Fungal hypha composite thermal insulation board and preparation method thereof

A composite thermal insulation and mycelium technology, applied in fungi and other directions, can solve the problems of unsatisfactory water-repellent treatment effect of pearlescent sand, increased bulk density of pearlescent sand, unsatisfactory thermal insulation performance, etc., to achieve excellent thermal insulation effect, excellent thermal insulation anti-cracking, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

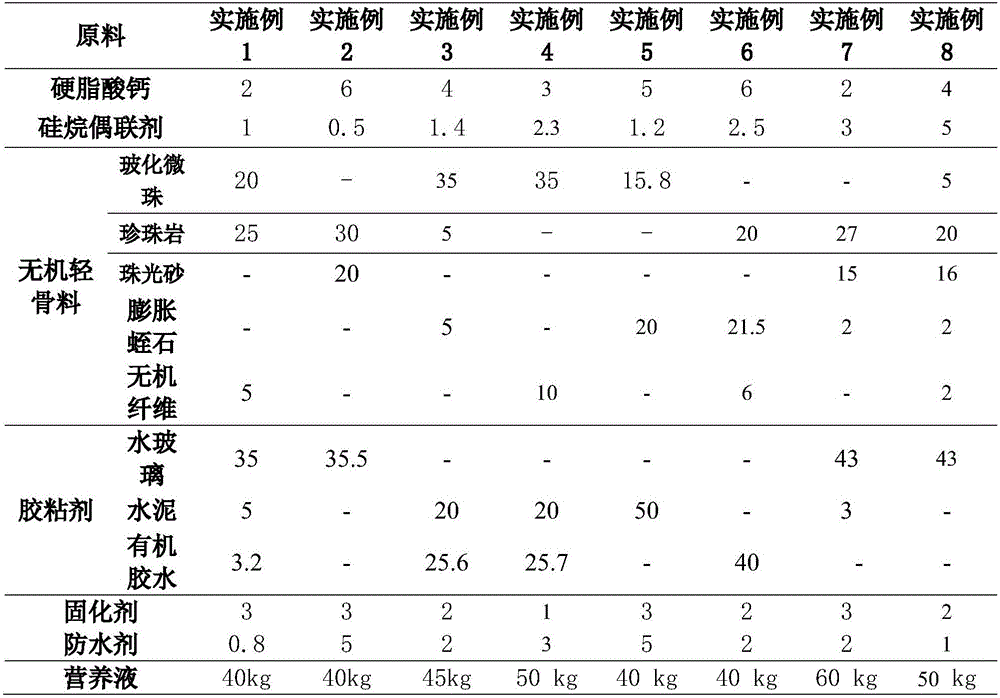

[0030] A kind of fungal mycelia composite insulation board, its raw material formula is shown in Table 2, and its preparation method is as follows:

[0031] 1. According to the formula in Table 2, the inorganic lightweight aggregate and the nutrient solution are mixed evenly to make a culture medium, and the culture medium is autoclaved (the sterilization method adopts conventional technology) to inoculate mycelia, and the inoculation amount of mycelia is 10 %, after the inoculation is completed, the mycelium is cultivated, the growth conditions of the mycelium are controlled, and the mycelium mixture is obtained after the mycelium is filled with the culture medium;

[0032] 2. Pre-mix the mycelium mixture with calcium stearate (powder) for 2-5 minutes, so that the calcium stearate powder is evenly coated on the surface pores of the inorganic lightweight aggregate and mycelium, and then mixed evenly Add curing agent (embodiment 1-5 is silicon phosphate, embodiment 6-8 is sodiu...

Embodiment 9

[0039] The specific preparation method of the insulation board of this embodiment is the same as that of Embodiment 1, the difference is that the composition (parts by weight) of the inorganic lightweight aggregate is: SiO 2 Airgel 80 parts, expandable graphite 12 parts, glass microspheres 20 parts, expanded perlite 40 parts, calcium silicate fiber 15 parts.

Embodiment 10

[0041] The specific preparation method of the insulation board of this embodiment is the same as that of Embodiment 1, the difference is that the composition (parts by weight) of the inorganic lightweight aggregate is: SiO 2 40 parts of airgel, 5 parts of expandable graphite, 10 parts of glass microspheres, 40 parts of expanded perlite, and 20 parts of calcium silicate fiber.

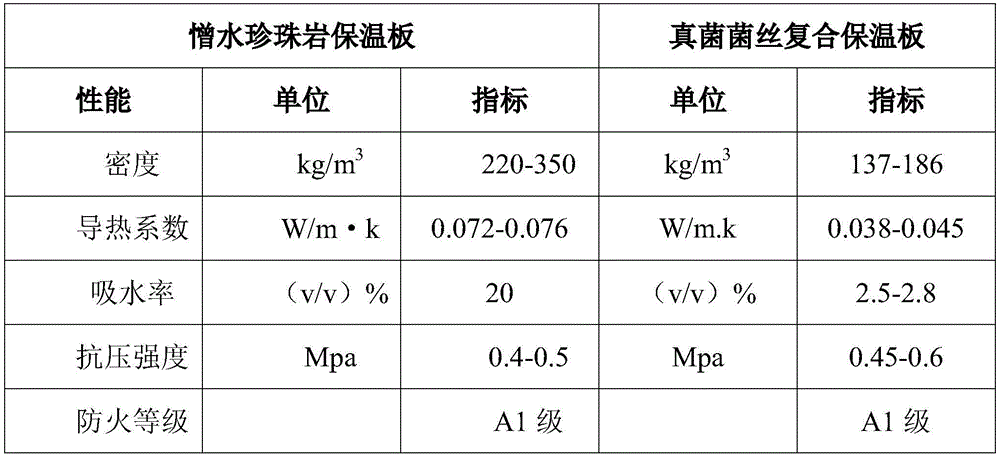

[0042] After testing, the performance of the fungal mycelium composite insulation board prepared in the above examples is compared with that of the existing hydrophobic perlite insulation board, and the data are shown in Table 2.

[0043] Table 2 Comparison of performance indicators between hydrophobic perlite insulation board and fungal mycelium composite insulation board

[0044]

[0045] It has been verified that the thermal conductivity of the product of the invention is low, and the thin fiber tube improves the compressive and flexural strength of the product. Examples 9 and 10 have better comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com