Noise reduction structure of porous plate

A technology of perforated plate and structure, which is applied in the direction of sound-absorbing devices, sound-generating devices, pipes/pipe joints/fittings, etc., which can solve the problems of performance degradation, noise reduction performance, and large overall volume, and achieve high noise reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

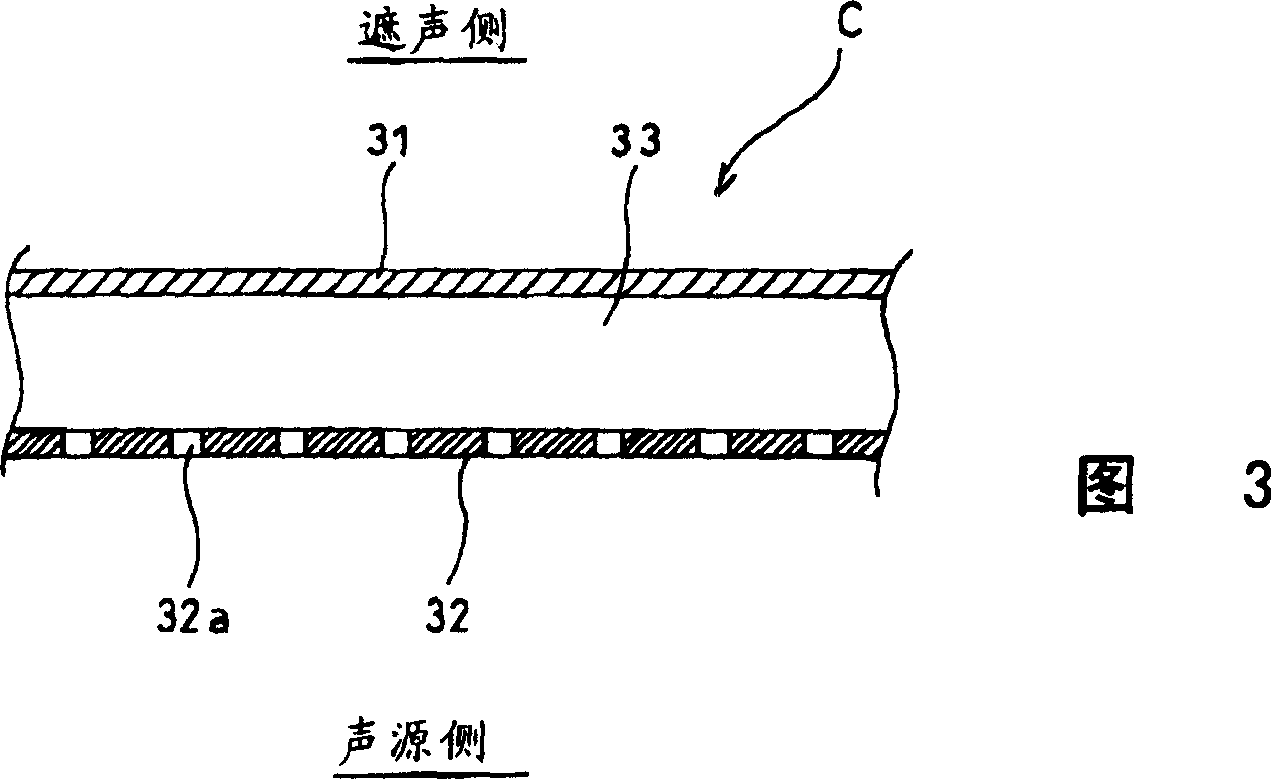

[0030] Embodiments of the invention will be described below. 4a and 4b are diagrams showing a first embodiment of the present invention. 4a and FIG. 4b, the noise reduction structure D has a cylindrical piping 41, a porous plate 42 extending in the axial direction of the piping 41 inside the piping 41 and dividing the cross-section of the piping 41. The piping path 41 partitioned by the plate 42 is partitioned by a partition plate 43 into a plurality of small chambers 44 in the axial direction of the piping path.

[0031] The piping line 41 is formed in the middle of the air supply or exhaust piping lines of compressors, turbines, pumps, power machines, and the like. The piping path 41 has a long shape with a circular cross section. Gas that is impacted by air supply or exhaust passes through the piping line 41 . The perforated plate 42 has a plate shape and is arranged parallel to the axial direction of the piping path 41 . With this arrangement, the perforated plate 42 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com