Desulfurized-gypsum-base lightweight spraying gypsum mortar

A technology for desulfurized gypsum and gypsum mortar, which is applied in the fields of comprehensive utilization of solid waste and building materials, can solve the problems of high thermal conductivity that cannot meet the requirements of building energy-saving development, large capacity of cement plastering mortar, and reduced indoor use area, etc. The effect of improving pumpability and sprayability, high ergonomics, and improved operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

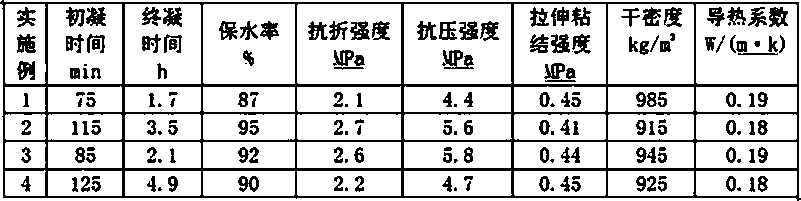

Examples

Embodiment 1

[0031] A desulfurized gypsum-based lightweight spraying gypsum mortar, which consists of the following components in parts by weight: 50 parts of desulfurized gypsum, 30 parts of construction sand with a particle size of 30-50 mesh, and vitrified microbeads with a particle size of 50-70 mesh 3 Parts, 16 parts of stone powder, 0.1 part of sodium citrate retarder, 0.1 part of hydroxypropyl methylcellulose ether with a viscosity of 60,000, 0.04 part of sodium alkylbenzenesulfonate air-entraining agent, 0.05 part of starch ether, wherein, The desulfurization gypsum is hemihydrate gypsum obtained by calcining waste residue produced after flue gas desulfurization.

Embodiment 2

[0033] A desulfurized gypsum-based lightweight spraying gypsum mortar, which consists of the following components in parts by weight: 65 parts of desulfurized gypsum, 20 parts of construction sand with a particle size of 30-50 mesh, and vitrified microbeads with a particle size of 50-70 mesh 5 10 parts of stone powder, 0.5 part of sodium tripolyphosphate retarder, 0.3 part of hydroxyethyl methyl cellulose ether with a viscosity of 30,000, 0.02 part of sodium alkylaryl sulfonate air-entraining agent, 0.1 part of starch ether, Wherein, the desulfurization gypsum is hemihydrate gypsum obtained by calcining waste residue produced after flue gas desulfurization.

Embodiment 3

[0035] A desulfurized gypsum-based lightweight spraying gypsum mortar, which consists of the following components in parts by weight: 50 parts of desulfurized gypsum, 25 parts of construction sand with a particle size of 30-50 mesh, and vitrified microbeads with a particle size of 50-70 mesh 4 parts, 20 parts of stone powder, 0.2 parts of sodium hexametaphosphate retarder, 0.2 parts of hydroxypropyl methylcellulose ether with a viscosity of 40,000, 0.025 parts of sodium alkylbenzenesulfonate air-entraining agent, and 0.07 parts of starch ether, of which , the desulfurization gypsum is hemihydrate gypsum obtained by calcining the waste residue produced after flue gas desulfurization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com