Gypsum-based composite lightweight thermal-insulation mortar and preparation method thereof

A thermal insulation mortar and gypsum-based technology, which is applied in the field of building materials, can solve the problems of uneven heating of the ground surface of geothermal heating, increase the load of the ground and floor, and the proportion of thermal insulation materials, etc. effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

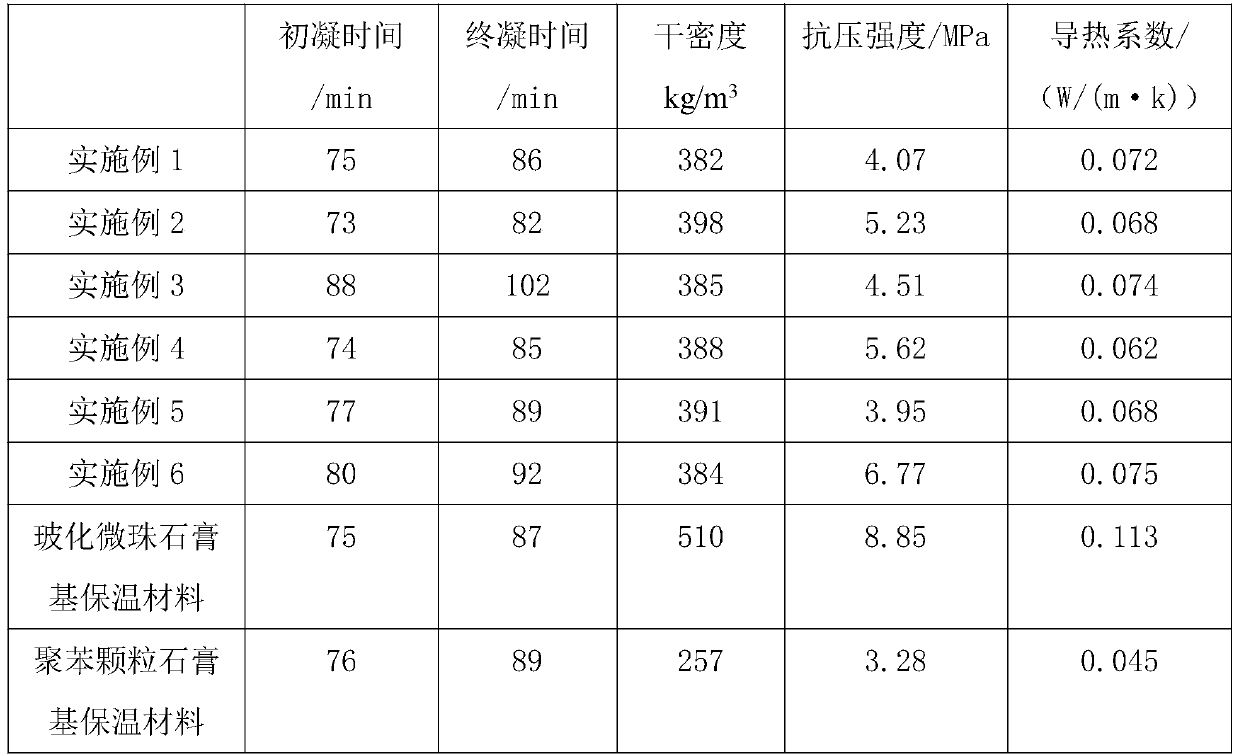

Examples

Embodiment 1

[0021] A gypsum-based composite lightweight thermal insulation mortar, which includes the following components by weight: gypsum powder (β-hemihydrate gypsum powder, specific surface area is 340m 2 / kg) 70 parts, polystyrene particles (average particle size 3-5mm, bulk density 11-15kg / m 3 ) 1.5 parts, vitrified microbeads (0.2-0.3mm, bulk density 170-190kg / m 3 ) 11 parts, cement (PⅡ52.5 cement) 7 parts, redispersible latex powder (Wacker 6020N vinyl acetate-ethylene copolymer) 1.5 parts, water retaining agent (hydroxypropyl methylcellulose ether, viscosity is 80000mpa.s) 0.45 parts, gypsum retarder (vegetable protein plaster retarder) 0.4 parts, PC - 0.5 parts of 1016 type polycarboxylate powder superplasticizer, 0.5 parts of polypropylene fiber (length <10mm, aspect ratio 10-50:1), 65 parts of water.

[0022] The preparation method of gypsum-based composite lightweight thermal insulation mortar: put gypsum powder, cement, redispersible latex powder, water retaining agent, ...

Embodiment 2

[0024] A gypsum-based composite lightweight thermal insulation mortar, which includes the following components by weight: gypsum powder (β-hemihydrate gypsum powder, specific surface area is 340m 2 / kg) 69 parts, polyphenylene particles (average particle size 3-5mm, bulk density 11-15kg / m 3 ) 1.6 parts, vitrified microbeads (0.2-0.3mm, bulk density 170-190kg / m 3 ) 12 parts, cement (PⅡ52.5 cement) 7 parts, redispersible latex powder (Wacker 6020N vinyl acetate-ethylene copolymer) 1.6 parts, water retaining agent (hydroxypropyl methylcellulose ether, viscosity is 80000mpa.s) 0.48 parts, gypsum retarder (vegetable protein plaster retarder) 0.4 parts, HY 0.54 parts of polycarboxylate powder superplasticizer, 0.5 parts of polypropylene fiber (length <10mm, aspect ratio 10-50:1), and 68 parts of water.

[0025] The preparation method of gypsum-based composite lightweight thermal insulation mortar: put gypsum powder, cement, redispersible latex powder, water retaining agent, gypsu...

Embodiment 3

[0027] A gypsum-based composite lightweight thermal insulation mortar, which includes the following components by weight: gypsum powder (β-hemihydrate gypsum powder, specific surface area is 340m 2 / kg) 72 parts, polyphenylene particles (average particle size 3-5mm, bulk density 11-15kg / m 3 ) 1.5 parts, vitrified microbeads (0.2-0.3mm, bulk density 170-190kg / m 3 ) 11 parts, cement (PⅡ52.5 cement) 7.1 parts, redispersible latex powder (Wacker 6020N vinyl acetate-ethylene copolymer) 1.56 parts, water retaining agent (hydroxypropyl methylcellulose ether, viscosity is 100000mpa.s) 0.5 parts, gypsum retarder (citric acid) 0.25 parts, PC-1016 polycarboxylate 0.46 parts of acid powder water reducer, 0.51 parts of polypropylene fiber (length <10mm, aspect ratio 10-50:1), 66 parts of water.

[0028] The preparation method of gypsum-based composite lightweight thermal insulation mortar: put gypsum powder, cement, redispersible latex powder, water retaining agent, gypsum retarder, wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com