Three-dimensional composite metal lithium negative electrode, metal lithium battery and device

A three-dimensional composite and metal lithium technology, applied in the field of electrochemistry, can solve the problems of fast consumption of electrolyte, easy cracking, consumption of electrolyte, etc., to reduce the overpotential of lithium nucleation, reduce the overpotential of lithium deposition, and inhibit lithium dendrites The effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

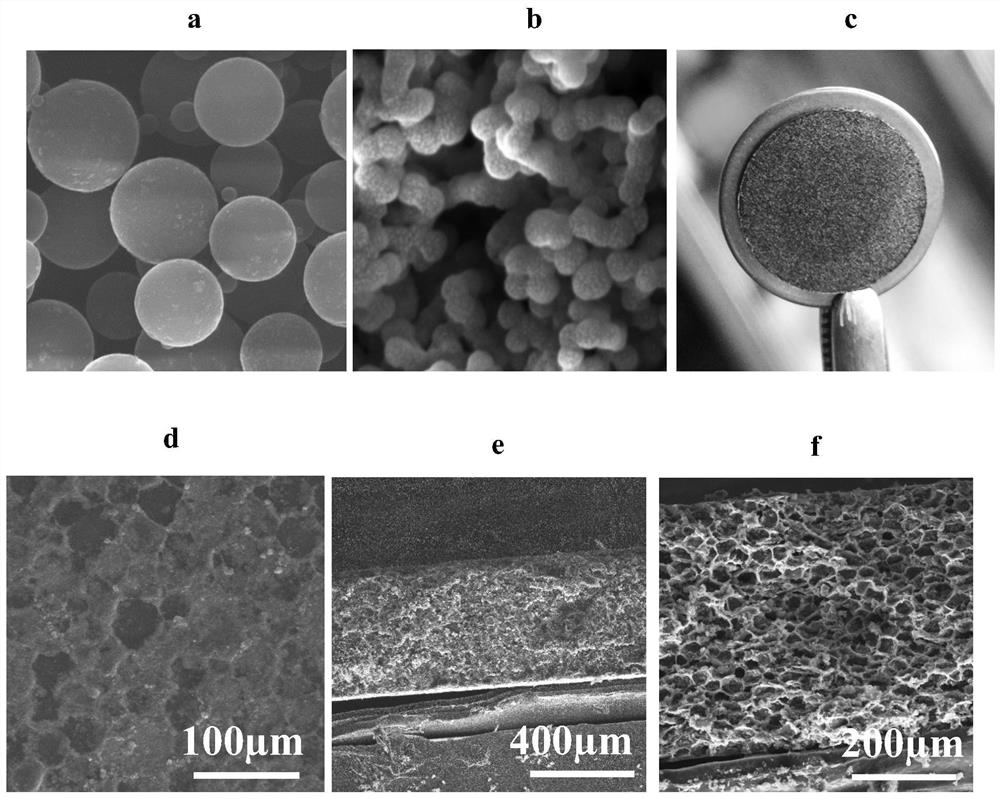

[0067] 1. Preparation of three-dimensional composite metal lithium anode:

[0068] Using magnesium oxide (MgO) nanoparticles, sulfur (S) powder, polyacrylonitrile (PAN) powder, metal lithium particles and carbon nanotubes as raw materials, the preparation is carried out according to the following steps:

