Lithium ion battery negative electrode and preparation method thereof

A lithium ion battery and negative electrode technology, applied in the field of lithium ion battery negative electrode and its preparation, can solve the problems of traditional lithium ion battery application limitations, large thickness expansion rate, short cycle life, etc., to achieve improved polarization effect and low gram capacity , good magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

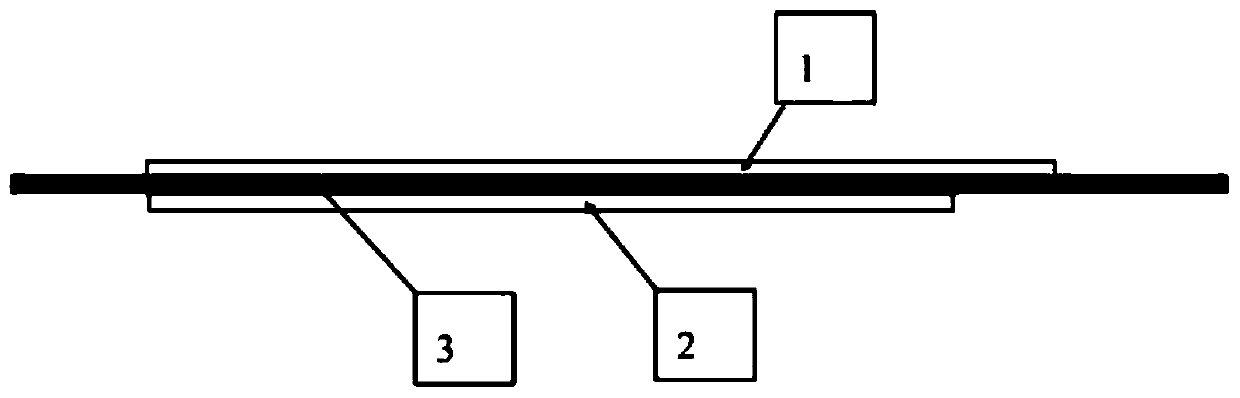

[0026] A lithium-ion battery negative electrode, comprising a negative electrode collector 3 and a negative electrode coating, the negative electrode coating includes a coating I1 and a coating II2, the coating I1 is coated on one surface of the negative electrode collector 3, the Coating II2 is coated on the other surface of negative electrode current collector 3, said coating I1 includes negative electrode active material I, conductive agent, thickener I, dispersant I and binder I, and said coating II2 includes Negative electrode active material II, conductive agent, thickener II, dispersant II and binder II, the viscosity of the thickener I is greater than that of the thickener II, the viscosity of the dispersant I is greater than that of the dispersant II, the The modulus of elasticity of binder I is greater than that of binder II.

[0027] Preferably, the thickener I and the thickener II are the same substance, the dispersant I and the dispersant II are the same substance...

specific Embodiment approach 2

[0037] The preparation method of lithium-ion battery negative electrode described in the specific embodiment one, comprises the following steps:

[0038] S1: Negative electrode active material I, conductive agent, thickener I, dispersant I and binder I are uniformly dispersed in a solvent to make negative electrode slurry A, and negative electrode slurry A is coated on one of the negative electrode current collectors 3 A coating I1 is formed on the surface;

[0039] S2: Negative electrode active material II, conductive agent, thickener II, dispersant II, and binder II are uniformly dispersed in a solvent to make negative electrode slurry B, and negative electrode slurry B is coated on the other side of the negative electrode current collector 3 A coating II2 is formed on one surface;

[0040] S3: The negative electrode current collector 3 coated with the negative electrode slurry A and the negative electrode slurry B is dried to remove the solvent, and the negative electrode ...

specific Embodiment approach 3

[0044] The method for preparing a negative electrode of a lithium-ion battery described in the specific embodiment 2, in step S1, the specific preparation method of the negative electrode slurry A is:

[0045] Step 1: 10% to 40% of the total mass of the thickener I and dispersant I and all the conductive agents are mixed and evenly dispersed in the solvent;

[0046] Step 2: Then add 20% to 30% of the total mass of the negative electrode active material I and 20% to 30% of the total mass of the thickener I and dispersant I, and disperse evenly;

[0047] Step 3: adding 20% to 30% of the total mass of the negative electrode active material I and 30% to 70% of the total mass of the thickener I and dispersant I, and disperse evenly;

[0048] Step 4: adding 20% to 30% of the total mass of the negative electrode active material I, and dispersing evenly;

[0049]Step 5: adding 10% to 40% of the total mass of the negative electrode active material I, and dispersing evenly;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com