Compactor system and method

A technology of compactor and compaction force, applied in the direction of presses, manufacturing tools, etc., can solve problems such as damage, equipment damage, personnel, manipulation and transportation difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

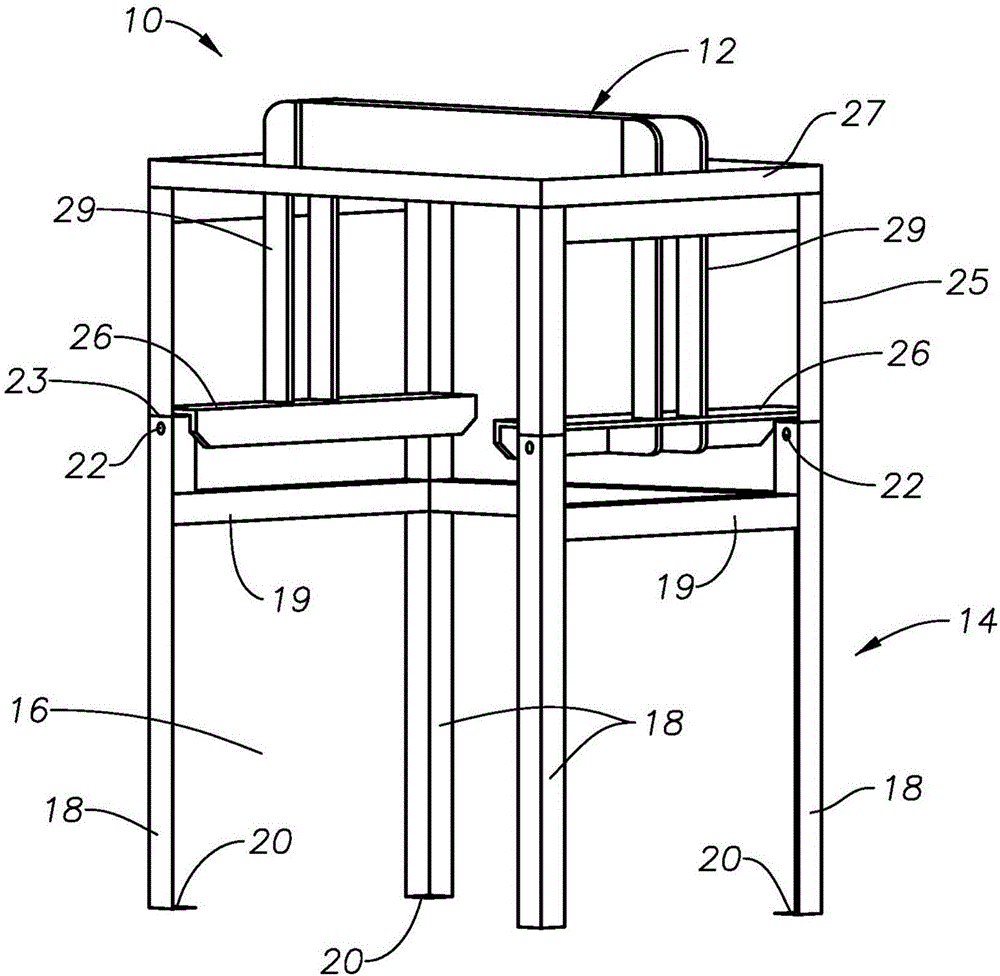

[0060] The compactor system may include a compaction unit having a frame assembly 10 such as image 3 and Figure 4 shown. The frame assembly 10 may include a movable upper frame portion 12 and a fixed lower frame portion 14 . The frame assembly 10 may also include a cavity 16 . The fixed lower frame portion 14 may include legs 18 interconnected by struts 19 in spaced relationship. Legs 18 may be configured in a square, rectangular, or other arrangement to form cavity 16 . The fixed lower frame part 14 supports the movable upper frame part 12 . A foot member 20 may be operably connected to a lower end of each of the legs 18 . Footing members 20 may be used to secure frame assembly 10 to a base structure to stabilize the compactor system when the ship is in motion. The base structure may be the base of a marine vessel such as a ship or an offshore installation.

[0061] The upper end of each leg 18 of the lower fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com