Automatic control device of reverse tubular column coupling of belt pressure operation device

An automatic control device, a technology for pressurized operation, applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problem of inaccurate alarm of coupling alarm, complicated manual operation, and inaccurate judgment of operators And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

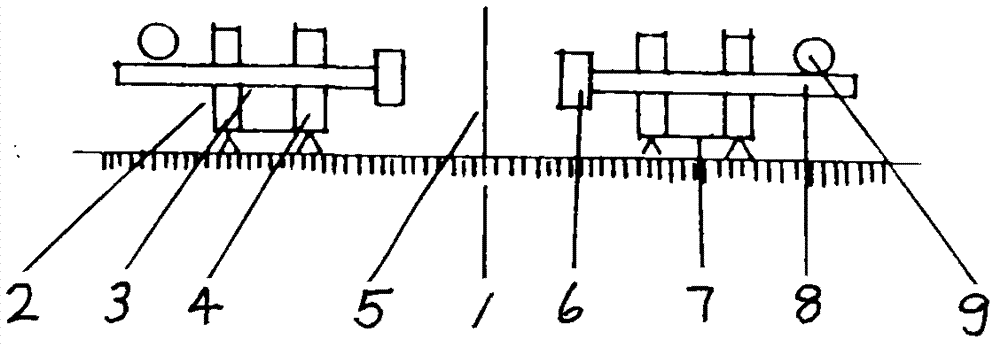

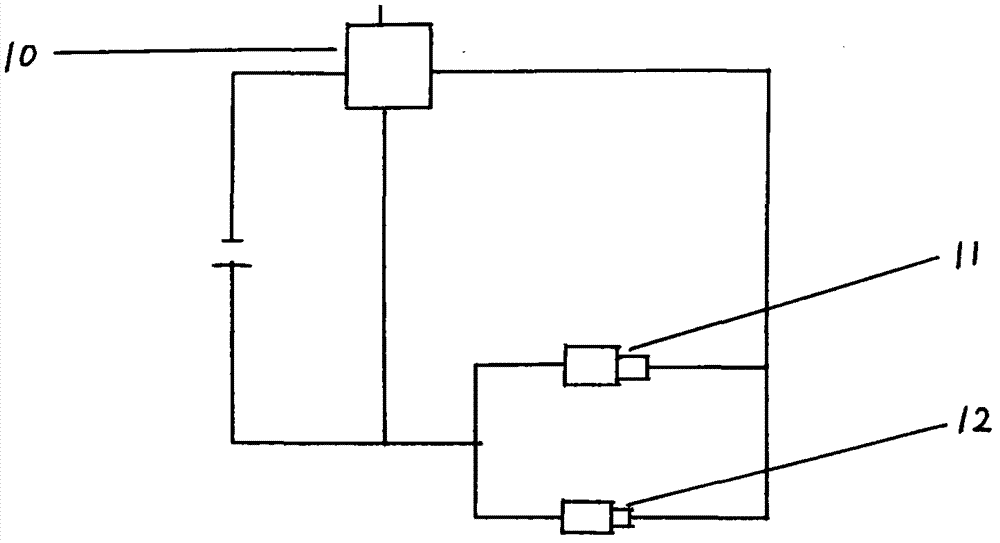

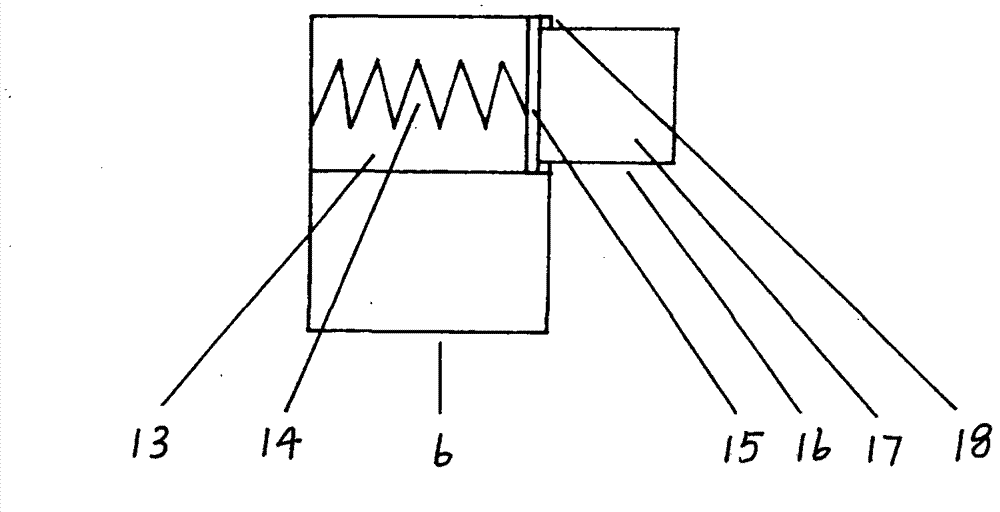

[0015] In the picture: the automatic control device of the inverted pipe column coupling with pressure working device is composed of a coupling reporting device, a signal receiving control device, a control structure, a timing switch, and a connector; a control structure is set on the operating platform of the remote control device , That is, the two motors are fixedly connected to the operating platform (1) of the remote control device, the motor shaft is fixedly connected to the gear (9), and the two supporting bodies are fixedly connected to the operating platform of the remote control device. The supporting body (2) is formed by the connecting plate ( 7), the support plate (4), the two ends of the connecting plate are connected to the two support plates perpendicularly, there is a connecting square hole in the middle of the support plate, the center lines of the two connecting square holes are on the same straight line, and the center line is perpendicular to the support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com