Inorganic calcium sulfate whisker heat retaining panel and preparation method thereof

A technology of calcium sulfate whisker and thermal insulation board is applied in the field of building material manufacturing, which can solve the problems of high water absorption, poor machining performance, flammability, etc., and achieve the effects of low dry density, low construction cost, and overcoming flammability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the preparation method of the inorganic calcium sulfate whisker insulation board that the present embodiment provides, it comprises the steps:

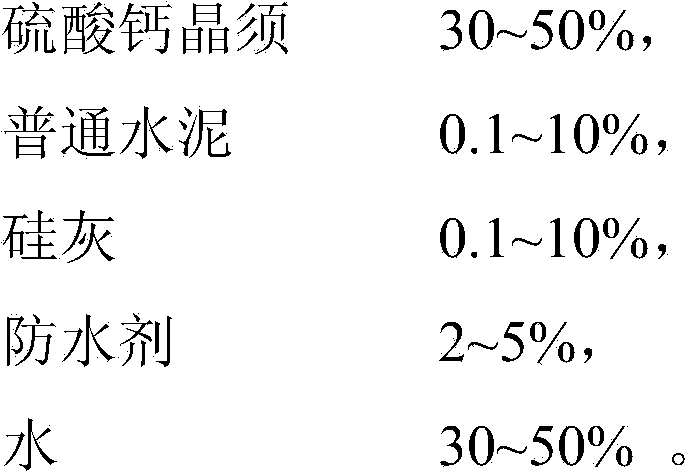

[0028] (1) Prepare raw materials: each component of the raw material and its weight percentage are as follows:

[0029]

[0030] (2) Take by weighing 900g of calcium sulfate whiskers, 20g of ordinary cement, and 10g of silica fume, put them into a mixing tank, stir and mix evenly, and obtain a dry mix;

[0031] (3) Weigh 100g waterproofing agent and add it to 970g water, stir and mix evenly, join in the above-mentioned dry mix, continue to stir evenly, obtain slurry;

[0032] (4) Pour the slurry into a mold of 90cm * 90cm * 10cm, leave it at room temperature for molding, and demould to obtain a wet billet;

[0033] (5) The wet billet was dried in a blast drying oven at 100°C for 20 hours, calcined at 250°C for 2 hours and at 500°C for 2 hours in a program-controlled high-temperature calciner to obtain an inorg...

Embodiment 2

[0036] The inorganic calcium sulfate whisker insulation board provided in this embodiment and its preparation method are basically the same as in Example 1, except that:

[0037] A kind of preparation method of inorganic calcium sulfate whisker insulation board, it comprises the steps:

[0038] (1) Prepare raw materials: each component of the raw material and its weight percentage are as follows:

[0039]

[0040] (2) Take by weighing 1000g of calcium sulfate whiskers, 10g of ordinary cement, and 10g of silica fume, put them into a mixing tank, stir and mix evenly, and obtain a dry mix;

[0041] (3) Weigh 80g waterproofing agent and add it to 900g water, stir and mix evenly, join in the above-mentioned dry mix, continue to stir evenly, obtain slurry;

[0042] (4) Pour the slurry into a mold of 90cm * 90cm * 10cm, leave it at room temperature for molding, and demould to obtain a wet billet;

[0043] (5) The wet billet was dried in a blast drying oven at 100°C for 15 hours,...

Embodiment 3

[0046] The inorganic calcium sulfate whisker insulation board provided in this embodiment and its preparation method are basically the same as those in Embodiments 1 and 2, except that:

[0047] A kind of preparation method of inorganic calcium sulfate whisker insulation board, it comprises the steps:

[0048] (1) Prepare raw materials: each component of the raw material and its weight percentage are as follows:

[0049]

[0050] (2) Take by weighing 800g of calcium sulfate whiskers, 200g of ordinary cement, and 100g of silica fume, put them into a mixing tank, stir and mix evenly, and obtain a dry mix;

[0051] (3) Take 60g waterproofing agent and join in 840g water, stir and mix evenly, join in the above-mentioned dry mix, continue to stir evenly, obtain slurry;

[0052] (4) Pour the slurry into a mold of 90cm * 90cm * 10cm, leave it at room temperature for molding, and demould to obtain a wet billet;

[0053] (5) The wet billet was dried in a blast drying oven at 110°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com