Automatic waste collecting and processing device of aluminum silicate silk floss throwing machine

A technology for automatic collection and processing devices, which can be used in the fields of rayon recycling, textile and paper making, sustainable manufacturing/processing, etc., and can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

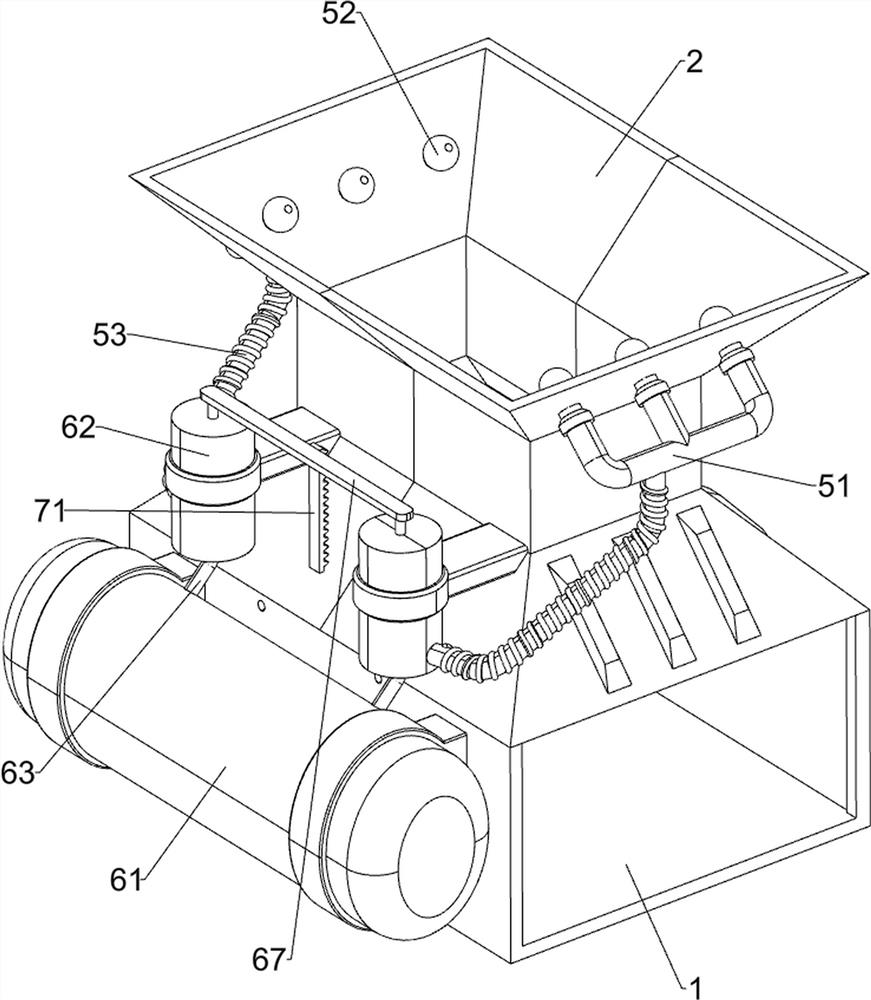

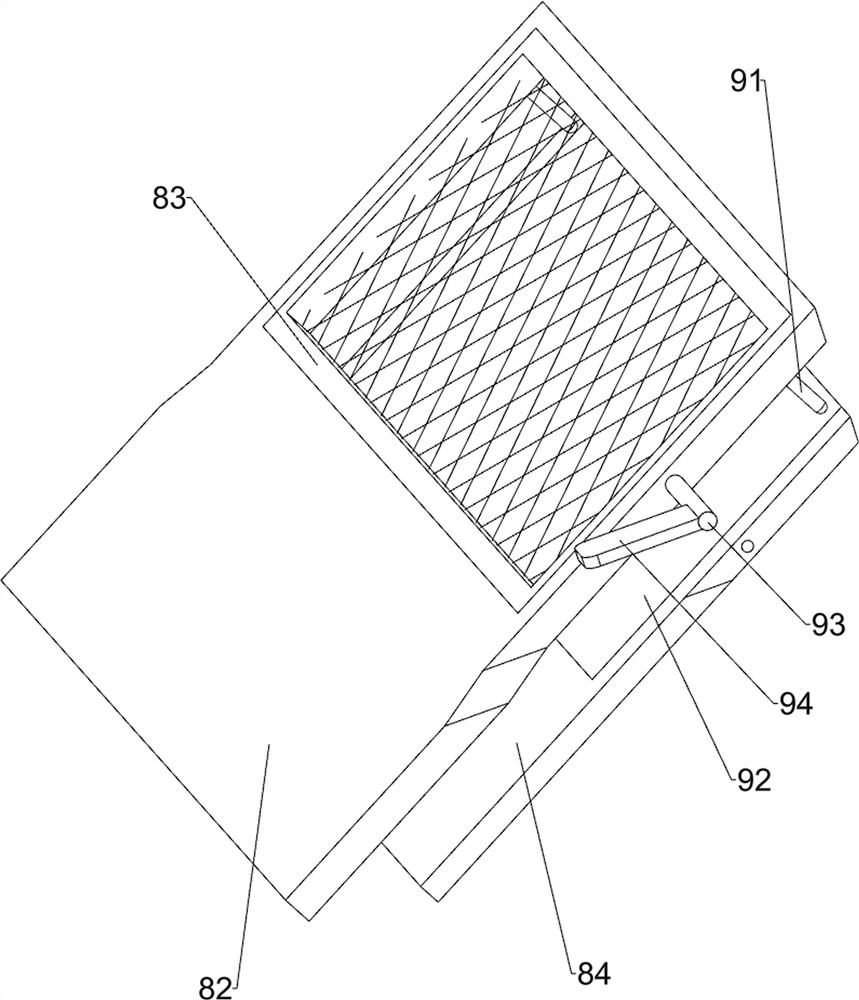

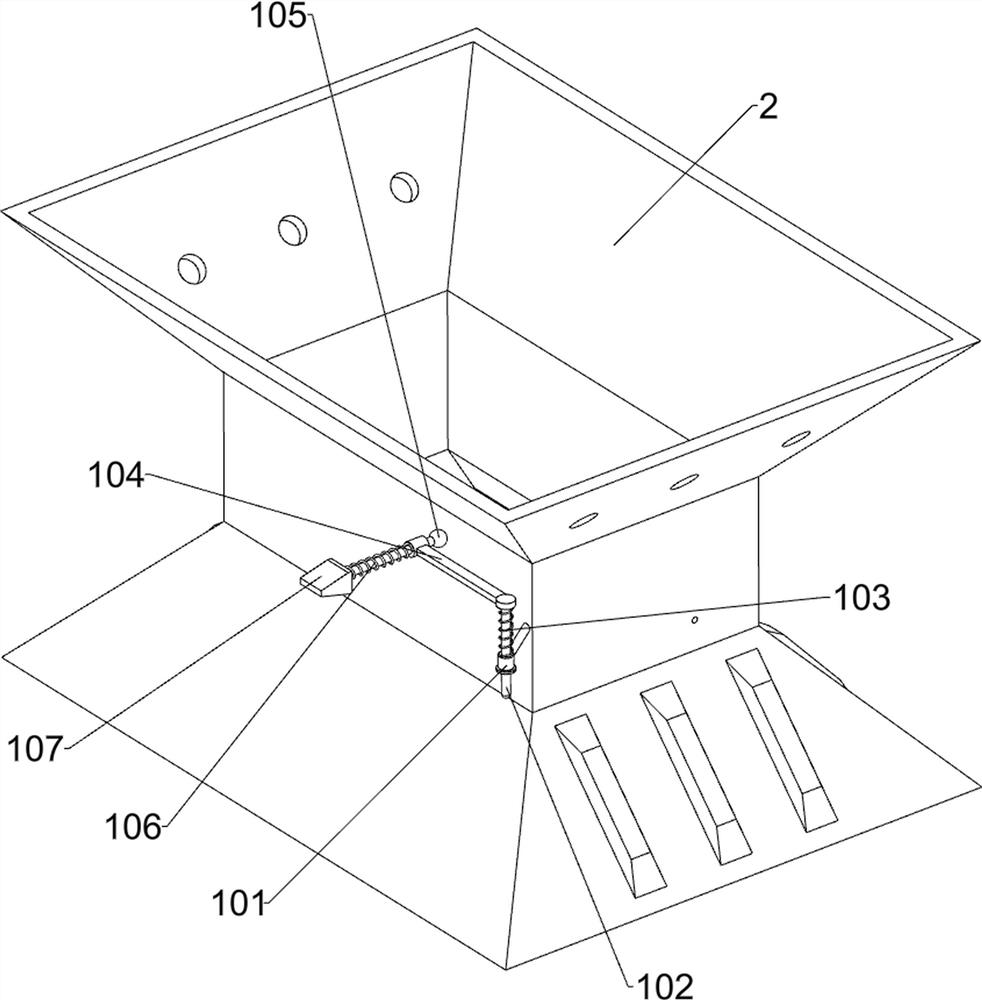

[0026] A kind of waste material automatic collection and processing device of aluminum silicate silk spinning machine, such as Figure 1-8 As shown, it includes a box body 1, a hopper 2, a collection frame 3, a handle 4, a water spray mechanism 5 and a water storage mechanism 6, the top of the box body 1 is provided with a hopper 2, and the box body 1 is detachably provided with a collection frame 3 A handle 4 is provided on the front side of the collection frame 3, a water spray mechanism 5 is provided on the hopper 2, and a water storage mechanism 6 is provided between the hopper 2 and the box body 1.

[0027] When using the device, the staff moves the equipment to the waste outlet of the aluminum silicate silk spinning machine, and the waste thrown out of the spinning machine enters the collection frame 3 through the hopper 2 for collection. 5. Spray water to cool down the waste. When spraying water, supply water to the water spray mechanism 5 through the water storage mech...

Embodiment 2

[0033] On the basis of Example 1, such as figure 1 , figure 2 with Figure 4 As shown, also includes lifting mechanism 7, and lifting mechanism 7 includes rack 71, first mounting plate 72, reduction motor 73 and sector gear 74, and connecting plate 67 middle part is provided with rack 71, and hopper 2 left side is provided with the first A mounting plate 72, the first mounting plate 72 is provided with a reduction motor 73, the output shaft of the reduction motor 73 is provided with a sector gear 74, and the sector gear 74 cooperates with the rack 71.

[0034]When using the device, the staff starts the deceleration motor 73, and the deceleration motor 73 rotates to drive the sector gear 74 to rotate. When the sector gear 74 rotates to mesh with the rack 71, the sector gear 74 rotates to drive the rack 71 to move upward, and the rack 71 The upward movement drives the connecting plate 67 to move upward, and the upward movement of the connecting plate 67 drives the piston 64 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com