Secondary dynamic balance checking structure and method used for DC motor

A DC motor and balancing technology, which is applied in the field of vibration reduction and noise reduction, can solve the problems of increased difficulty in reaching the standard and poor dynamic balance effect, and achieve the effects of improving performance, meeting structural vibration acceleration requirements, and improving dynamic balance accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

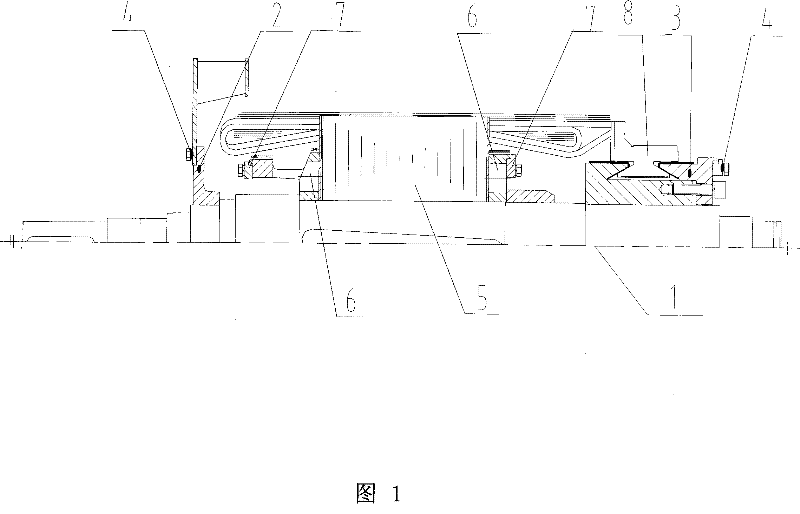

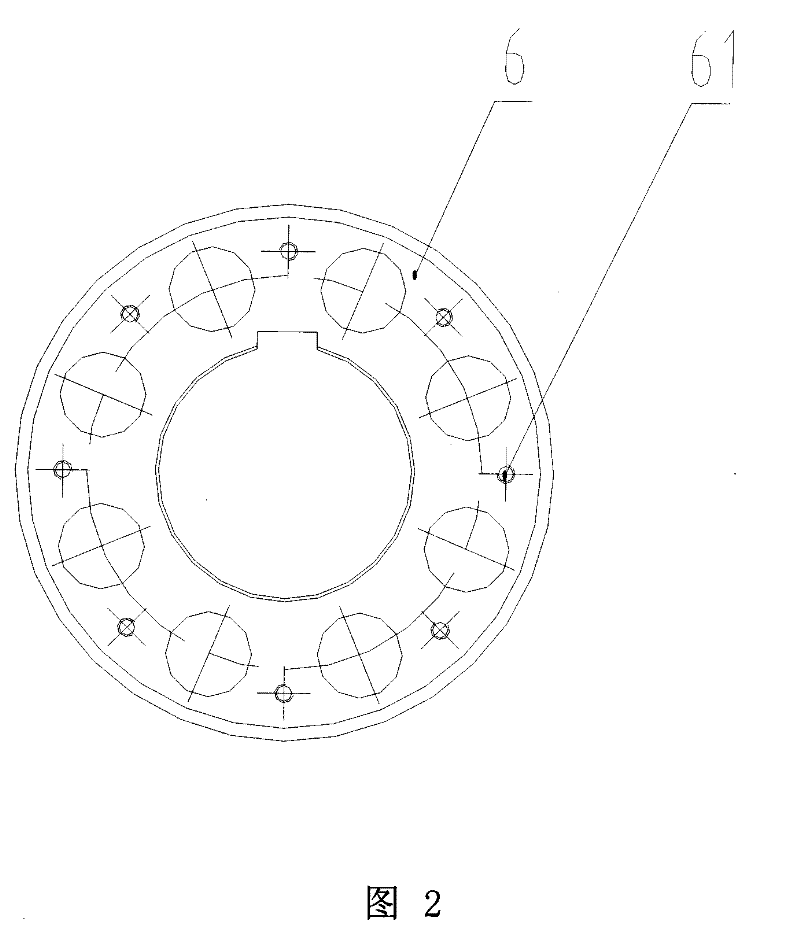

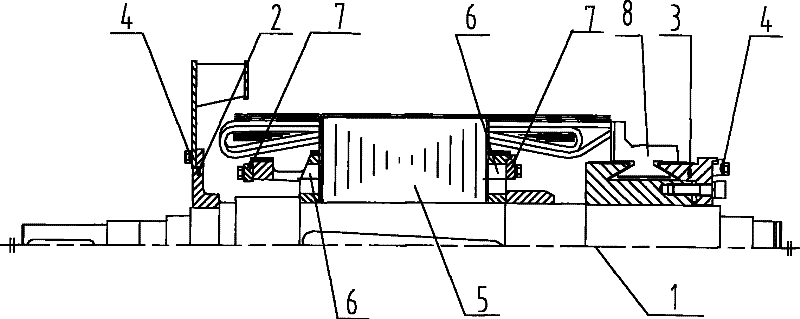

[0017] see figure 1 and figure 2 , the figure shows a kind of calibration dynamic balance structure for a DC motor of the present invention, including a motor body 1, on the balance seat 2 and the commutator pressure ring 3 at the two ends of the armature of the motor body 1, respectively The first balance weight 4 is installed, and there is an iron core pressure ring 6 at both ends of the iron core 5, and the second balance weight 7 installed on the two iron core pressure rings 6 respectively, and the end faces of the two iron core pressure rings 6 Several balance weight installation screw holes 61 are also provided to install the second balance weight 7 .

[0018] A secondary calibration dynamic balancing method for DC motors of the present invention comprises the following steps:

[0019] The first calibration and dynamic balancing step, that is, when the stacking o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com