Small automatic thresher

A threshing machine, automatic technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of mechanization and low technology level, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

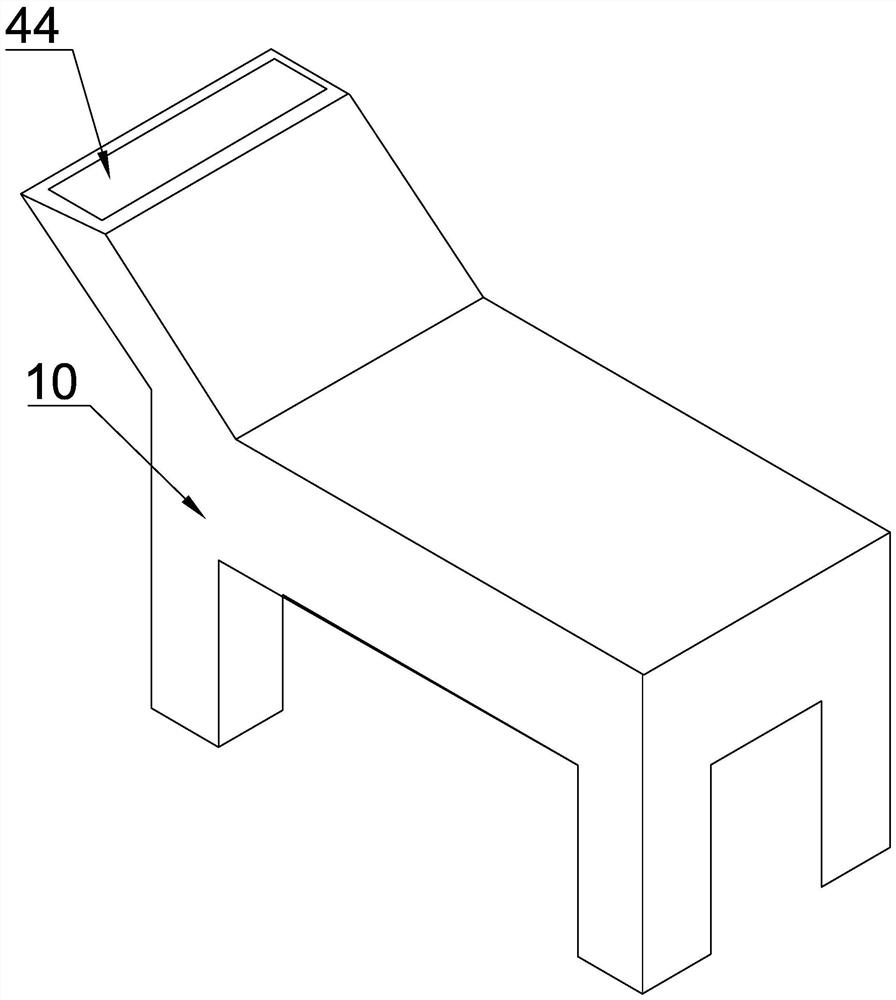

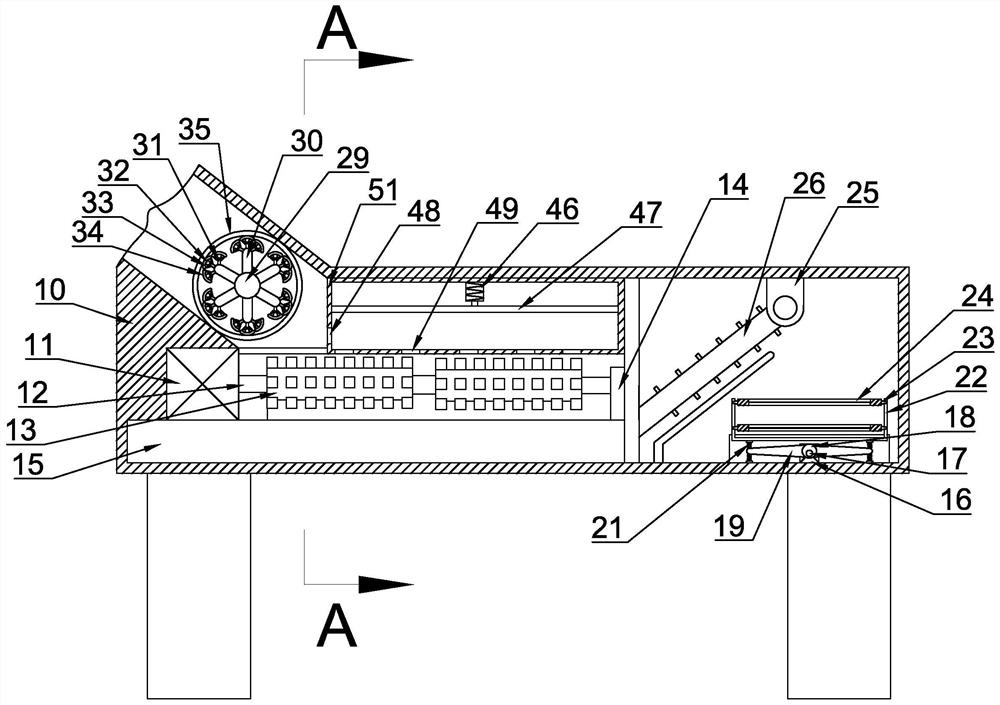

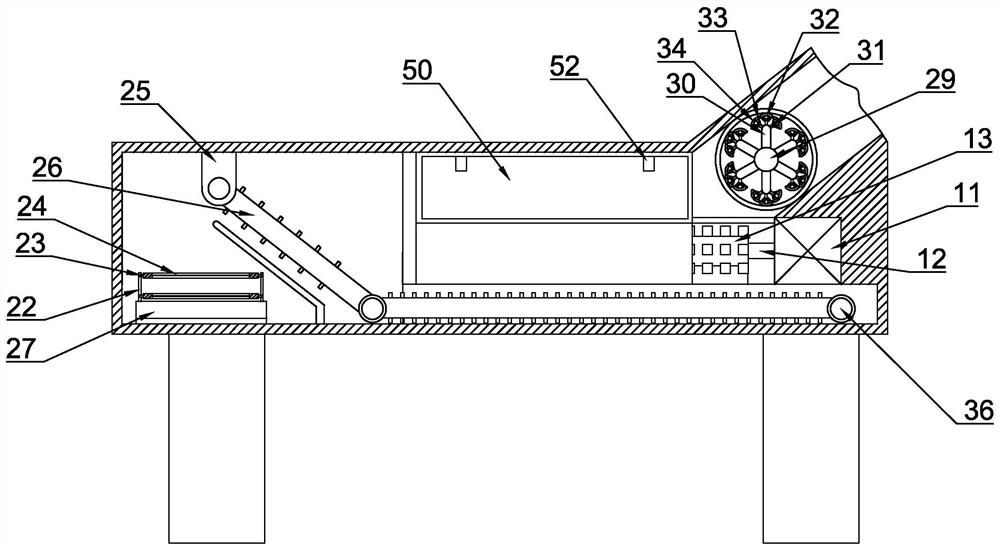

[0026] Such as figure 1 As shown, a housing 10 is included. The upper left side of the housing 10 is provided with a feed chamber for delivering materials to the interior of the chamber. The bottom of the housing 10 is provided with a working chamber for threshing rice. The upper half of the housing 10 There is a garbage chamber at the bottom, and a rice transfer device is provided on the rear side of the housing 10 to transfer the threshed rice to other chambers. The right side of the housing 10 is provided with a screening device for removing rice, sundries and fine stones. Separation, the back of the screening device is provided with a discharge port 28, and the rice that has been screened is sent out of the chamber.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com