Low-density aerated concrete product and preparation method thereof

An air-entrained concrete, low-density technology, applied in the field of building materials, can solve the problems of hidden dangers of the environment and safety, low comprehensive utilization rate of output, etc., and achieve the effects of reducing the breakage rate, improving the appearance quality, and improving the pouring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

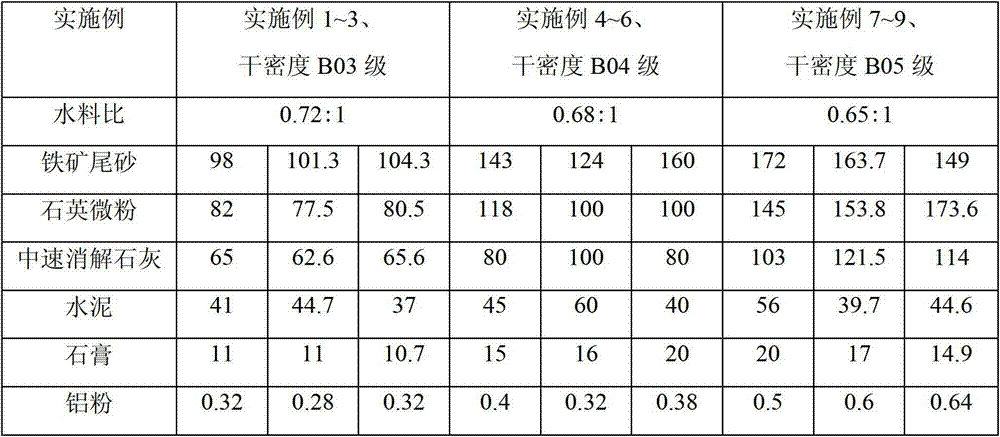

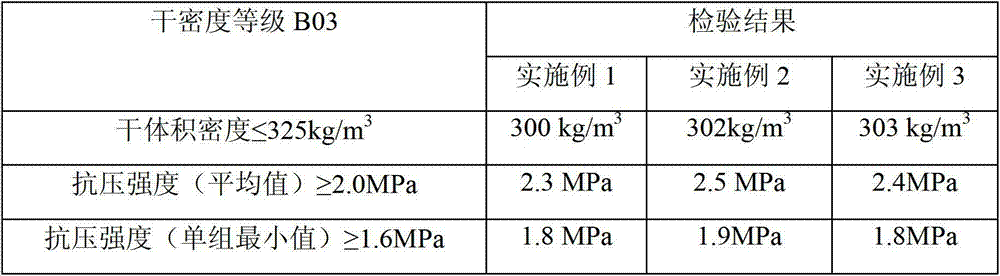

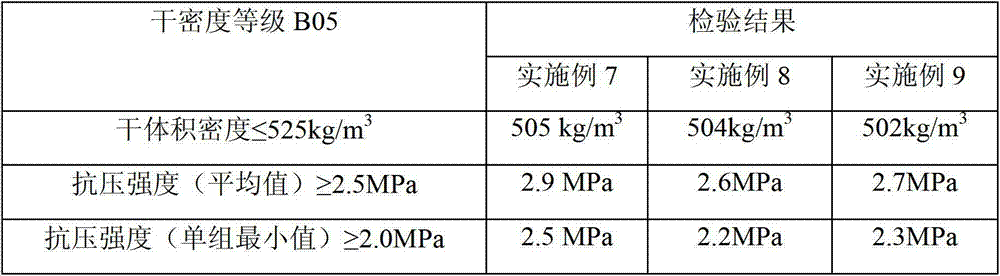

[0024] A low-density air-entrained concrete product and its preparation method of the present invention will be further described through specific examples below, wherein Example 1 is the best example.

[0025] (1) Use the raw materials in parts by weight described in the examples in Table 1, wherein the lime is medium-speed digested lime, the effective CaO content is not less than 75%, MgO<5%, the digestion time is 10-15min, and the digestion temperature is 65-80°C , after being crushed, it is stored in the cylinder warehouse, and then enters the ball mill for grinding and then it is used for later use. Cement is stored in the batching silo for later use. Lime and cement are sent to the electronic weighing scale by the feeder for measurement. Iron tailings, quartz micropowder and gypsum are mixed with appropriate amount of water to make the fineness of the materials reach 8% of 200 mesh sieve, 12% of 200 mesh sieve and 4% of 200 mesh sieve respectively. The slurry is pumped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com