Bipolar resistive access memory and preparation method thereof

A technology of resistive memory and devices, which is applied in the field of resistive memory and its preparation, and can solve problems such as the performance difference of RRAM devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

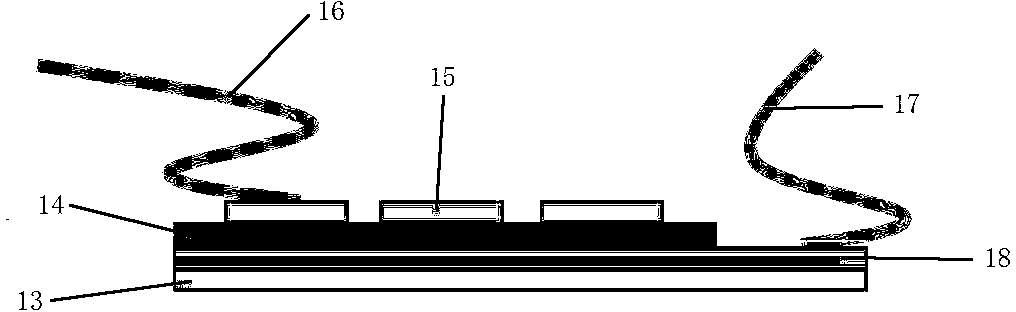

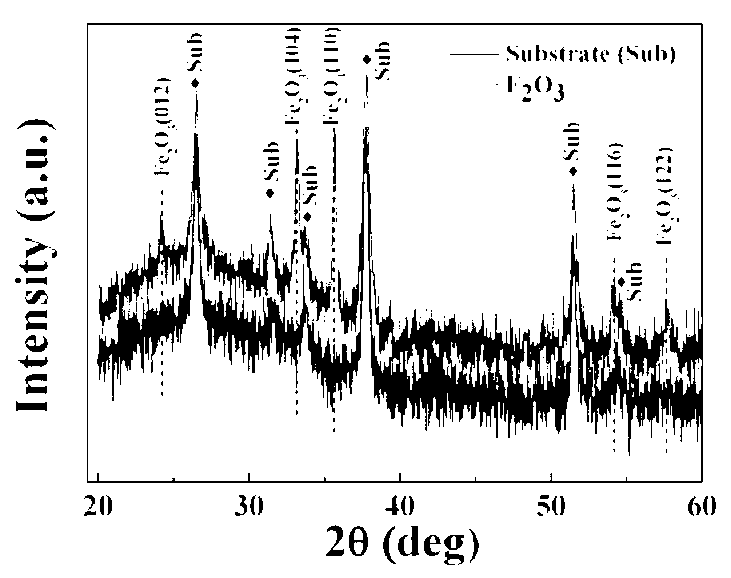

[0030] Example 1 Preparation of Au / ɑ-Fe 2 o 3 / FTO bipolar resistive memory device

[0031] Such as Figure 5 As shown, the preparation of α-Fe 2 o 3 The devices used for the film include: ultrasonic oscillator 1, container 2, compressed air machine 3, compressed gas control valve 4, atomizing gas control valve 5, heating device 8, and reaction furnace 9. The container 2 where the precursor liquid is placed is provided with input and output pipelines, a compressed gas control valve 4 is provided in the input pipeline, an atomized gas control valve 5 is provided on the output pipeline, and a spraying gas is provided at the port of the output pipeline. The nozzle 10 and the spray nozzle 10 are placed in the reaction furnace 9, the reaction furnace 9 is provided with a thermocouple heating device 8, the thermocouple heating device 8 is provided with a substrate table 7 for placing an insulating bottom liner, and above the reaction furnace 9 is a Vent 11.

[0032] Specific pre...

Embodiment 2

[0041] Example 2Au / ɑ-Fe 2 o 3 / FTO bipolar resistive memory device

[0042] Common containers, atomizing devices, air compressors, reaction furnaces, heating devices and spraying devices are used.

[0043] Specific preparation method:

[0044] a. Preparation of precursor solution: Dissolve iron acetylacetonate in absolute ethanol to prepare a 0.5mol / L solution as a precursor solution;

[0045] b. Place the silicon chip base substrate sprayed with fluorine-doped tin oxide film on the heating device in the reaction furnace, and heat it until the temperature in the reaction furnace rises to 350-450 ° C;

[0046] c. Place the precursor liquid in a container and atomize it through an ultrasonic atomization device. The atomized gas is transported to the reaction furnace under the action of compressed air, and sprayed onto the heated fluorine-doped tin oxide film through a nozzle, and deposited on The thickness is 30nm~100nm, forming ɑ-Fe 2 o 3 Film; the flow rate of the compre...

