Heat insulating type pipeline fixing support

A pipeline fixing and adiabatic technology, applied in the direction of pipeline support, pipeline protection through thermal insulation, pipeline protection, etc., can solve the problem of reducing the heat transfer efficiency of the heat network, achieve good thermal insulation effect, stable radial matching position, avoid Effects of detachment or misplacement shelving accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

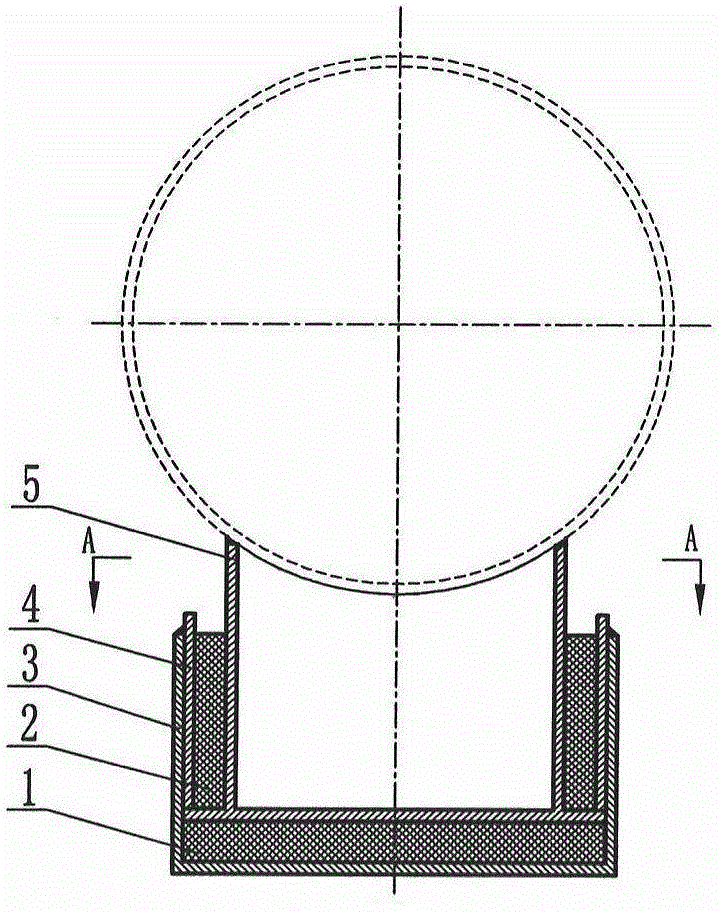

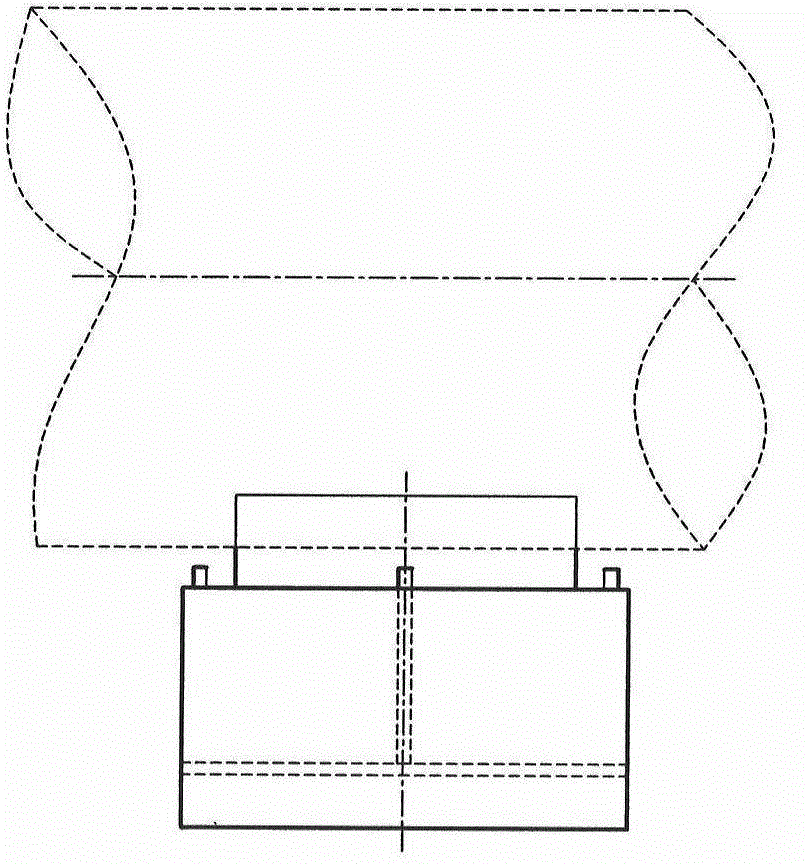

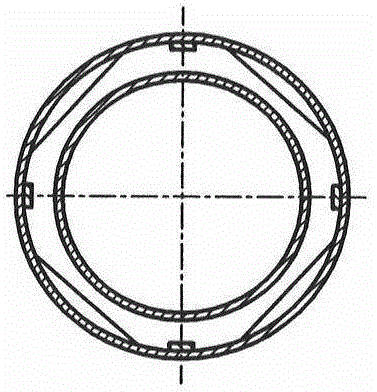

[0015] figure 1 The shown insulating pipe fixing bracket is installed in the branch pipeline of the industrial heating network. In this embodiment, the supported pipe 6 has a diameter of 630mm, and the temperature of the medium to be transmitted is 327°C. The heat-insulating pipe fixing bracket matching the pipe 6 includes a bottom lining 1 , a wall lining 2 , an outer cylinder 3 , a column pile 4 and an inner cylinder 5 . Both the outer cylinder body 3 and the inner cylinder body 5 are bottomed open cylinders, and the upward opening of the inner cylinder body 5 is fixedly connected with the outer wall of the supported pipe 6 . In order to achieve high-efficiency thermal insulation between the bottom surface of the outer cylinder 3 and the bottom surface of the inner cylinder 5, in this embodiment, a 60mm thick underlayment 1 is laid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com