Aerogel foam concrete and preparation method and application thereof

A technology of foam concrete and airgel, which is applied in the field of building materials, can solve the problems of reducing structural compactness and reducing the strength of foam concrete, and achieves the effects of low dry density, strong formability, and good sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

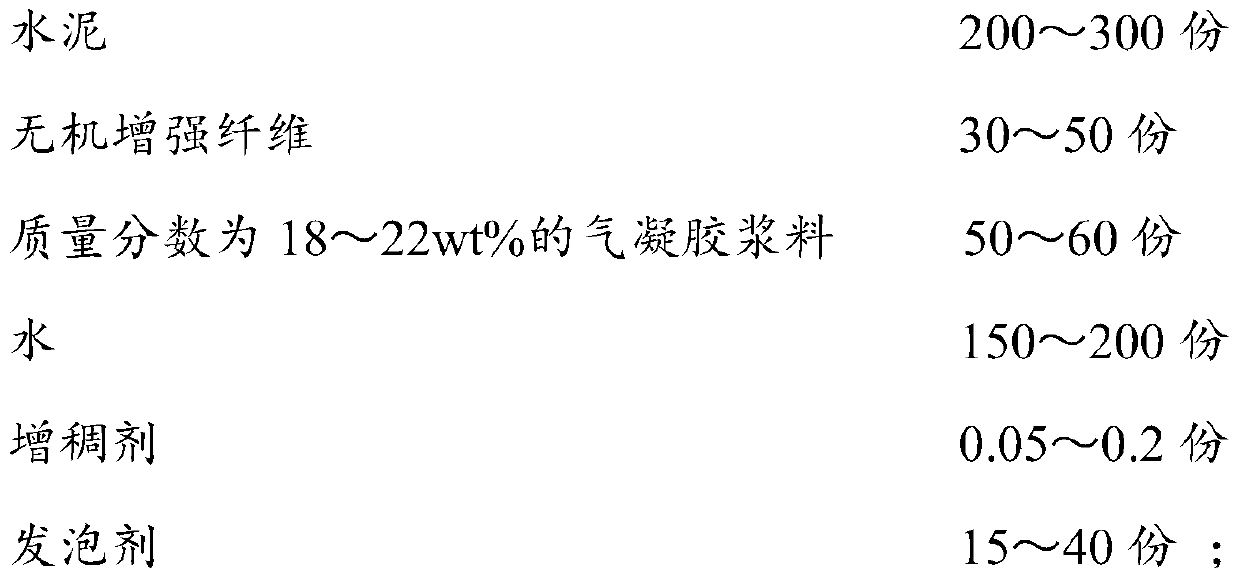

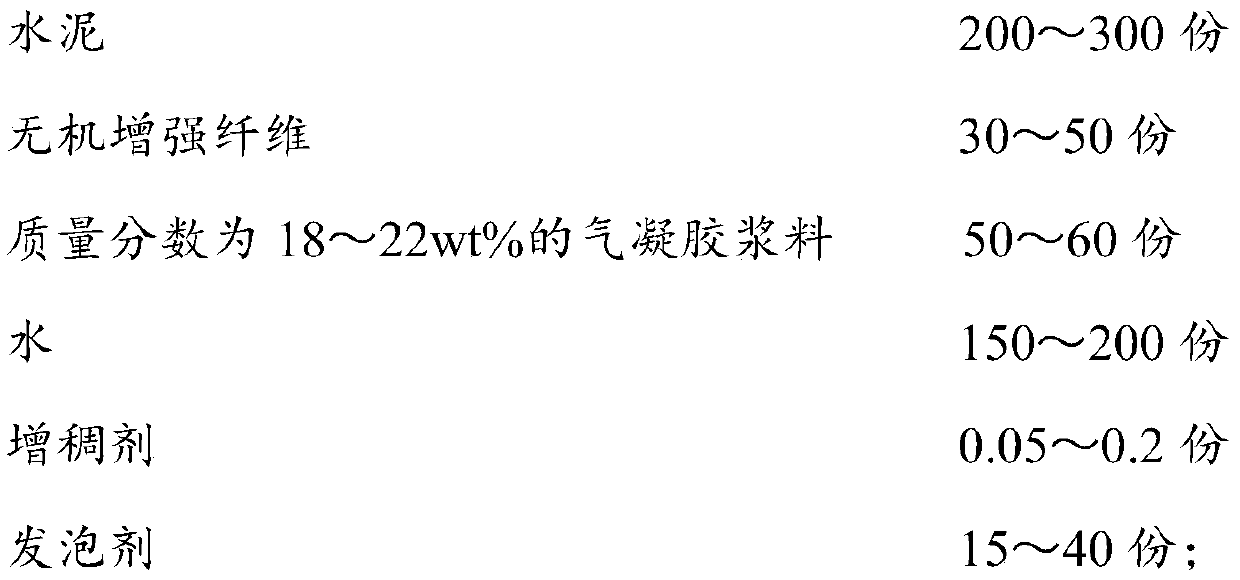

Method used

Image

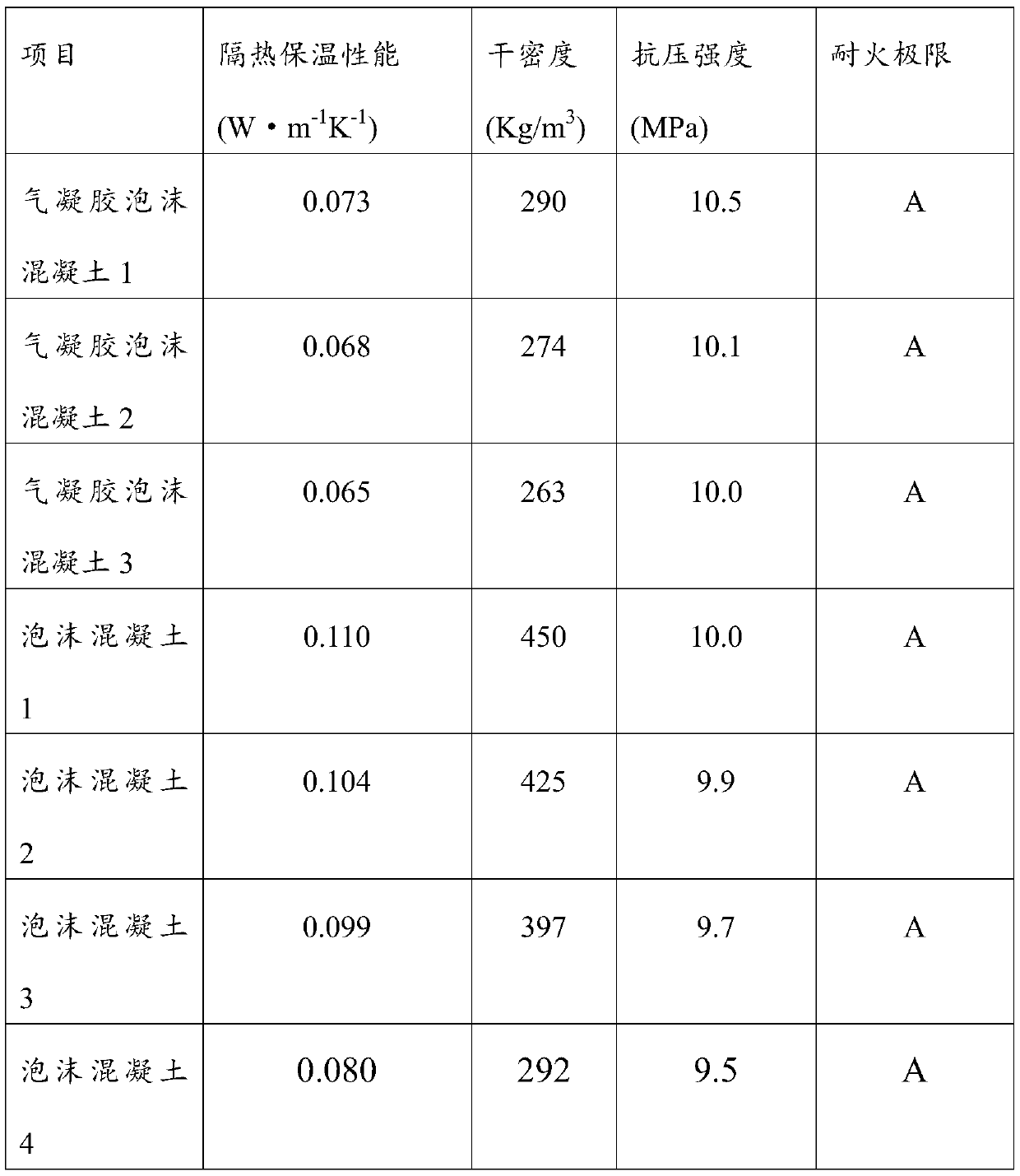

Examples

Embodiment 1

[0034] Preparation of Airgel Foam Concrete

[0035] 1) Dry-mix the cement and inorganic reinforcing fiber in the formula quantity evenly, then add part of the water in the formula quantity and mix evenly, then add the airgel slurry in the formula quantity, mix evenly, and make the cement fiber airgel slurry;

[0036] 2) Mix the remaining amount of water and foaming agent evenly to generate foam;

[0037] 3) Add the foam prepared in step 2) to the cement fiber airgel slurry prepared in step 1), stir and mix evenly to obtain a mixed slurry.

