Lyocell crimped fiber

A technology of crimping fibers and fibers, which is applied in the field of lyocell fibers, can solve problems such as non-excellence, and achieve the effect of improving expansion performance and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

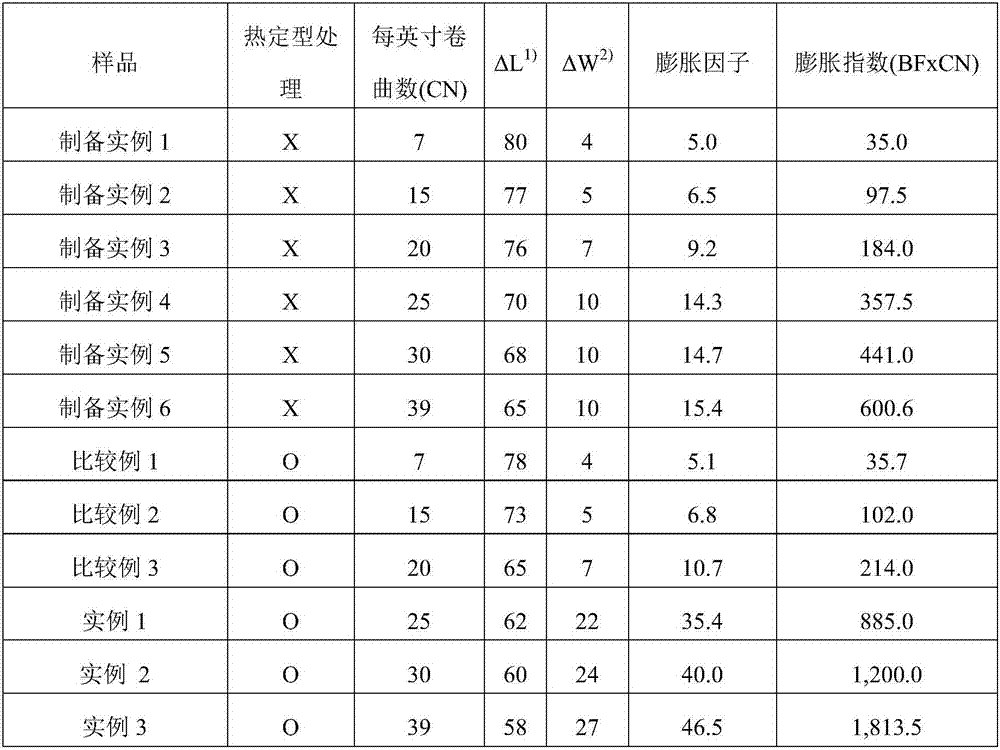

preparation example 1

[0062] A cellulose pulp with a degree of polymerization (DPw) of 820 and an α-cellulose content of 93.9% and NMMO / H with a propylate content of 0.01% by weight 2 O mixed solvents (90 / 10 by weight) were mixed to prepare a 12% by weight spinning dope for preparing lyocell fibers.

[0063] First, the spinning solution was kept at a spinning temperature of 110° C. in the spinning nozzle of the spinneret, and the single fineness of the filament was 3.37 denier while adjusting the discharge amount of the spinning solution and the spinning speed. The spinning solution is spun. The filamentous spinning solution discharged from the spinning nozzle is fed into the solidification solution of the solidification bath through the air gap part. The spinning dope was first solidified in the air gap portion using cooling air at a temperature of 8° C. and a wind speed of 10 m / s.

[0064] The curing solution contained 85% by weight water and 15% by weight NMMO at 25°C. The concentration of th...

preparation example 2 to 6

[0068] Using the same method as Preparation Example 1 to manufacture lyocell crimped fibers, the difference is to change the pressure of the press roller, thus obtaining the number of crimps as 15 (ea / inch), 20 (ea / inch), 25 (ea / inch) ), 30 (ea / inch) and 39 (ea / inch) of Preparative Example 2 to Preparative Example 6. However, even when the pressure of the press roll became 39 ea / inch or more, the number of crimps did not increase any more. Therefore, in the production example, the crimp number variation was as high as 39 ea / inch.

example 1 to example 3

[0070] Lyocell crimped fibers (Examples 1 to 3) with crimp numbers of 25 (ea / inch), 30 (ea / inch) and 39 (ea / inch) were prepared using the same method as Preparation Example 4 to Preparation Example 6, different The point is that by using a steam box at 1.0kgf / cm 2Steam (120° C.) was provided under pressure to heat set the lyocell fibers before they passed through the press rolls in the stuffing box.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| ductility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com