Container flushing device for medical department

A technology of flushing device and container, applied in the field of medical supplies cleaning, can solve the problems of poor flushing effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

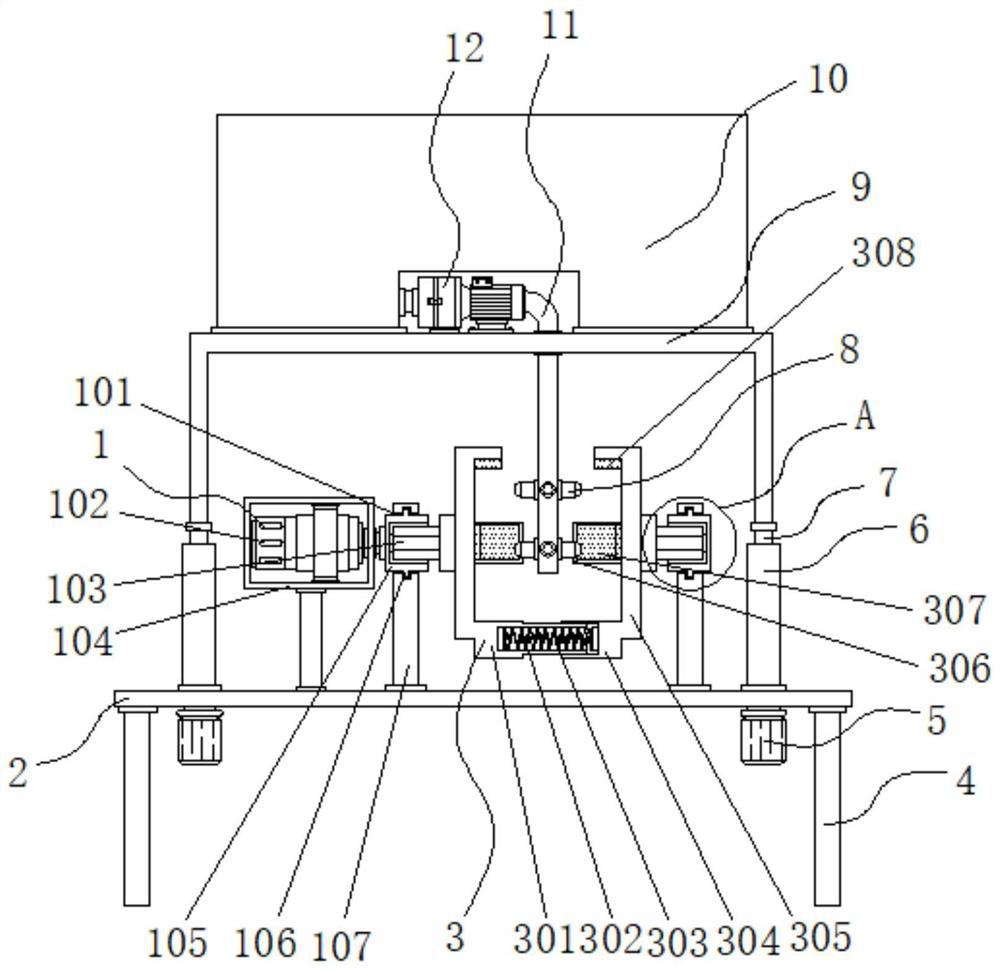

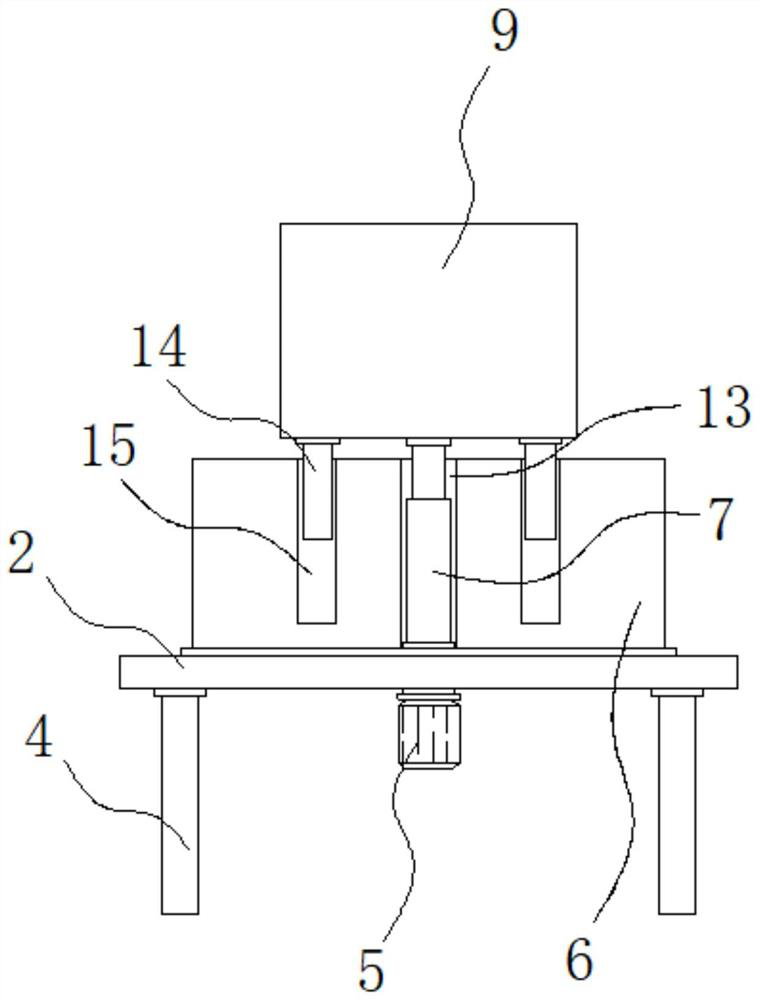

[0025] Example 1: See Figure 1-4 , a container flushing device for medical departments, including a horizontal plate 2 and legs 4, a set of legs 4 are fixedly connected to the four corners of the bottom end of the horizontal plate 2, and a dumping mechanism 1 is arranged on the top of the horizontal plate 2, and the tipping mechanism 1 One side is provided with a clamping structure 3, the top of the clamping structure 3 is provided with a lifting frame 9, the top of the lifting frame 9 is fixedly connected with a water tank 10, and the top of the lifting frame 9 is fixedly connected with a water pump 12, and the model of the water pump 12 is JET -1100, the input end of the water pump 12 runs through one side of the water tank 10 and communicates with the inside of the water tank 10, the output end of the water pump 12 is fixedly connected with the outlet pipe 11, and the outlet pipe 11 runs through the top of the lifting frame 9 and extends to the lifting frame 9 Inside, the ...

Embodiment 2

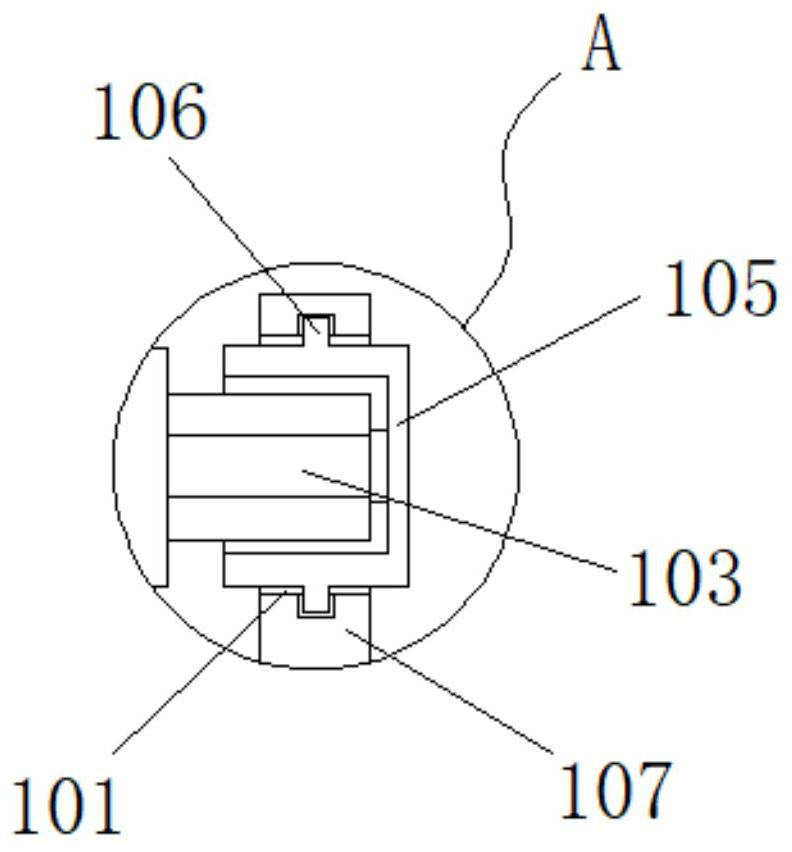

[0029] Embodiment 2: The dumping mechanism 1 is composed of a turning groove 101, a servo motor 102, a cross shaft 103, a fixed box 104, a cross sleeve groove 105, a limit ring 106 and a support plate 107, and the support plate 107 is fixedly connected to the top of the horizontal plate 2. On both sides, one side of the support plate 107 