Metal oxide preparation method

An oxide and hydroxide technology, applied in the field of nanomaterials, can solve the problems of low product purity, environmental pollution, and complicated processes, and achieve the effects of high purity, simple raw material composition, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing metal oxides, comprising the steps of:

[0028] S01. Obtain an organic solvent dispersed with metals, the metals can react with water to form metal hydroxides;

[0029] S02, mixing the organic solvent in which the metal is dispersed with water and reacting to prepare a mixed solution containing metal hydroxide;

[0030] S03. Separating the mixed solution containing the metal hydroxide into solid and liquid, collecting the solid phase, and then calcining the solid phase to obtain the metal oxide, which has a micron or nanostructure.

[0031] The preparation method of the metal oxide provided by the embodiment of the present invention is to mix the organic solvent dispersed with the metal and water to prepare the metal hydroxide by reaction, and then perform solid-liquid separation of the mixed solution containing the metal hydroxide, and then perform calcination treatment, so that the metal hydroxide is dehydrated to form a metal oxide with a micr...

Embodiment 1

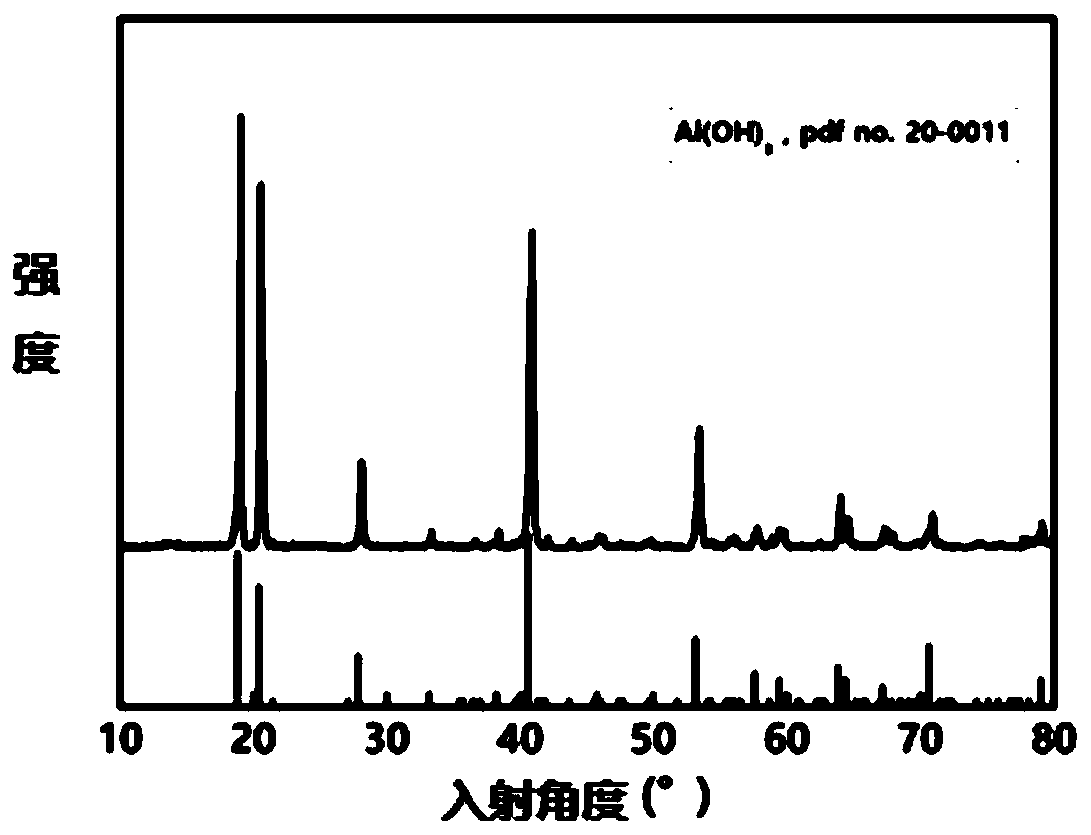

[0059] The present embodiment has prepared a kind of nano-alumina, specifically comprises the following steps:

[0060] 200 mg of Al nanosheets (prepared by the method disclosed in patent CN201811561463.X) were ultrasonically dispersed in 20 mL of acetone for 30 minutes to form a uniform suspension. Pour 40 mL of deionized water into the suspension with ultrasonic stirring, and continue vigorous ultrasonic stirring at 50°C for 1 hour. The original silver-gray suspension turned into a nearly colorless transparent aluminum hydroxide sol. The obtained aluminum hydroxide sol was subjected to suction filtration, and dried in an oven at 60° C. for 2 hours to obtain a white powder intermediate product.

