Dry-mixed composite light aggregate concrete based on inorganically modified polyurethane particles

A technology of lightweight aggregate concrete and polyurethane particles, applied in the field of thermal insulation lightweight aggregate concrete, can solve problems such as potential safety hazards, achieve the effect of ensuring strength, standardizing concrete density grade, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

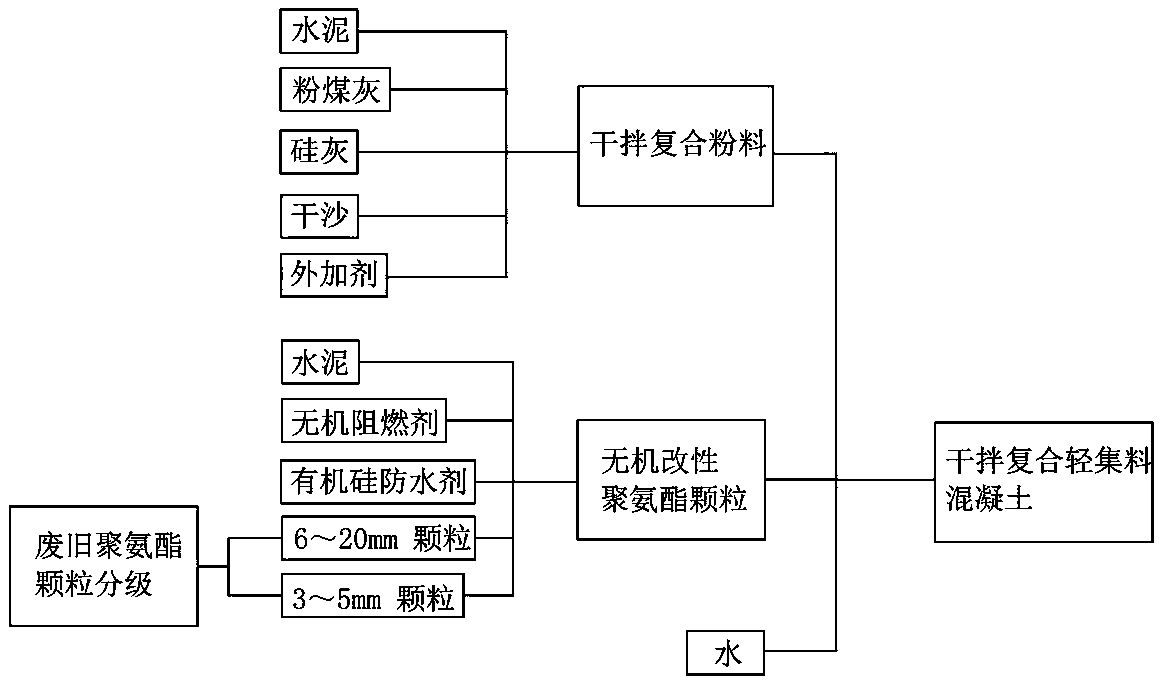

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Preparation of dry-mixed composite lightweight aggregate concrete with a density grade of 600 based on inorganic modified polyurethane particles

[0040] Step 1: Carry out particle size classification on waste polyurethane particles to obtain waste polyurethane particles with two particle sizes of 3-5 mm and 6-20 mm.

[0041] Step 2: Inorganic modification treatment is carried out on the waste polyurethane particles with two particle sizes described in step 1 to obtain inorganic modified polyurethane particles.

[0042] The inorganic modification treatment is: use 1.5 parts by weight of silicone water repellent to atomize and waterproof 25 parts by weight of waste polyurethane particles to obtain waterproof polyurethane particles with wet surface, and then add 3.5 parts by weight of magnesium hydroxide and 8 parts by weight of cement The waterproof polyurethane particles are surface wrapped to obtain modified polyurethane particles with a dense protective laye...

Embodiment 2

[0046] Example 2 Preparation of dry-mixed composite lightweight aggregate concrete with a density grade of 800 based on inorganic modified polyurethane particles

[0047] Step 1: Carry out particle size classification on waste polyurethane particles to obtain waste polyurethane particles with two particle sizes of 3-5 mm and 6-20 mm.

[0048] Step 2: Inorganic modification treatment is carried out on the waste polyurethane particles with two particle sizes described in step 1 to obtain modified polyurethane particles with a dense protective layer of inorganic materials on the surface.

[0049] The inorganic modification treatment is as follows: 55 parts by weight of waste polyurethane particles are atomized and waterproofed with 7 parts by weight of organosilicon waterproofing agent to obtain waterproof polyurethane particles with wet surface, and then 11 parts by weight of ammonium polyphosphate and 62 parts by weight of cement are added The waterproof polyurethane particles ...

Embodiment 3

[0053] Example 3 Preparation of dry-mixed composite lightweight aggregate concrete with a density grade of 1000 based on inorganic modified polyurethane particles

[0054] Step 1: Carry out particle size classification on waste polyurethane particles to obtain waste polyurethane particles with two particle sizes of 3-5mm and 6-21mm.

[0055] Step 2: Inorganic modification treatment is carried out on the waste polyurethane particles with two particle sizes described in step 1 to obtain inorganic modified polyurethane particles.

[0056] The inorganic modification treatment is as follows: 4 parts by weight of silicone water repellent is used to atomize and waterproof 40 parts by weight of waste polyurethane particles to obtain waterproof polyurethane particles with wet surface, and then add 7 parts by weight of ammonium polyphosphate and 35 parts by weight of cement The waterproof polyurethane particles are surface wrapped to obtain modified polyurethane particles with a dense p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com