is inlaid with a turning groove 101, and the inside of the turning groove 101 is movably connected with a cross sleeve groove 105, and the outside of the cross sleeve groove 105 is fixedly connected with a limit ring 106, and the limit ring 106 is movable with the turn groove 101 Connection, the fixed box 104 is fixedly connected to one side of the top of the horizontal plate 2, the inside of the fixed box 104 is fixedly connected with the servo motor 102, the model of the servo motor 102 is HG-KN13J-S100, and the output end of the servo motor 102 runs through the fixed box One side of 104 extends to the outside of the fixed box 104 and is fixe...

Embodiment 3

[0032] Embodiment 3: The clamping structure 3 is composed of a first cavity 301, a limit cylinder 302, a spring 303, a second cavity 304, a clamping sleeve 305, a side plate 306, a first rubber pad 307 and a second rubber pad 308 , the clamping sleeve 305 is arranged at the bottom ends of both sides of the water outlet pipe 11, one side of the bottom end of the clamping sleeve 305 is fixedly connected with the first empty groove 301, and the other side of the bottom end of the clamping sleeve 305 is fixedly connected with the second empty groove 304 One side of the first empty slot 301 is fixedly connected with a spring 303, one side of the first empty slot 301 is fixedly connected with a limiting cylinder 302, the limiting cylinder 302 is movably connected with the second empty slot 304, and the spring 303 is connected with the second empty slot. The groove 304 is fixedly connected, and the two ends of the clamping sleeve 305 are respectively fixedly connected with a set of si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com