Embodiment 3

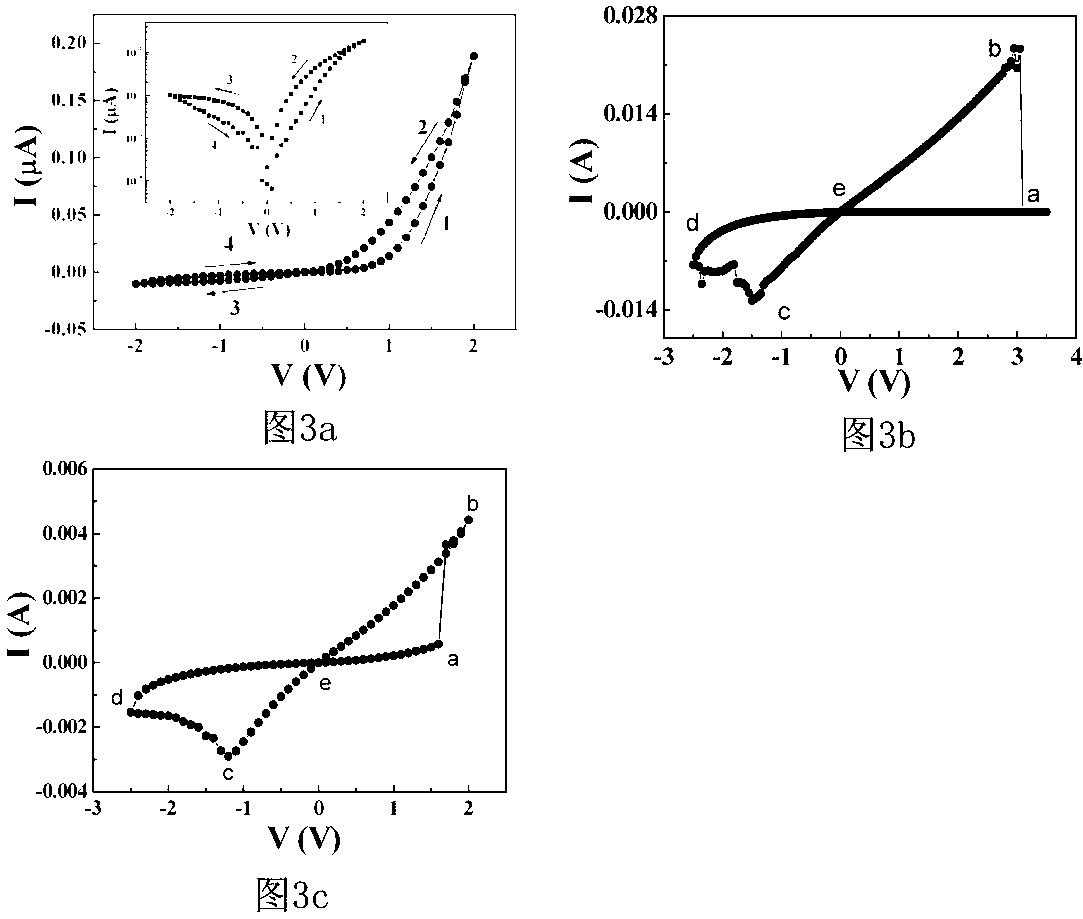

[0050] Embodiment 3 tests the performance of the device prepared in embodiment 1

[0051] Test instrument: Keithley4200 source test unit.

[0052] Test items: the voltage-current characteristics of the device, as well as the basic function, fatigue resistance and retention characteristics of the device.

[0053] Test Results:

[0054] (1) The resistive switching characteristics of the storage device prepared in the present invention.

[0055] The present invention uses ɑ-Fe 2 o 3 The material is used as a resistive switch material, and the film is sandwiched between the fluorine-doped tin oxide lower electrode film and the gold (or platinum, copper) upper electrode film to form a micro-sandwich structure memory unit. When a scanning voltage higher than a certain threshold is applied on the upper electrode (the scanning voltage direction is 0→+Vmax→-Vmax→0), a certain window appears in the I-V curve of the device, showing the main characteristics of the resistive switching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com