Processing technology of contact seat

A processing technology and contact seat technology, which is applied in the direction of engine lubrication, engine components, lubricating parts, etc., can solve the problems of inconvenient lubricating oil treatment, and achieve the effects of reducing labor intensity, easy pouring, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The following is attachedFigure 1-6Give further details on this application.

[0041]The embodiment of the application discloses a processing technology of a contact seat, including the following steps:

[0042]S1, material preparation;

[0043]S2. Roughing: Roughing the cylindrical hole 11 through a lathe;

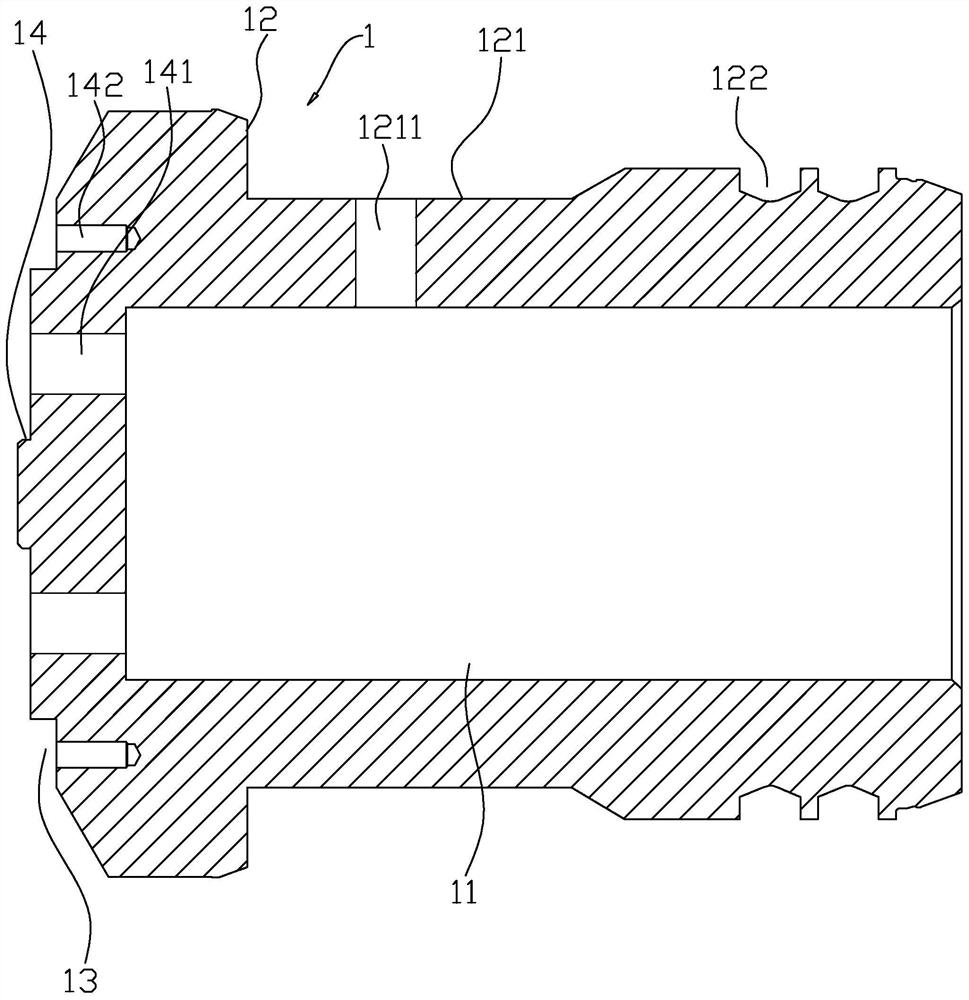

[0044]S3. CNC turning: boring the cylindrical hole 11 and turning the first annular groove 12, the second annular groove 13, the third annular groove 14, the fourth annular groove 121, and the fifth annular groove 122 through the numerical control lathe;

[0045]S4. Machining center: processing the first through hole 1211, the second through hole 141 and the threaded hole 142;

[0046]S5. Electro-engraving; electro-engraving is performed in the designated area of the end of the second annular groove 13 close to the first annular groove 12;

[0047]S6. Silver plating: silver plating is performed on the fifth annular groove 122;

[0048]S7. Packaging.

