Thermal insulation mortar containing semidry method desulfurized fly ash and preparation method therefor

A semi-dry desulfurization and thermal insulation mortar technology is applied in the field of building materials, which can solve the problems of desulfurization ash pollution and poor stability, and achieve the effects of high fire resistance, good construction and use performance, and improved crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below:

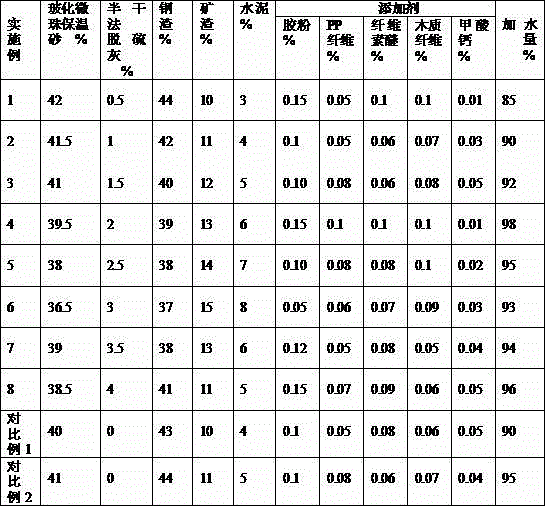

[0029] Table 1 is the raw material value list of each embodiment of the present invention and comparative examples;

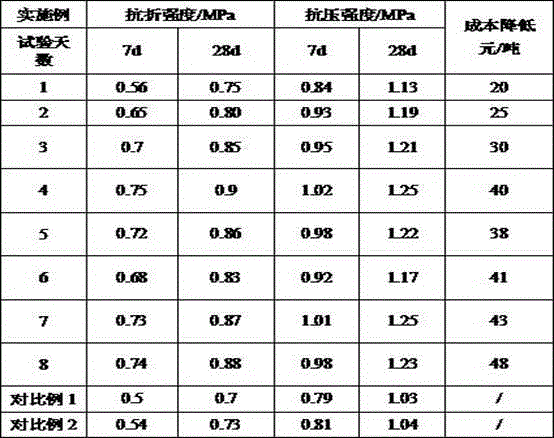

[0030] Table 2 is a list of the mechanical properties of the various embodiments of the present invention and comparative examples.

[0031] Each embodiment of the present invention is produced according to the following steps:

[0032] 1) Dry the semi-dry desulfurization ash and steel slag, and control the water content by weight to no more than 1%;

[0033] 2) Crushing semi-dry desulfurization ash and steel slag, the particle size of semi-dry desulfurization ash is controlled at 2 / kg;

[0034] 3) Fully mix the semi-dry desulfurization ash, steel slag, cement, slag and additives;

[0035] 4) Add water, and add according to 85~100% per kilogram of vitrified microbead insulation sand, and stir evenly;

[0036] 5) Add vitrified bead insulation sand and stir evenly;

[0037] 6) Packaging, ready to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com