Graphene and stone tailing based foaming light heat insulation board and preparation method thereof

A technology of graphene and thermal insulation boards, which can be applied to clay products, ceramic products, and other household appliances. The effect of fire prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

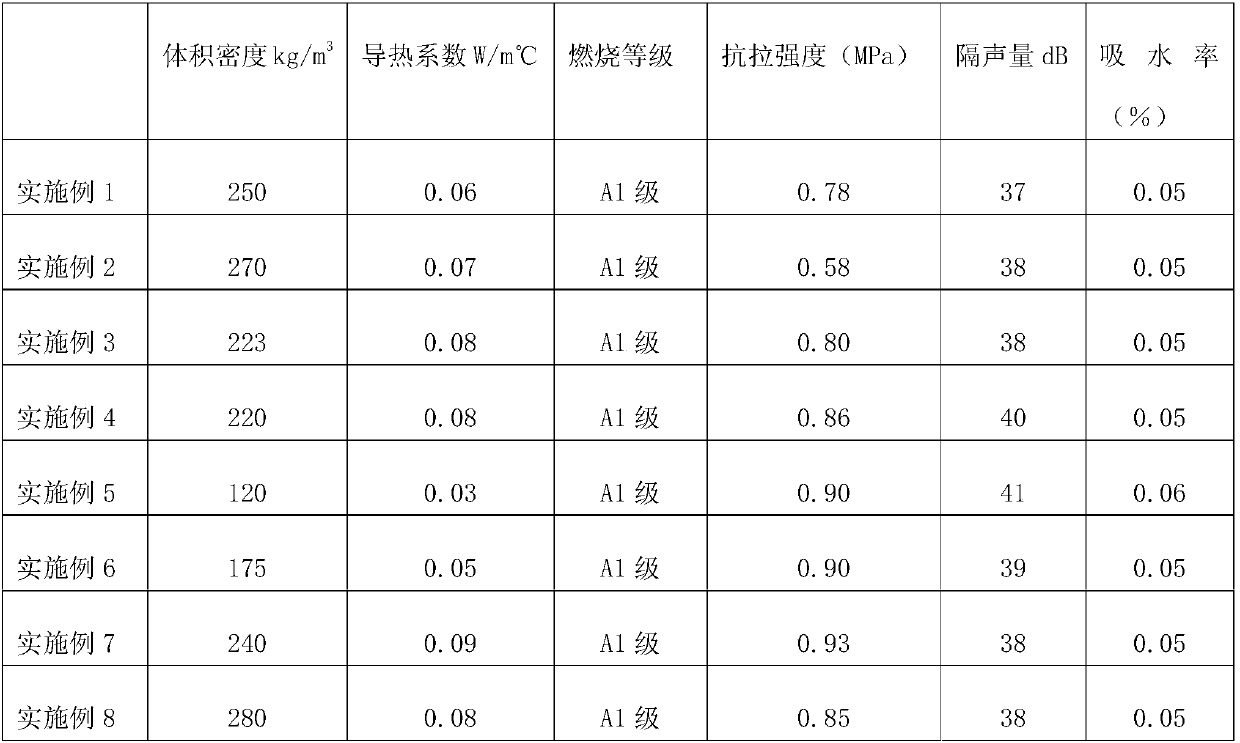

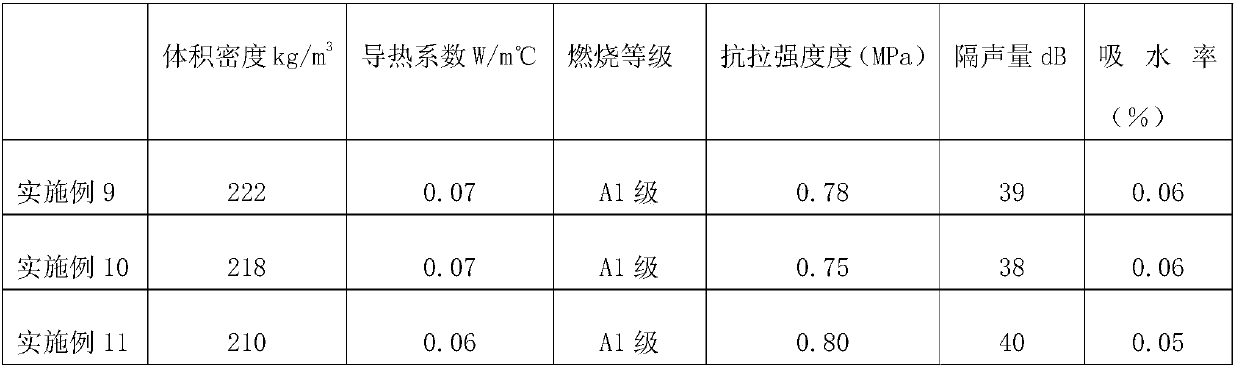

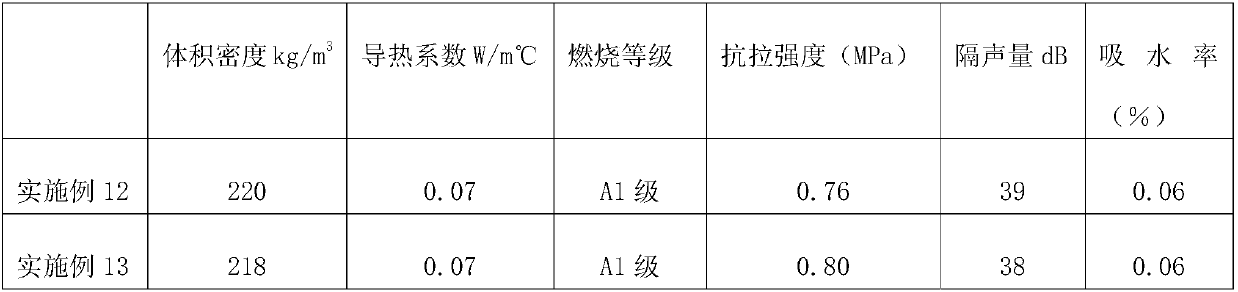

Examples

Embodiment 1

[0038] A foamed lightweight insulation board based on graphene and stone tailings, made of the following components by weight percentage:

[0039] Stone tailings 63%, clay 5%, graphene 5%, calcium carbonate 5%, vermiculite 5%, high temperature co-solvent 5%, expanded graphite 3%, stabilizer 4%, debonding agent 4%, colorant 1 %.

[0040] Among them, the stone tailings are granite; the clay is yellow mud; the high-temperature flux is calcined talc; the stabilizer is yttrium oxide.

[0041] A method for preparing a foamed lightweight insulation board based on graphene and stone tailings, comprising the following steps:

[0042] S1. Raw material preparation: Weigh the materials according to the mass percentage of each raw material, mix them, and use a ball mill to mix and mill them for 10 hours until the fineness reaches 250 mesh and pass through a sieve, and finally put them into the storage bin for mixing and homogenization.

[0043] S2. Spray granulation: the raw materials pr...

Embodiment 2