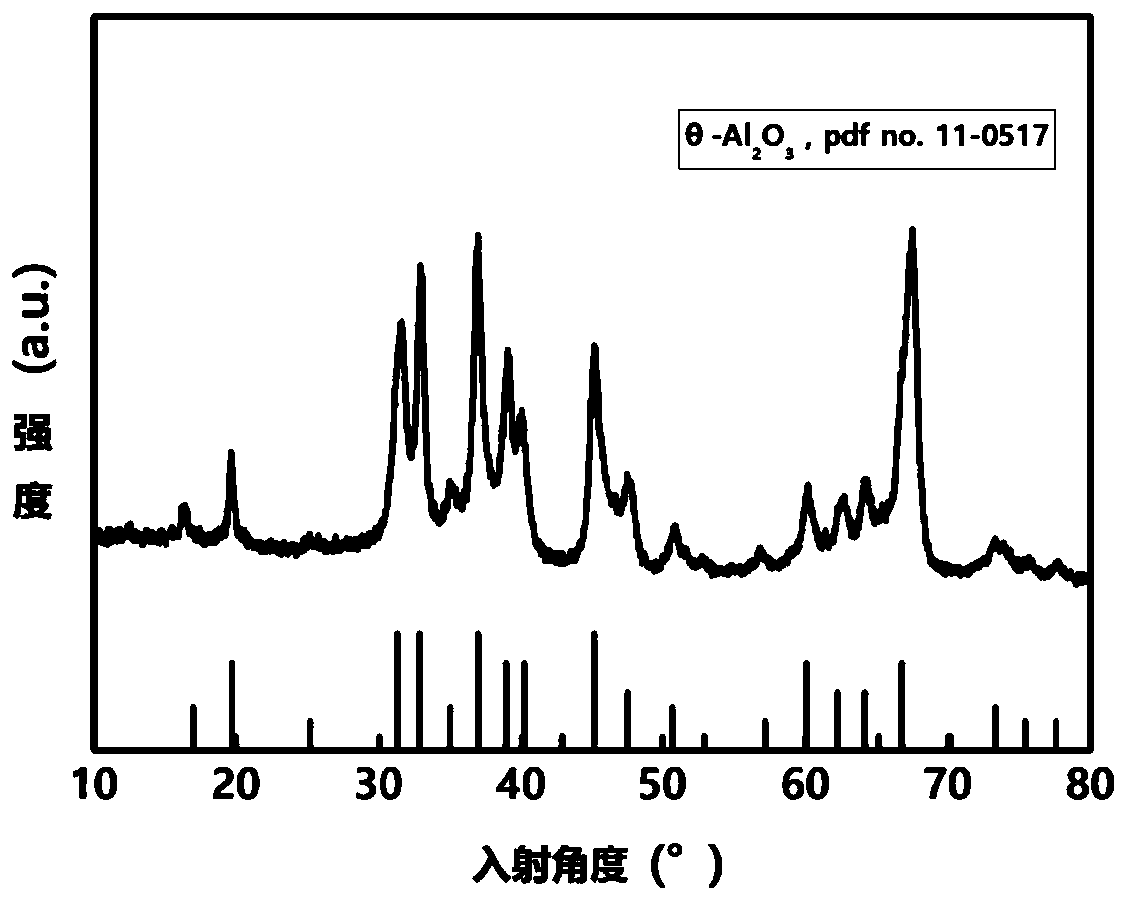

[0061] The obtained white powder intermediate product was calcined in a muffle furnace at 900°C for 2 hours to obtain θ-Al with a size of 10nm 2 o 3 nanoparticles.

[0062] Get the θ-Al that this embodiment makes 2 o 3 Nanoparticles were scanned by electron microscope, and the d...

Embodiment 2

[0065] The present embodiment has prepared a kind of nano-alumina, specifically comprises the following steps:

[0066] 200 mg of Al nanosheets were ultrasonically dispersed in 8 mL of acetone for 30 minutes to form a homogeneous suspension. Pour 40mL of deionized water into the suspension with ultrasonic stirring, and stir at 50°C for 2 hours without applying ultrasonic operation, the original silver-gray suspension becomes slightly white transparent aluminum hydroxide sol . The obtained sol was subjected to suction filtration, and dried in an oven at 80° C. for 1.5 hours to obtain a white powder. The resulting white powder was calcined in a muffle furnace at 1050°C for 1.5 hours to obtain θ-Al with a thickness of 10-50nm 2 o 3 Nanosheets.

[0067] Get the θ-Al that embodiment 2 makes 2 o 3 The nanosheets were scanned by electron microscope, and the detection results were as follows: Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com