Smoke-suppressing type outdoor flame retardant steel structure fireproof coating

A technology for fire retardant coatings and steel structures, applied in the field of fire retardant coatings, can solve problems such as harm to human health, high engineering cost, affecting construction speed, etc., and achieve the effects of good flame retardant performance, improved fire resistance limit, and improved fire performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

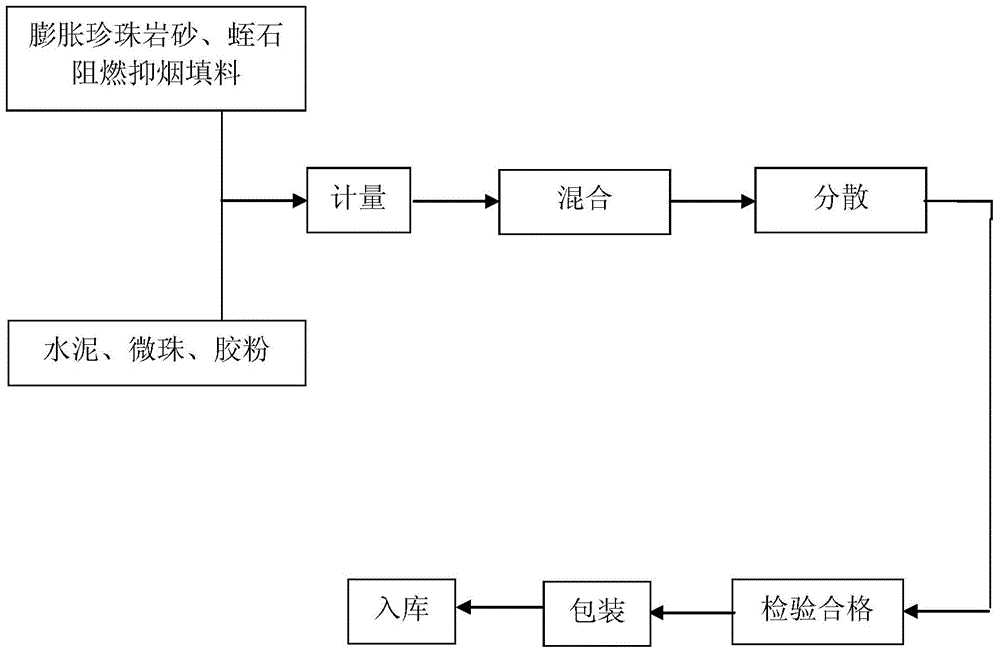

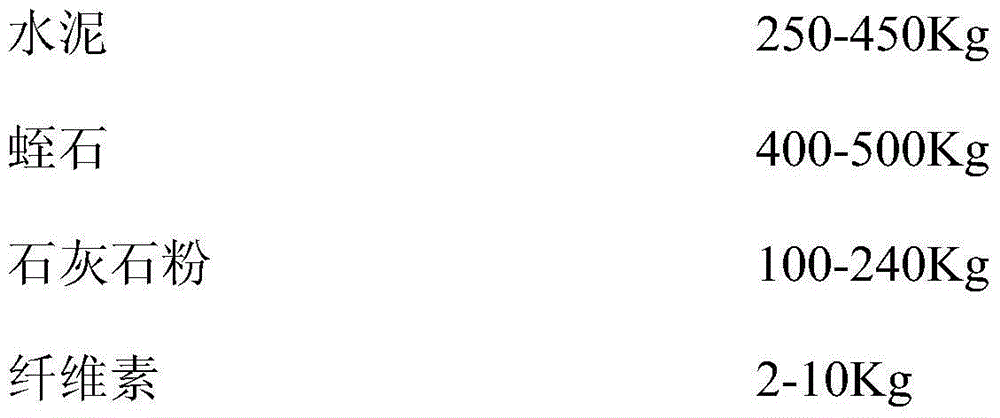

[0037] according to figure 1 Shown technological process, the powder component of making, wherein every ton of powder component contains the powder of listed weight in Table 1.

[0038]

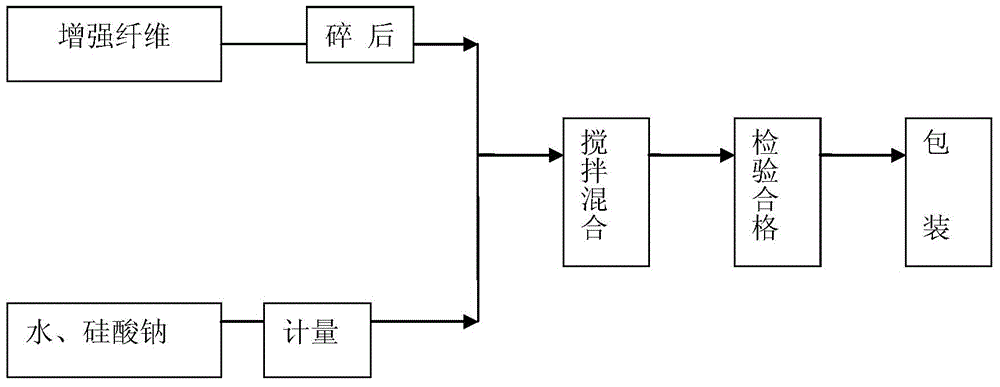

[0039] according to figure 2 The process flow shown makes the sizing material component, wherein every ton of the sizing material component contains the sizing material and water of the weight listed in Table 2.

[0040] Compound name

Weight (Kg)

980

[0041] By mixing the rubber component and the powder component in a ratio of 1:1, the smoke-suppressing outdoor flame-retardant steel structure fireproof coating of the present invention can be obtained, which can be directly painted when used.

[0042] Samples were prepared with an existing steel structure fireproof coating formula, and the powder was prepared as follows:

[0043] Powder name

cement

limestone powder

Flame retardant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com