Preparation method of silicon carbon negative electrode material, silicon carbon negative electrode material and lithium ion battery

A negative electrode material, silicon carbon technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of insignificant improvement in cycle performance, unfavorable industrial development and application, and poor results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] In the first aspect, this embodiment provides a method for preparing a silicon-carbon negative electrode material, comprising the following steps:

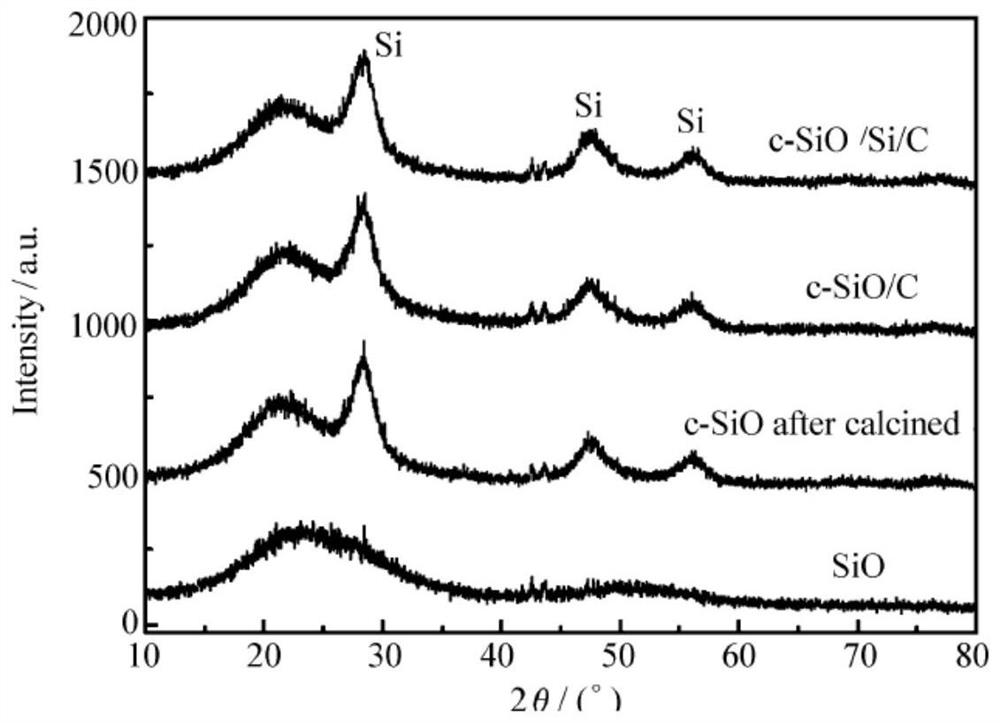

[0054] (a) using silicon monoxide as the base material, heat-treating silicon monoxide to cause disproportionation reaction of silicon monoxide to generate c-SiO;

[0055] (b) Place the c-SiO in a chemical vapor deposition furnace, raise the temperature under a protective atmosphere, and feed a carbon source after heating up to the reaction temperature, and conduct a vapor deposition reaction to obtain c-SiO / C; wherein the carbon The source is a solid or liquid compound;

[0056] (c) Etching the c-SiO / C with an etching solution to obtain the silicon-carbon negative electrode material c-SiO / Si / C.

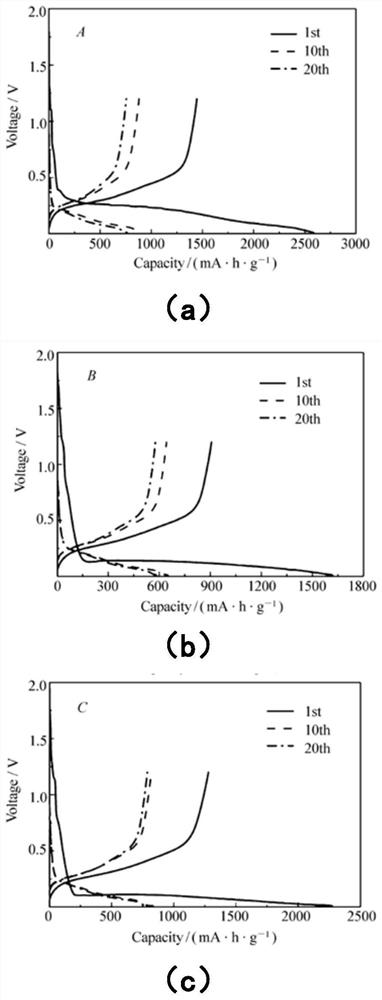

[0057] The silicon-carbon negative electrode material prepared by the preparation method of the silicon-carbon negative electrode material provided by the present invention can overcome the defect that the single use of silicon m...

