Silicon carbon composite anode material of lithium-ion battery, method for preparing silicon carbon composite anode material, and lithium-ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as inability to effectively inhibit silicon volume expansion and poor cycle performance of negative electrode materials, and achieve improved electrochemical stability and improved Specific capacity and cycle performance, effect of improving volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

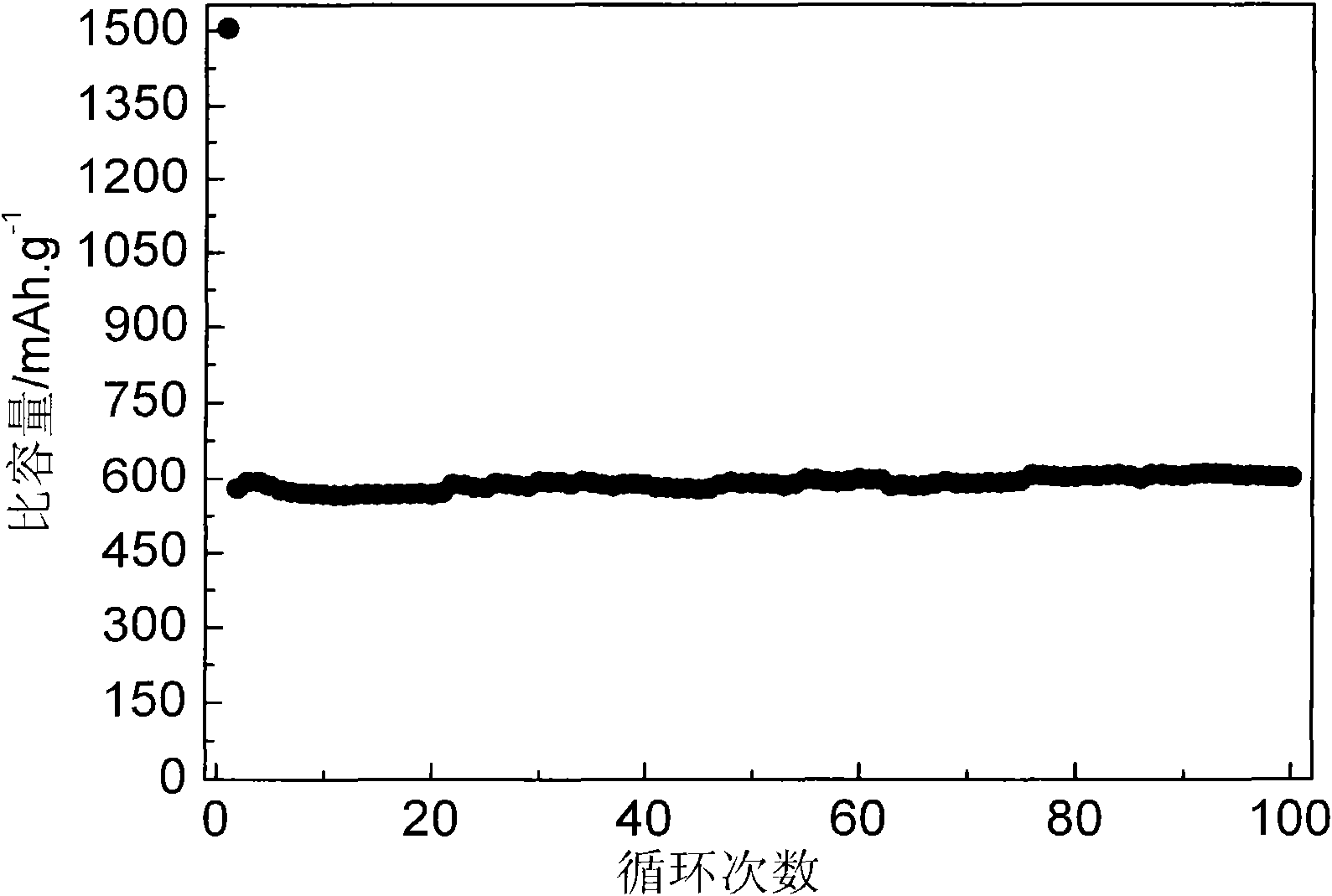

[0029] Weigh 1g of silicon powder, 1.2g of graphite and 0.8g of expanded graphite, mix them uniformly, put them into a ball mill, and ball mill for 12 hours at a speed of 400r / min to obtain the product silicon-carbon composite negative electrode material for lithium-ion batteries.

[0030] The obtained negative electrode material is mixed with conductive agent acetylene black and binder PVDF (polyvinylidene fluoride) according to the mass ratio of 80:10:10, and the mixture is prepared into slurry with NMP (1-methyl-2-pyrrolidone) , uniformly coated on the copper foil, and dried for 24 hours at 80°C under a vacuum of 0.02MP to obtain a pole piece for an experimental battery. With lithium sheet as the counter electrode, the electrolyte is 1mol / L LiPF 6 EC (ethyl carbonate) + DMC (dimethyl carbonate) (volume ratio 1:1) solution, the diaphragm is celgard2400 film, assembled into a CR2025 button cell in a glove box filled with an argon atmosphere.

