Method for preparing silicon composite cathode material of lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, which is applied in electrode manufacturing, battery electrodes, silicon, etc., can solve the problems of poor material cycle performance, difficult to guarantee reproducibility, complicated processing process, etc., and achieve good cycle stability, heavy duty, etc. Good reproducibility and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

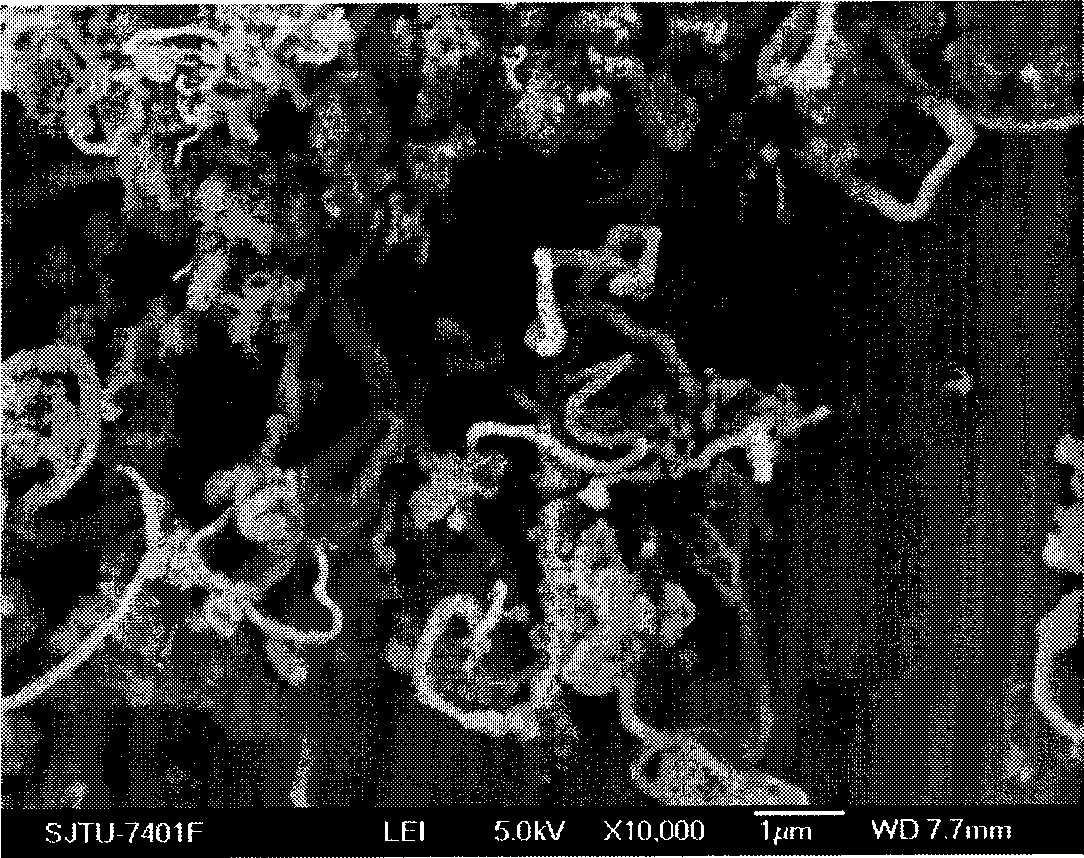

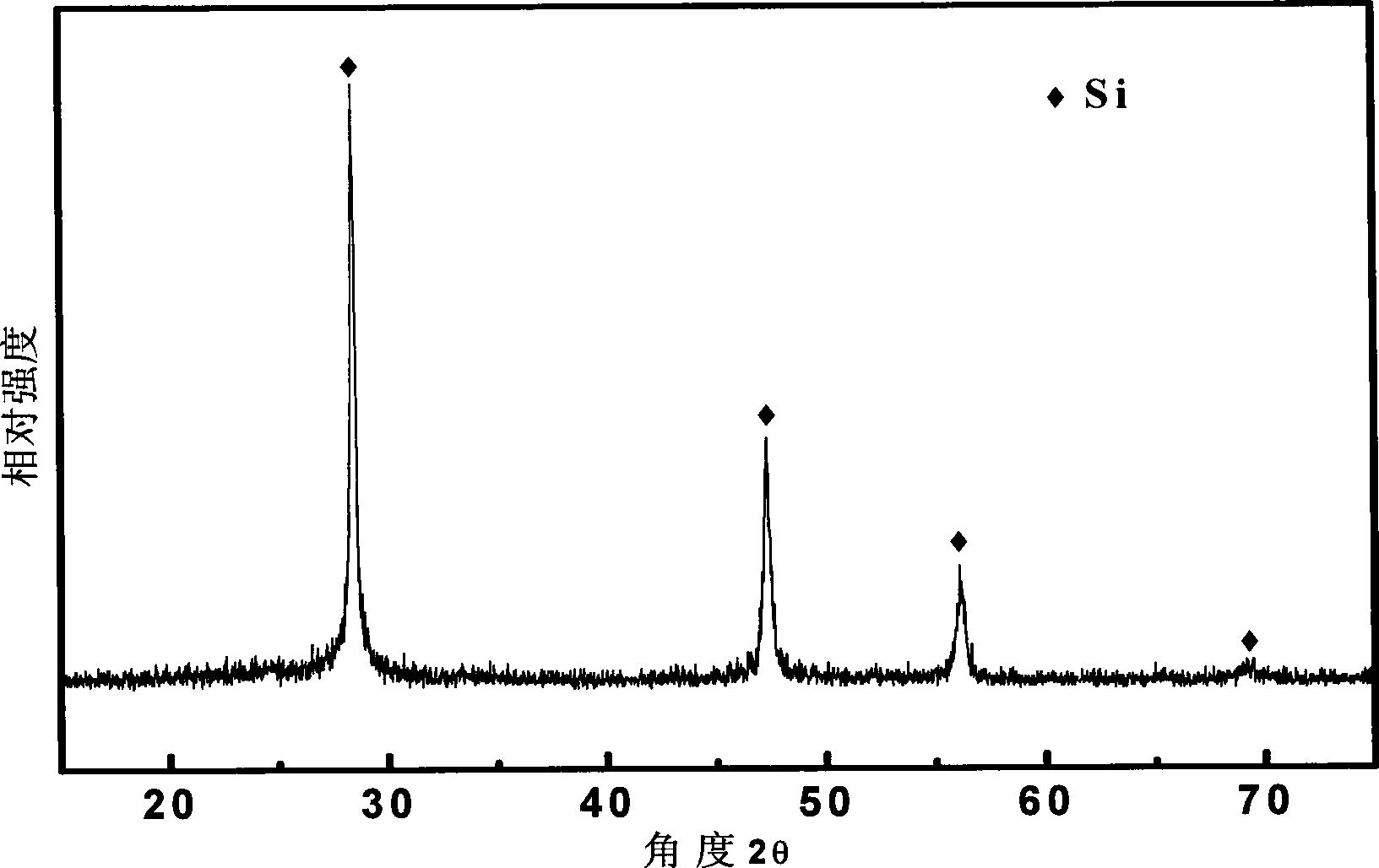

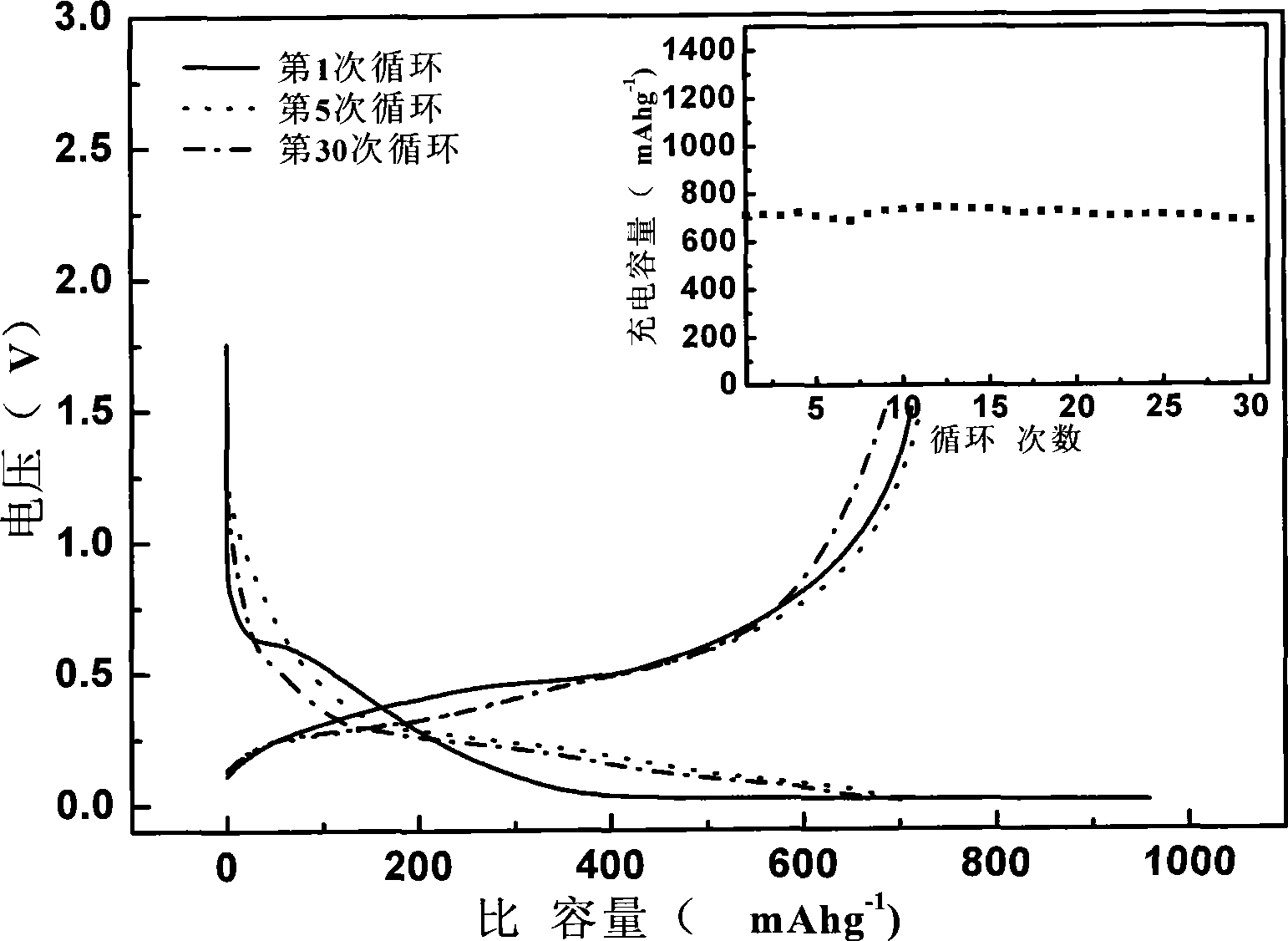

[0030] (1) Under the protection of argon at 20°C, 0.8394g of Li 2 Si powder and 0.4g of carbon black powder are mixed in 2.96g of silicon tetrachloride liquid, are placed in 80ml stainless steel ball mill tank, put into 15 stainless steel balls, keep argon gas in the stainless steel ball mill tank, carry out ball mill, high-energy ball mill The rotating speed is 450 rpm, and the ball milling time is 20 hours to obtain a nano-silicon / carbon black / lithium chloride complex;