Embodiment 1

[0120] A method for preparing a silicon-carbon negative electrode material, comprising the steps of:

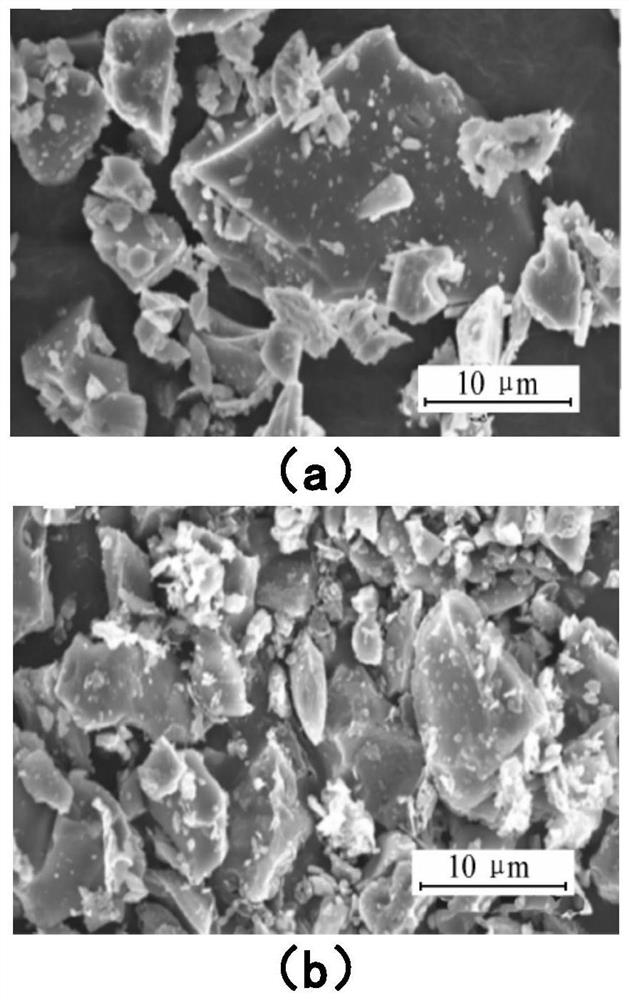

[0121] (a) disproportionation reaction: silicon monoxide is used as the base material, and the particle size of the silicon monoxide base material is 450 mesh, and the silicon monoxide is heated to cause disproportionation reaction of silicon monoxide to generate c-SiO;

[0122] (b) Vapor phase deposition reaction: place c-SiO in a chemical vapor deposition furnace, first purify it under the protection of argon for 0.5h, then raise the temperature to 1000°C at a heating rate of 5°C / min, and pass through the ferrocene ethanol solution , performing vapor deposition reaction for 3 hours to obtain c-SiO / C, wherein the content of C in c-SiO / C is 5wt%;

[0123] (c) Corrosion: put c-SiO / C in 5wt% hydrofluoric acid aqueous solution, stir and soak for 10 minutes, wash with deionized water, and dry at 100°C to obtain the silicon carbon negative electrode material c-SiO / Si / c.

Embodiment 2

[0125] A method for preparing a silicon-carbon negative electrode material, comprising the steps of:

[0126](a) disproportionation reaction: silicon monoxide is used as the base material, and the particle size of the silicon monoxide base material is 500 mesh, and the silicon monoxide is heated to cause disproportionation reaction of silicon monoxide to generate c-SiO;

[0127] (b) Vapor phase deposition reaction: place c-SiO in a chemical vapor deposition furnace, first purify it under the protection of argon for 0.5 h, then raise the temperature to 800 °C at a heating rate of 5 °C / min, and pass toluene for vapor phase deposition React for 2 hours to obtain c-SiO / C, wherein the content of C in c-SiO / C is 6wt%;

[0128] (c) Corrosion: put c-SiO / C in 5wt% hydrofluoric acid aqueous solution, stir and soak for 15 minutes, wash with deionized water, and dry at 100°C to obtain the silicon carbon negative electrode material c-SiO / Si / c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com