[0031] After testing, the first...

Embodiment 2

[0033] Weigh 1g of SiO powder, 1.2g of graphite and 0.8g of expanded graphite, mix them evenly, put them into a ball mill, and ball mill for 8 hours at a speed of 500r / min to obtain the product silicon-carbon composite negative electrode material for lithium-ion batteries.

[0034] The lithium-ion battery was prepared by the method described in Example 1. After testing, the first discharge specific capacity reached 923mAh / g, and remained at 393mAh / g after 100 cycles.

Embodiment 3

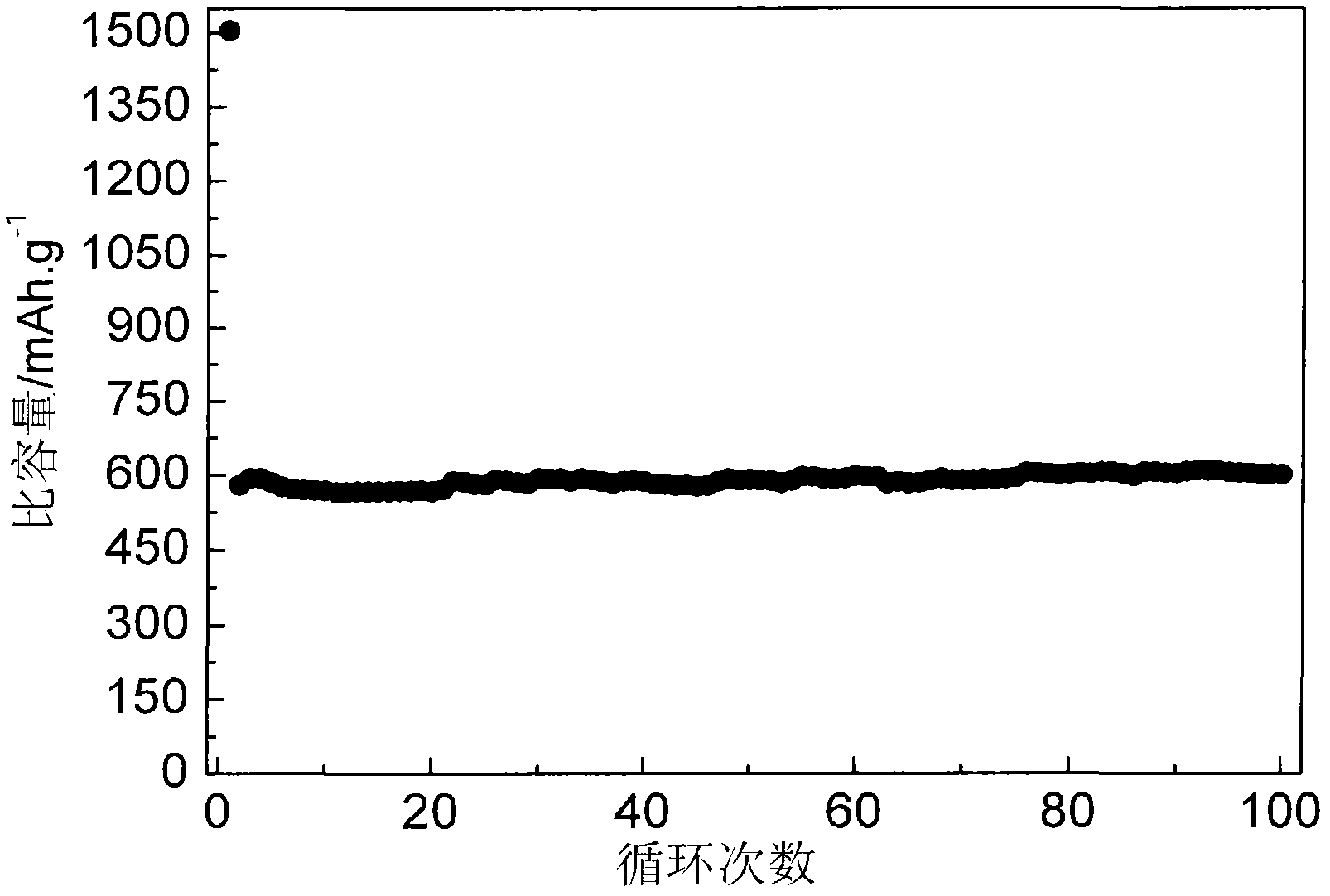

[0036]Weigh 0.5g of silicon powder, 0.5g of SiO powder, 1.2g of graphite and 0.8g of expanded graphite, mix them uniformly, put them into a ball mill, and ball mill at a speed of 300r / min for 20h to obtain the product silicon-carbon composite negative electrode material for a lithium-ion battery.

[0037] The lithium-ion battery was prepared by the method described in Example 1. After testing, the first discharge specific capacity reached 1123mAh / g, and remained at 550mAh / g after 100 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com