Tunnel excavation water pressure blasting construction method

A technology of hydraulic blasting and tunnel excavation, which is applied in blasting, tunneling, earthwork drilling and mining, etc. It can solve the problems of polluting the environment and failing to make full use of explosives, so as to improve economic benefits, improve the construction environment in the cave, and blasting effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

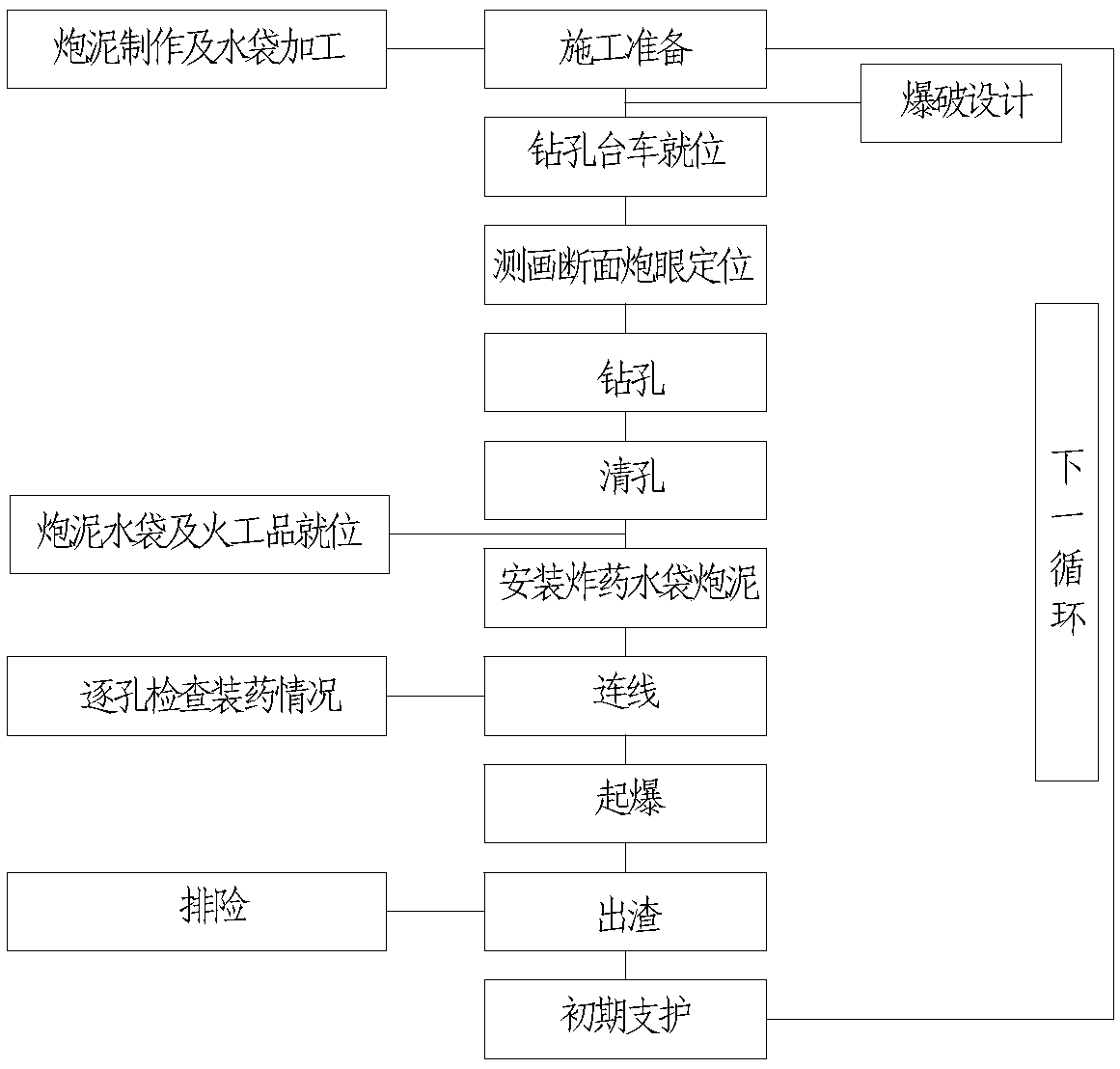

[0046] Such as figure 1 As shown, the tunnel excavation hydraulic blasting construction method includes the following steps:

[0047](1) The trolley is in place and the risk is removed

[0048] After the upper cycle construction is completed, the excavation jumbo is first put in place, and then the loose dangerous stones are manually cleaned to ensure the safety of the construction process;

[0049] (2) Measuring cloth holes and drilling holes

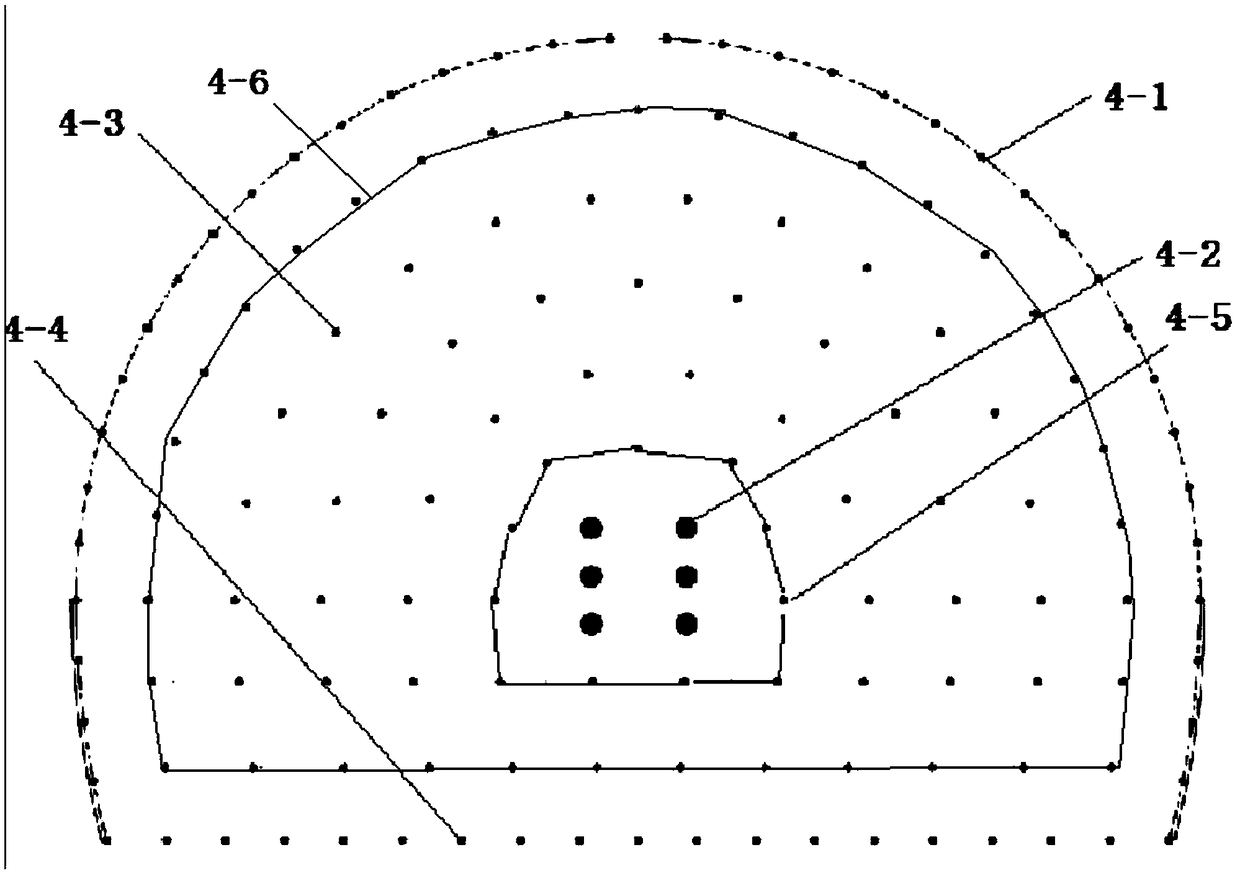

[0050] Such as image 3 As shown, use the total station to accurately determine the excavation contour line, the peripheral eye 4-1 and the position of the cutting eye 4-2 on the face, and use the contour line to determine the expansion hole 4-5, auxiliary The position of eye 4-3, inner ring eye 4-6, bottom plate eye 4-4; auxiliary eye 4-3 position; the drilling holes are divided and fixed, and the drilling is carried out strictly according to the hole position, and the hole positions are distributed on the palm surface at intervals...

Embodiment 2

[0072] Such as figure 1 As shown, the tunnel excavation hydraulic blasting construction method includes the following steps:

[0073] (1) trolley in place and risk removal are the same as in embodiment 1

[0074] (2) Measuring cloth eye and drilling is the same as embodiment 1

[0075] (3) Install explosives, water bags and gun mud

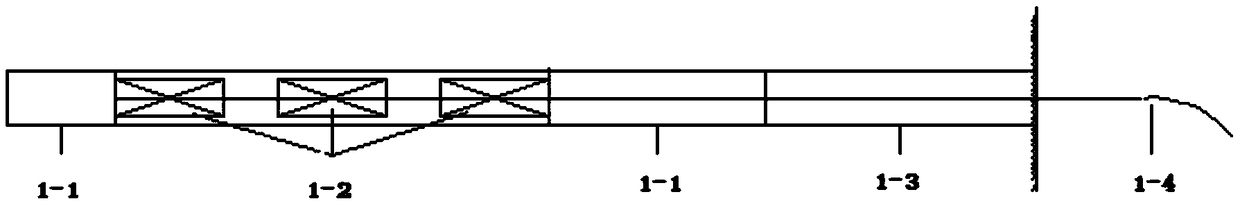

[0076] Such as figure 2 As shown, before installing explosives 1-2, use PVC pipe through holes to confirm that the hole depth meets the requirements;

