Design method for rear drive axle of micro-surface automobile with low noise

A technology of rear drive axle and design method, which is applied in vehicle suspension/shock absorbing mechanism testing, measurement of ultrasonic/sonic wave/infrasonic wave, measuring device, etc. It can solve the problems of large vibration and noise of rear drive axle and affect automobile NVH, and achieve vibration Effects of speed reduction and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0018] The invention provides a method for designing a rear drive axle of a low-noise micro-surface automobile, comprising the steps of:

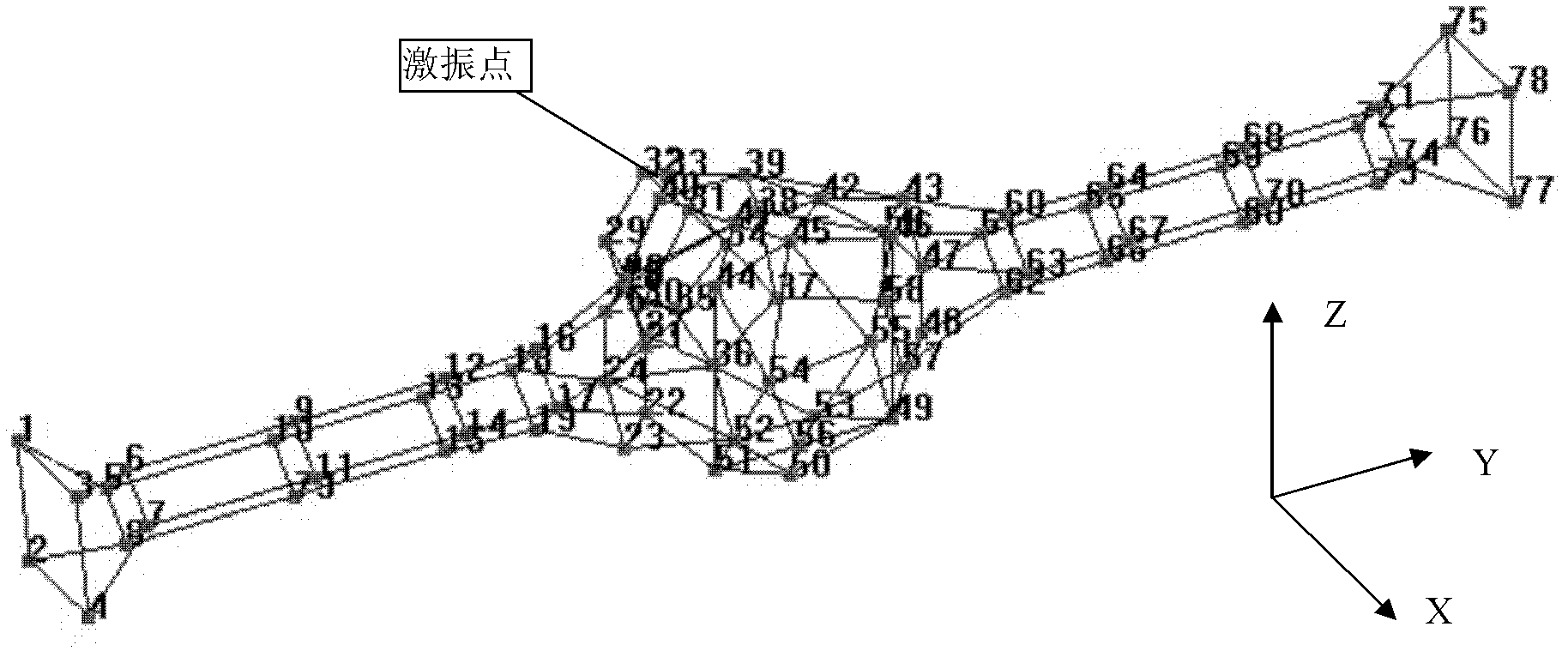

[0019] Step 1. Set 80 vibration measuring points on the rear axle housing. These 80 vibration measuring points are evenly arranged on the rear axle housing. The specific vibration measuring points are as follows: figure 1 As shown; each vibration measuring point is equipped with a vibration sensor. Before carrying out the experiment, each sensor should be calibrated. For example, set the filtering frequency to 2000Hz, the sampling frequency to 5000Hz, the number of data sampling blocks to 4, and the program-controlled magnification factor to 4.

[0020] Step 2. Set the hammer excitation point directly above the main reduction part of the rear axle, that is, near the 40th vibration measurement point, apply percussion a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com