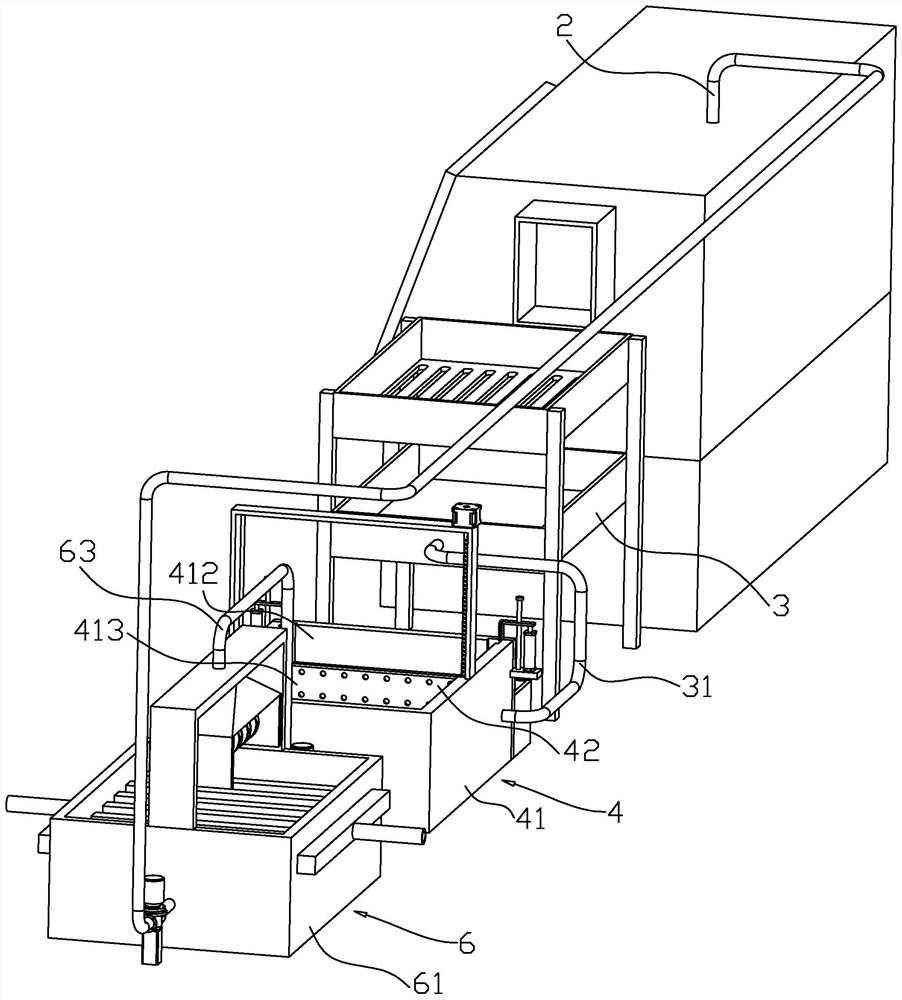

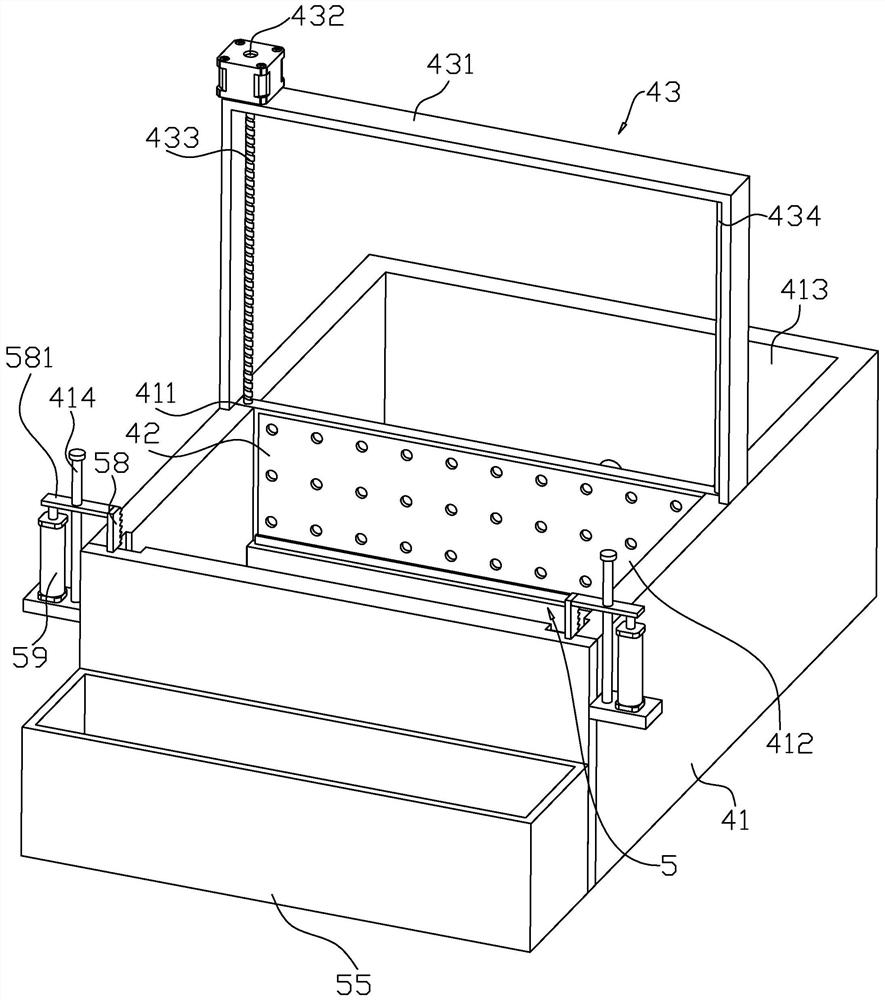

[0049]Such asfigure 2 withimage 3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com