In-barrel compacting device for radioactive solid waste

A solid waste and radioactive technology, applied in radioactive purification, nuclear engineering, etc., can solve the problems of increasing the exposure of operators to radioactive pollution, large dimensions, and large floor space, etc., to achieve overall height reduction, small installation length, and occupied space. The effect of space reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical features, features, technical effects and design purposes of the present invention more obvious and understandable, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific implementation methods.

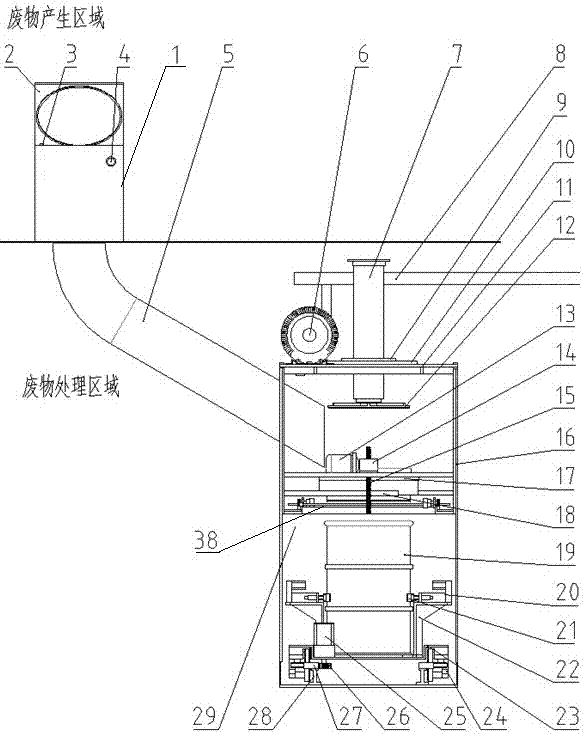

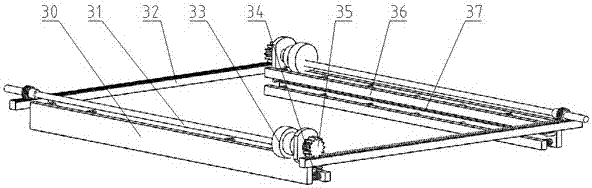

[0027] Such as figure 1 and 2 As shown, the embodiment of the present invention provides a compacting device in a solid radioactive waste barrel, including:

[0028] Frame 11, the side panel of described frame 11 is provided with waste chute 5, and waste chute 5 communicates with feed inlet 1, and described feed inlet 1 is provided with lid 2 that can be opened and closed up and down, and after lid 2 covers airtight;

[0029] The front panel of the frame 11 is provided with an inlet and outlet barrel mouth, and the inlet and outlet barrel mouth is provided with a flashboard door 29, and the frame on both sides of the flashboard door 29 is provided with a guide groove 16, and the flashbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com