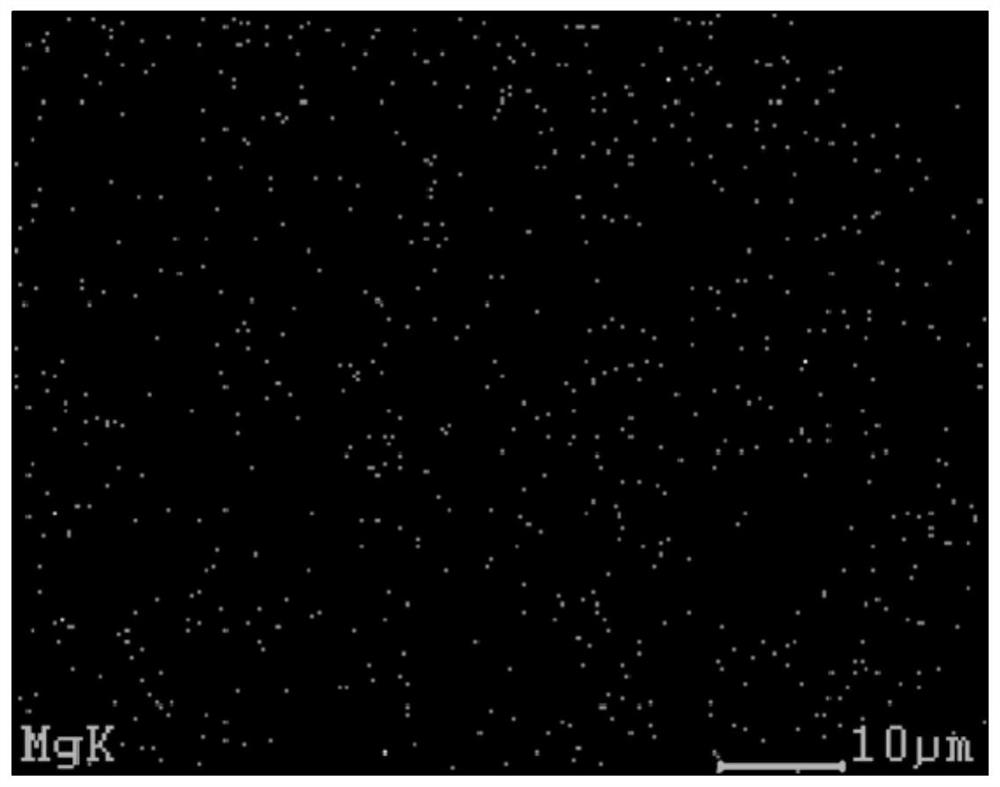

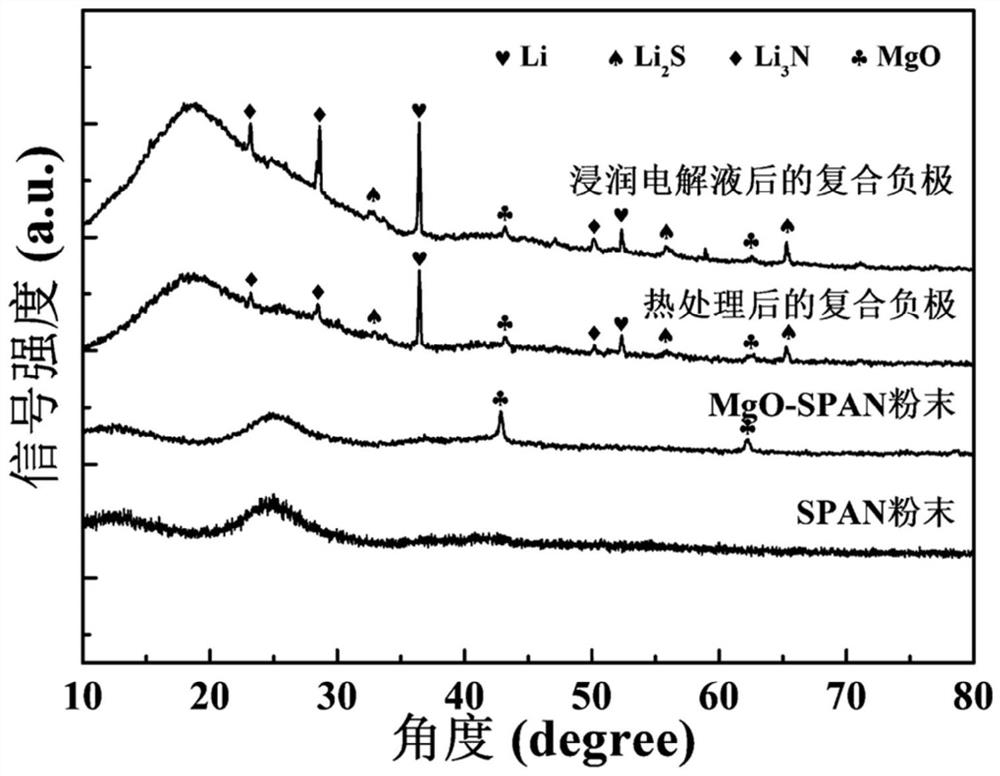

[0069] S1) Mix S, PAN, and MgO nanoparticles according to the mass ratio of 80g:10g:10g and ball mill for 6h, then calcinate at 300°C for 6h in an anhydrous and oxygen-free environment to obtain MgO-SPAN powder, which is crushed and sieved.

[0070] S2): In an anhydrous and oxygen-free environment, mix MgO-SPAN powder (particle size 100-200nm) and metal lithium particles (particle size 10-50μm) according to the mass ratio of 1:3 and grind them evenly.

[0071] S3): In an anhydrous and oxygen-free environment, after adding 10 wt% (based on the weight of all raw materials added) carbon nanotubes with a length of 15 μm and an inner diameter of 1-10 nm to the mixture obtained in ...

Embodiment 2

[0082] The preparation process of the three-dimensional composite lithium metal negative electrode, the lithium-containing negative electrode / lithium-containing negative electrode symmetrical battery, and the lithium battery in this example is the same as that in Example 1, except that the heat treatment temperature of the three-dimensional composite lithium metal negative electrode is 100°C.

Embodiment 3

[0084] The preparation process of the three-dimensional composite metal lithium negative electrode, the lithium-containing negative electrode / lithium-containing negative electrode symmetric battery, and the lithium battery in this example is the same as that in Example 1, except that the heat treatment temperature of the three-dimensional composite metal lithium negative electrode is 200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com