Cerium-antimony codoped tin oxide thin film, powder and preparation method thereof

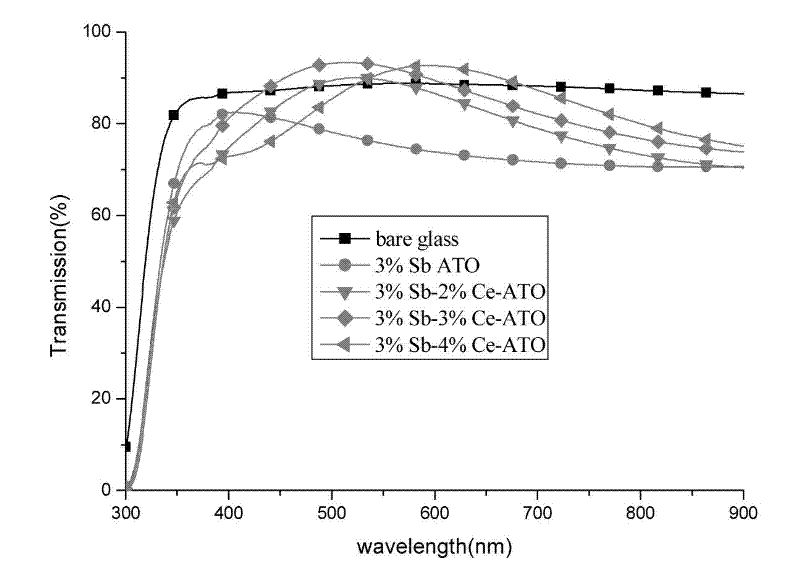

A technology of co-doping and tin oxide, applied in the direction of coating, etc., can solve the problem of weakening visible light transmittance, etc., and achieve the effect of increased transmittance, low cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 112.81g SnCl 2 2H 2 O (0.5mol) was dissolved in 1200ml of absolute ethanol, stirred and refluxed at 76°C for 2h; then weighed 1.14g of SbCl 3 (0.005mol) and 2.17g Ce(NO 3 ) 3 ·6H 2 O (0.005mol) was dissolved in 200ml of absolute ethanol respectively, heated and stirred to dissolve; SbCl 3 and Ce(NO 3 ) 3 ·6H 2 The ethanol solution of O was simultaneously added dropwise to the SnCl 2 In the ethanol solution, continue to stir and reflux at 80 ° C for 4 hours; leave it in the air for 24 hours to obtain cerium-antimony co-doped stannous chloride sol.

[0036] The obtained cerium-antimony co-doped tin chloride sol was fired in a high-temperature oven at 600° C. for 5 hours, and ball milled to obtain cerium-antimony co-doped tin oxide powder.

[0037] The obtained cerium-antimony co-doped stannous chloride sol was formed into a film on glass by dipping method, and then baked and cured in a high-temperature oven at 600°C for 5 hours to obtain a cerium-antimony c...

Embodiment 2

[0040] Weigh 112.81g SnCl 2 2H 2 O (0.5mol) was dissolved in 1200ml ethylene glycol, stirred and refluxed at 76°C for 2h; then weighed 2.28g SbCl3 (0.01mol) and 3.17g of cerium acetate (0.01mol) were respectively dissolved in 200ml of absolute ethanol, heated and stirred to dissolve it; SbCl 3 Add the ethanol solution of cerium acetate dropwise to SnCl 2 In the ethanol solution, continue to reflux and stir at 80°C for 4h; leave it to age in the air for 48h, and obtain the cerium-antimony co-doped stannous chloride sol.

[0041] The obtained cerium-antimony co-doped tin chloride sol was fired in a high-temperature oven at 700° C. for 2 hours, and ball milled to obtain cerium-antimony co-doped tin oxide powder.

[0042] The obtained cerium-antimony co-doped stannous chloride sol was formed into a film on glass by dipping method, and then baked and cured in a high-temperature oven at 700°C for 2 hours to obtain a cerium-antimony co-doped tin oxide film with a film thickness of ...

Embodiment 3

[0045] Weigh 112.81g SnCl 2 2H 2 O (0.5mol) was dissolved in 1200ml ethylene glycol monomethyl ether, stirred at 76°C for 2h; then weighed 3.42g SbCl 3 (0.015mol) and 5.85g cerium chloride (0.015mol) were dissolved in 200ml absolute ethanol respectively, heated and stirred to make it dissolve; SbCl 3 And the ethanol solution of cerium chloride was added dropwise to SnCl 2 In the ethylene glycol monomethyl ether solution, continue to reflux and stir at 90 ° C for 2 h; leave it to age in the air for 36 h, and obtain the cerium-antimony co-doped stannous chloride sol.

[0046] The obtained cerium-antimony co-doped tin chloride sol was fired in a high-temperature oven at 800° C. for 2 hours, and ball milled to obtain cerium-antimony co-doped tin oxide powder.

[0047] The obtained cerium-antimony co-doped stannous chloride sol was formed into a film on glass by dipping and pulling method, and then baked and cured in a high-temperature oven at 800°C for 2 hours to obtain a ceriu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com