Front shell of vehicle engine

A vehicle engine and front cover technology, applied in the direction of engine components, machines/engines, shells, etc., can solve the problems of large engine radiation noise, unreinforced, low elastic modulus, etc., to reduce local resonance and surface radiation noise, Improvement of local mode frequency and NVH performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

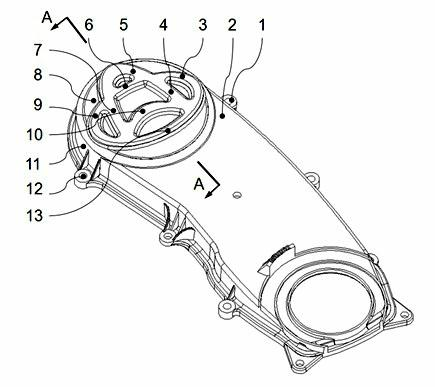

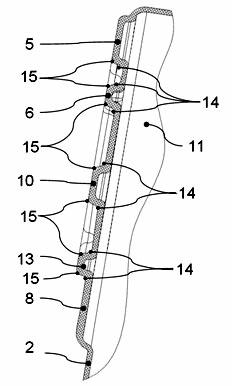

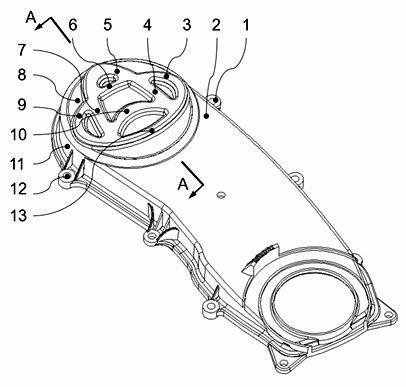

[0010] Such as figure 1 As shown, the front cover structure mainly includes the front cover 2 and inner and outer reinforcing ribs. There is a circular table top 8 on the top of the outer surface of the front cover 2, and the height of the circular table 8 on the basis of the front cover 2 is 4mm~6mm. Four arc-shaped outer ring reinforcement ribs 3, 5, 9, 13 and four arc-shaped inner ring reinforcement ribs 4, 6, 7, 10 are arranged on the circular table top 8, and eight ribs are formed on the top circular table top 8 Stable structure, the height of each rib is 4mm~6mm. The outermost ends of the outer ring reinforcement ribs 3, 5, and 9 are connected to the side wall 11 of the front cover 2, and the outer ring reinforcement ribs 3, 9, 13 and the inner ring reinforcement rib 6 have a width of 7 mm to 13 mm, and the combination forms an oval shape. The long ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com