Novel efficient casting device capable of achieving easy demoulding

A new type of technology that is easy to demould, applied in foundry equipment, casting molding equipment, mold boxes, etc., can solve the problems of difficult demoulding of the sand box, high cost, low molding efficiency, etc., to ensure the effect of molding and flexible use. , the effect of improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

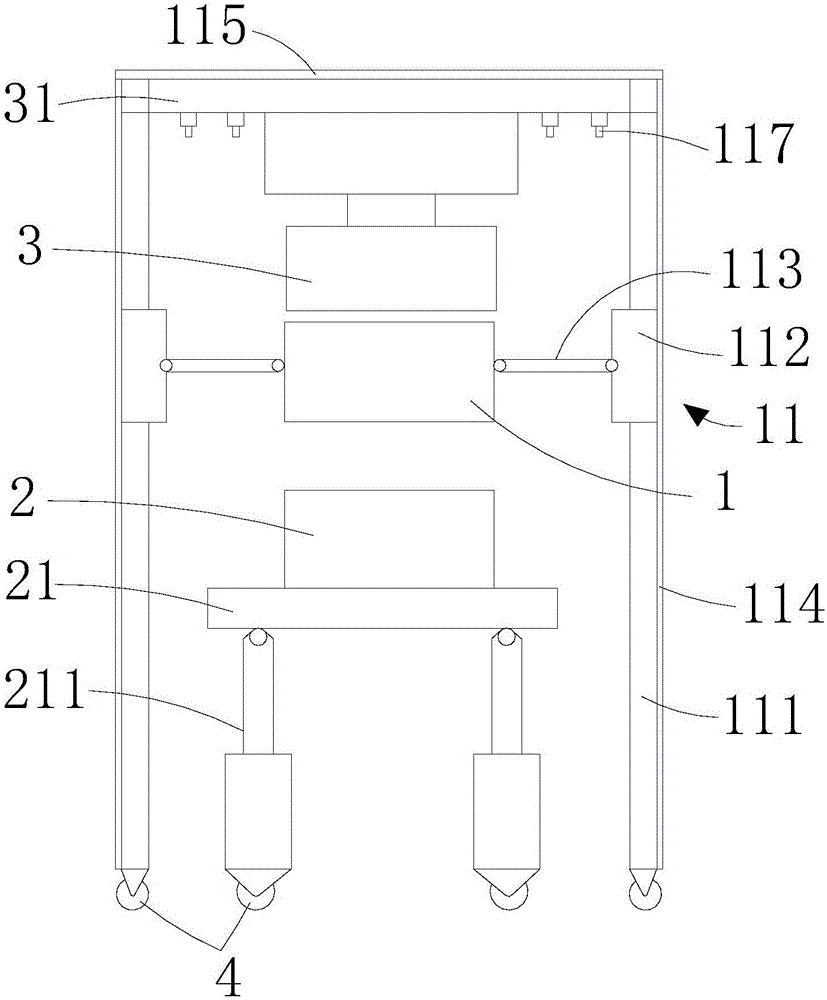

[0018] like figure 1 As shown, the present invention provides a kind of easy demoulding novel high-efficiency casting device, comprises upper sand box 1, lower sand box 2, upper sand box fixing frame 11, lower sand box supporting platform 21, and upper sand box fixing frame 11 comprises four A symmetrically arranged column 111, the middle part of the column 111 is equipped with a hydraulic lifting slider 112, and the hydraulic lifting slider 112 is connected with a cross arm 113, and one end of the cross arm 113 is connected to the hydraulic lifting slider 112 through a hinge. Hinged, the other end of the cross arm 113 is hinged to the upper sand box 1 through a hinge, the hydraulic compactor 3 is installed on the top of the column 11, and the bottom four corners ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com