[0038] 4) Pour the mixed slurry prepared in step 3) into a mould, and then carry out mold inversion, mold removal and finished product maintenance in sequence to obtain the airgel foam concrete 1.

[0039] Among them: 200 parts of Portland cement, 30 parts of glass fiber, 50 parts of airgel slurry, the mass fraction of airgel slurry is 18%, the airgel is silica airgel, and the airgel slurry The solvent of the material is water, 150 parts ...

Embodiment 2

[0041] Preparation of Airgel Foam Concrete

[0042] 1) Dry-mix the cement and inorganic reinforcing fiber in the formula quantity evenly, then add part of the water in the formula quantity and mix evenly, then add the airgel slurry in the formula quantity, mix evenly, and make the cement fiber airgel slurry;

[0043] 2) Mix the remaining amount of water and foaming agent evenly to generate foam;

[0044] 3) Add the foam prepared in step 2) to the cement fiber airgel slurry prepared in step 1), stir and mix evenly to obtain a mixed slurry.

[0045] 4) Pour the mixed slurry prepared in step 3) into a mould, and perform inversion, demoulding, and finished product maintenance in sequence to obtain the airgel foam concrete 2.

[0046] Among them: 250 parts of ordinary Portland cement, 40 parts of ceramic fiber, 55 parts of airgel slurry, the mass fraction of airgel slurry is 20wt%, the airgel is aluminum oxide aerogel, airgel The solvent of the slurry is water. Water is 170 part...

Embodiment 3

[0049] Preparation of Airgel Foam Concrete

[0050] 1) Dry-mix the cement and inorganic reinforcing fiber in the formula quantity evenly, then add part of the water in the formula quantity and mix evenly, then add the airgel slurry in the formula quantity, mix evenly, and make the cement fiber airgel slurry;

[0051] 2) Mix the remaining amount of water and foaming agent evenly to generate foam;

[0052] 3) Add the foam prepared in step 2) to the cement fiber airgel slurry prepared in step 1), stir and mix evenly to obtain a mixed slurry.

[0053] 4) Pour the mixed slurry prepared in step 3) into a mould, and perform inversion, demoulding, and finished product maintenance in sequence to obtain the airgel foam concrete 3.

[0054] Among them: 300 parts of fly ash Portland cement, 50 parts of alumina fiber, 60 parts of airgel slurry, the mass fraction of airgel slurry is 22wt%, the airgel is titanium dioxide airgel, airgel The solvent of the slurry is water. 200 parts of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com