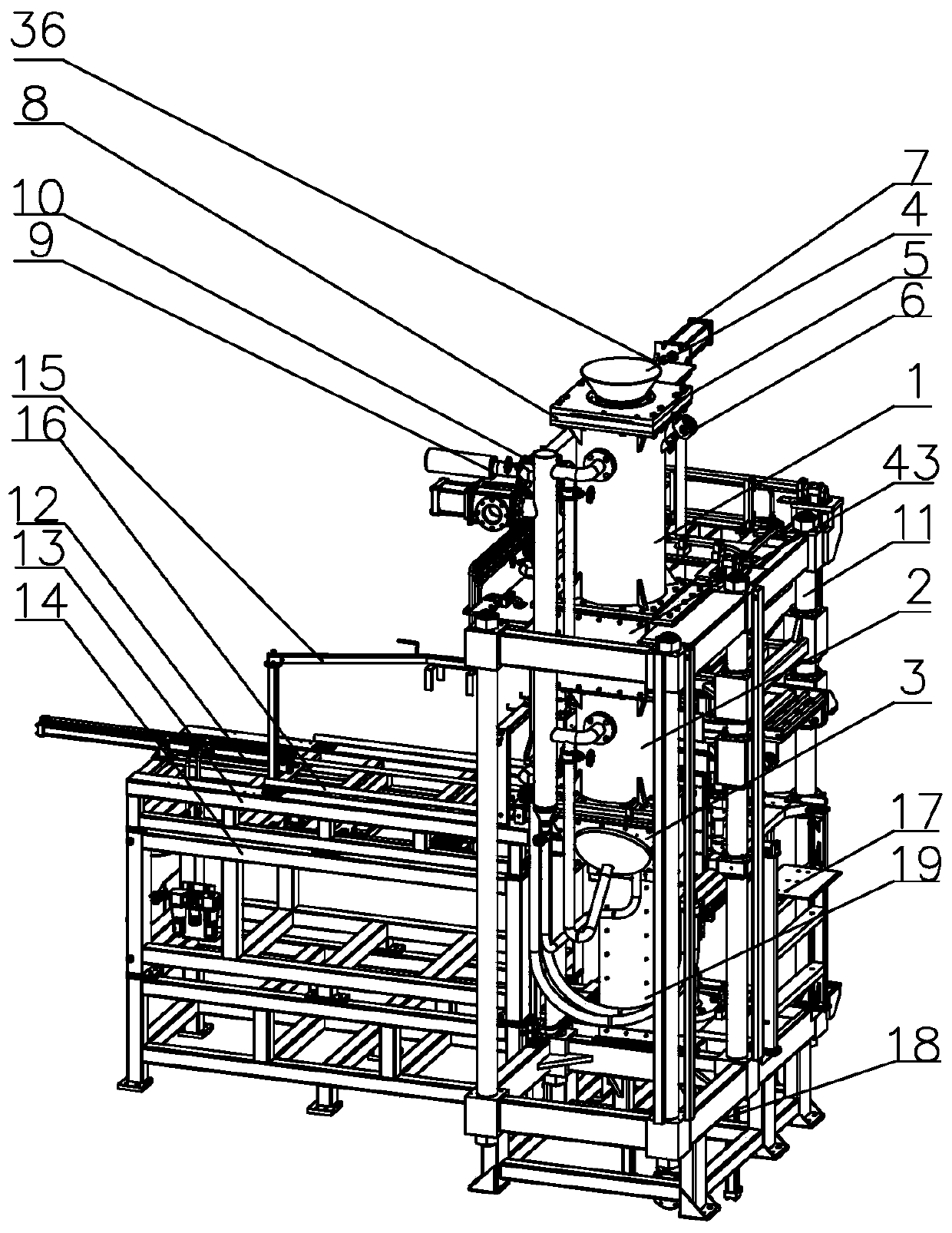

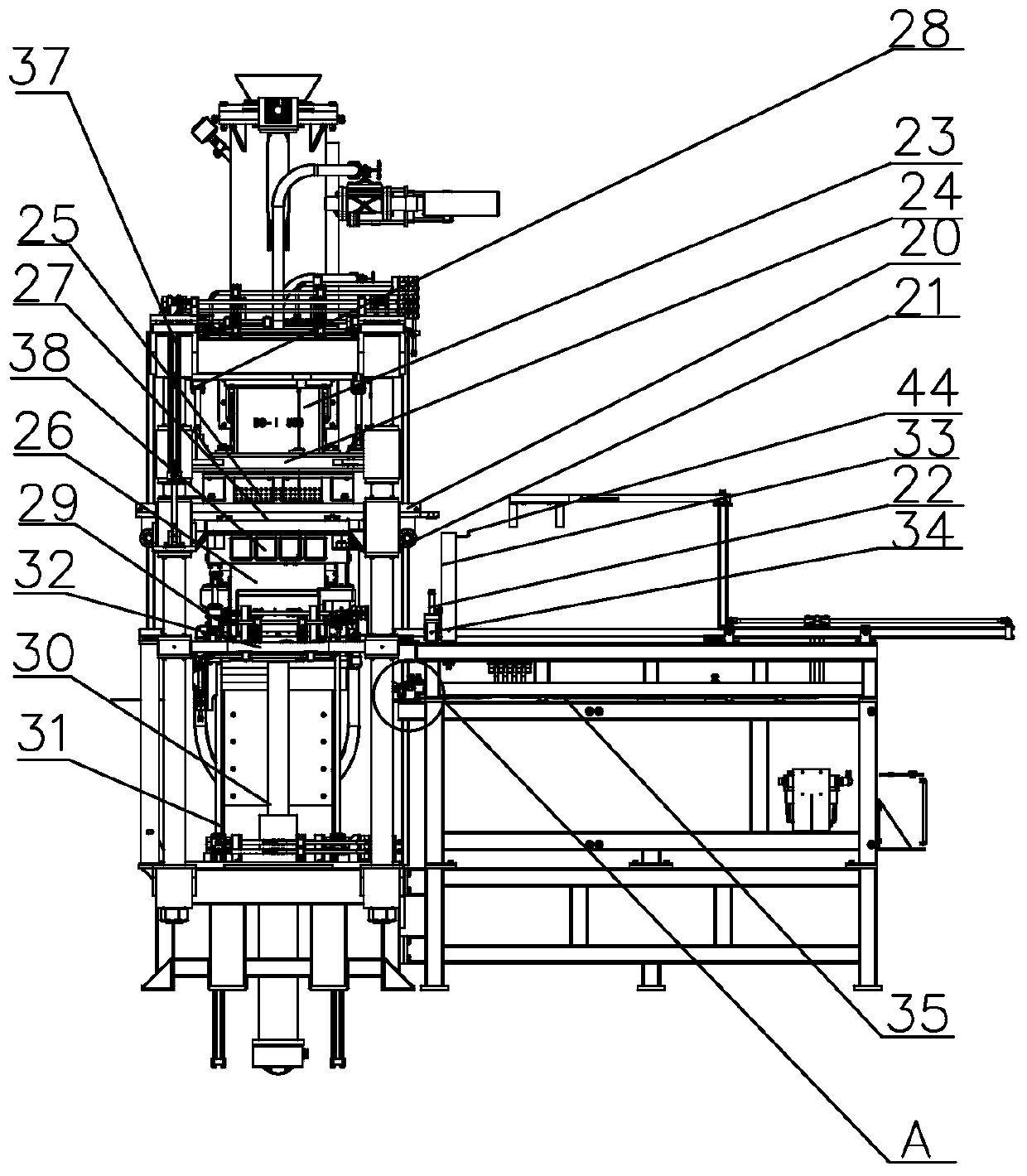

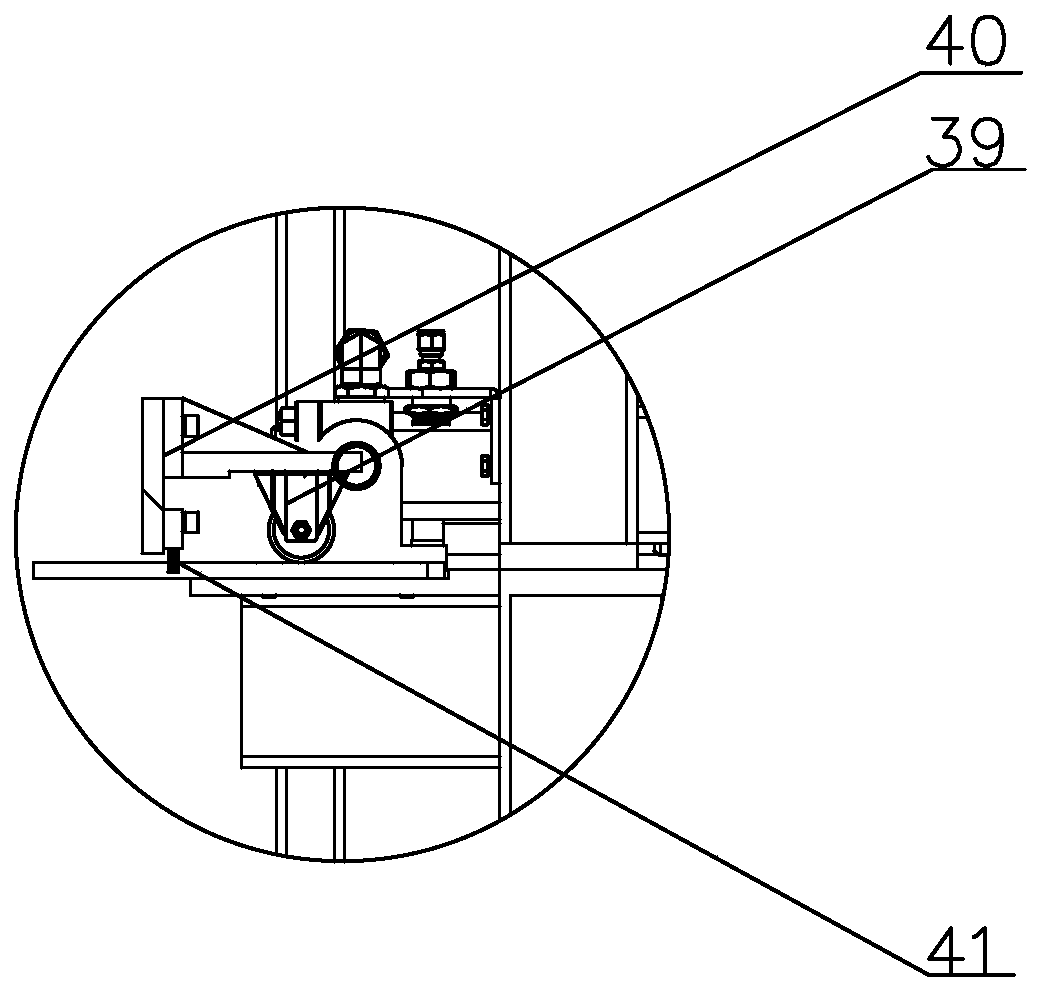

[0028] like figure 1 and 2 As shown, the present invention comprises a frame 18, six guide posts 11 fixed on the frame 18, a mounting frame fixedly connected to the frame 18, a sand feeding device fixed on the upper end of the frame 18, and a sand feeding device sealed and connected The sand tank body 1, the upper elbow 43 fixedly connected with the bottom of the upper sand tank body 1, the lower sand tank body 2 fixedly connected with the bottom of the upper elbow 43, the lower elbow 3 fixedly connected with the lower sand tank body 2, The upper gas storage bin 23 that is sealed with the upper elbow 43, the first mounting seat 24 that is slidingly connected with the guide post 11, the upper case 25 fixed on the first mounting seat 24, and the first mounting seat 25 for driving the upper case 25. Oil cylinder 28, be located at the template frame 27 below the first mounting seat 24 and be slidably connected with guide post 11, be used to drive the second oil cylinder 37 of tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com