Method for preventing vibration of smooth blasting in tunnel

A technology of smooth blasting and tunneling, applied in blasting and other directions, can solve problems such as uncertainty in the construction of vibration damping trenches, and achieve the effects of reducing vibration and damage, forming flat, and reducing vibration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

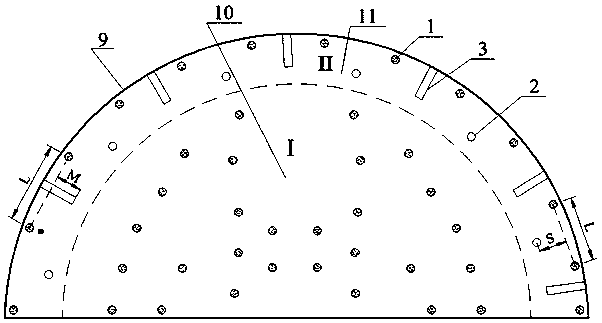

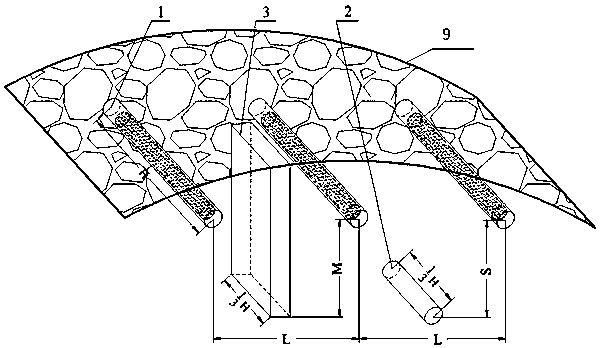

[0047] Such as figure 1As shown, the number of peripheral holes 1 in this embodiment is 13, which are arranged according to the interval between the vibration-damping holes 2 and the vibration-damping grooves 3, and each of the vibration-damping holes 2 is located between two adjacent peripheral holes 1, each In the setting method in which the vibration-damping grooves 3 are respectively located between two adjacent peripheral holes 1, the number of vibration-damping holes 2 is 6, and the number of vibration-damping grooves 3 is also 6. In this example, the line distance L between the two adjacent peripheral holes 1 is 0.6m, and the vertical distance between the damping hole 2 and the two adjacent peripheral holes 1 is S, S=0.4L= 0.24m, so the damping hole 2 is set on the mid-perpendicular line 0.24m away from the line connecting two adjacent peripheral holes 1.

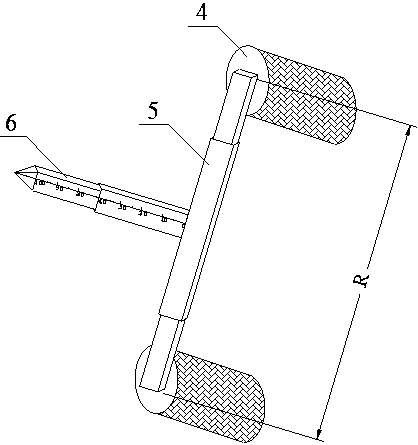

[0048] The damping groove 3 is a square shape, the length of the short side, that is, the width of the damping gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com