[0077] Peripheral hole 4-1 is excavated to set the arc periphery of tunnel face, and peripheral hole 4-1 adopts the following method to install explosives 1-2, water bag 1-1 and gun mud 1-3: Put into a water-saving bag 1-1, then install the explosive 1-2 with a wooden pole, and the peripheral eye 4-1 adopts air-spaced, uncoupled charge, and the amount of charge in the fundus part is higher than that in other parts; The orifice is 80cm, then put 2 water-saving bags 1-1, and then use the gun mu...

Embodiment 3

[0089] Such as figure 1 As shown, the tunnel excavation hydraulic blasting construction method includes the following steps:

[0090] (1) trolley in place and risk removal are the same as in embodiment 1

[0091] (2) Measuring cloth eye and drilling is the same as embodiment 1

[0092] (3) Install explosives, water bags and gun mud

[0093] Such as figure 2 As shown, before installing explosives 1-2, use PVC pipe through holes to confirm that the hole depth meets the requirements;

[0094] Peripheral hole 4-1 is excavated to set the arc periphery of tunnel face, and peripheral hole 4-1 adopts the following method to install explosives 1-2, water bag 1-1 and gun mud 1-3: Put into a water-saving bag 1-1, then install the explosive 1-2 with a wooden pole, and the peripheral eye 4-1 adopts air-spaced, uncoupled charge, and the amount of charge in the fundus part is higher than that in other parts; The orifice is 80cm, then put 2 water-saving bags 1-1, and then use the gun mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com