Graphite/silicon/graphene composite material and preparation method thereof

A silicon composite material and composite material technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of limited development and practical application, deterioration of cycle performance, etc., to improve the first efficiency and cycle performance, and improve the volume. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

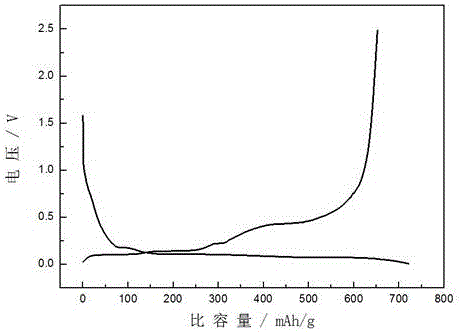

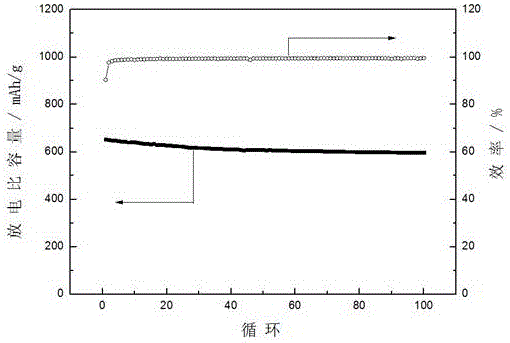

Examples

Embodiment 1

[0028] 1) Weigh 100g of NMP solution and put it into a 500ml beaker, add 5g of graphene powder and 2g of polyvinylpyrrolidone into the beaker, put the beaker into an ultrasonic cleaner and vibrate ultrasonically for 20min to obtain a graphene dispersion;

[0029] 2) Weigh 87g of natural graphite, 3g of low-temperature coal tar pitch and 5g of nano-silicon powder into the mixer, set the temperature of the mixer at 70°C, and stir at this temperature for 5 hours to obtain a silicon / graphite composite material;

[0030] 3) Continue to stir the graphene dispersion obtained in step 1) and the graphite / silicon composite material obtained in step 2) in a mixer for 1 hour, and the taken out materials are dried, calcined, pulverized, and classified to obtain graphite / silicon / graphene composites.

Embodiment 2

[0032] 1) Weigh 100g of NMP solution into a 500ml beaker, add 7g of graphene powder and 3g of polyvinylpyrrolidone into the beaker, put the beaker into an ultrasonic cleaner and oscillate ultrasonically for 20min to obtain a graphene dispersion;

[0033] 2) Weigh 85g of graphite, 3g of medium-temperature coal tar pitch and 5g of nano-silicon powder into the mixer, set the temperature of the mixer at 90°C, and stir at this temperature for 5 hours to obtain a silicon / graphite composite material;

[0034] 3) Continue to stir the graphene dispersion obtained in step 1) and the graphite / silicon composite material obtained in step 2) in a mixer for 1 hour, and the taken out materials are dried, calcined, pulverized, and classified to obtain graphite / silicon / graphene composites.

Embodiment 3

[0036] 1) Weigh 100g of NMP solution into a 500ml beaker, add 10g of graphene powder and 4g of polyvinylpyrrolidone into the beaker, put the beaker into an ultrasonic cleaner and oscillate ultrasonically for 20min to obtain a graphene dispersion;

[0037] 2) Weigh 82g of graphite, 3g of medium-temperature coal tar pitch and 5g of nano-silicon powder into the mixer, set the temperature of the mixer at 100°C, and stir at this temperature for 5 hours to obtain a silicon / graphite composite material;

[0038] 3) Continue to stir the graphene dispersion obtained in step 1) and the graphite / silicon composite material obtained in step 2) in a mixer for 1 hour, and the taken out material can be dried, calcined, pulverized, and classified to obtain graphite / silicon composite material. Silicon / graphene composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com