[0050] A foamed lightweight insulation board based on graphene and stone tailings, made of the following components by weight percentage:

[0051] Stone tailings 68%, clay 4%, graphene 1%, calcium carbonate 5%, vermiculite 7%, high temperature co-solvent 5%, expanded graphite 3%, stabilizer 3%, debonding agent 3%, colorant 1 %.

[0052] Among them, the stone tailings are granite; the clay is yellow mud; the high-temperature flux is calcined talc; the stabilizer is yttrium oxide;

[0053] The rough product is cut into shape, and the dimensions and specifications of the foamed lightweight insulation board based on graphene and stone tailings are: length: 1200mm, width: 1200mm, thickness: 80mm.

[0054] The preparation method is the same as in Example 1.

Embodiment 3

[0056] A foamed lightweight insulation board based on graphene and stone tailings, made of the following components by weight percentage:

[0057] Stone tailings 58%, clay 7%, graphene 3%, calcium carbonate 5%, vermiculite 12%, high temperature co-solvent 5%, expanded graphite 3%, stabilizer 3%, debonding agent 3%, colorant 1 %.

[0058] Among them, the stone tailings are granite; the clay is yellow mud; the high-temperature flux is calcined talc; the stabilizer is yttrium oxide.

[0059] The rough product is cut into shape, and the dimensions and specifications of the foamed lightweight insulation board based on graphene and stone tailings are: length: 1200mm, width: 1200mm, thickness: 100mm.

[0060] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com