[0031] (2) Open the stainless steel ball mill tank under the protection of argon and transfer the nano-silicon / carbon black / lithium chloride complex to the quartz boat, heat treatment at 700°C for 6 hours under the protection of argon, and naturally cool to 20°C; then Transfer to absolute ethanol and stir for 1 hour, and ultrasonic treatment for 10 minutes, centrifuged, and then vacuum-dried at 100 ° C for 4 hours to obtain a nano-silicon / carbon black composite;

[0032] (3) Disperse 0.2g of nano-silicon / ca...

Embodiment 2

[0039] (1) Under the protection of argon at 15°C, 0.8394g of Li 2 Si powder and 0.5g of graphite powder are added to 2g of silicon tetrabromide liquid and mixed, placed in an 80ml stainless steel ball mill tank, 15 stainless steel balls are put into the stainless steel ball mill tank to keep argon gas for ball milling, and the speed of the high energy ball mill is For 400 rev / min, the ball milling time is 10 hours to obtain nano-silicon / graphite / lithium bromide composite;

[0040] (2) Open the stainless steel ball mill tank under the protection of argon and transfer the nano-silicon / graphite / lithium bromide complex to a quartz boat, heat-treat at 200°C for 3 hours under the protection of argon, and cool naturally to 15°C; then transfer to water Stirring for 2 hours, ultrasonic treatment for 30 minutes, centrifugation, and then vacuum drying at 110°C for 10 hours to obtain a nano-silicon / graphite composite;

[0041] (3) Disperse 0.2g of nano-silicon / graphite composite and 0.5g...

Embodiment 3

[0043] (1) Under the protection of argon at 20°C, 0.6233g of Li 13 Si 4 Powder and 0.6g of carbon nanofiber powder are added to 3g of monochloroethylsilane liquid and mixed, placed in an 80ml stainless steel ball mill tank, put 15 stainless steel balls, and keep the stainless steel ball mill tank with argon gas for ball milling, high energy ball mill The rotating speed is 500 rpm, and the ball milling time is 20 hours to obtain nano-silicon / carbon nanofiber / ethyllithium-lithium chloride complex;

[0044] (2) Open the stainless steel ball mill tank under the protection of argon and transfer the nano-silicon / carbon nanofiber / ethyllithium-lithium chloride complex to a quartz boat, heat treat at 500°C for 5 hours under the protection of nitrogen, and cool naturally to 15 °C; then transferred to acetone and stirred for 1 hour, and ultrasonically treated for 20 minutes, centrifuged, and then vacuum-dried at 100°C for 6 hours to obtain a nano-silicon / carbon nanofiber composite;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore size distribution | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com