Preparation method of silicon carbon negative pole composite material

A composite material and negative electrode technology, which is applied in the field of preparation of silicon-carbon negative electrode composite materials, can solve the problems of rapid capacity decay, low theoretical capacity market demand, poor conductivity, etc., to improve electrochemical stability, improve silicon volume effect, increase The effect of embedding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing a silicon-carbon negative electrode composite material, comprising the following steps:

[0023] (1) Disperse a certain proportion of silicon powder and carbon source in deionized water, stir for a period of time, transfer to a polytetrafluoroethylene reactor, coat the carbon precursor on the surface of silicon powder by hydrothermal method, and then calcinate in an inert atmosphere Silicon powder is one of monocrystalline silicon and polycrystalline silicon, and the carbon source is one or more mixtures of sucrose, lactose, glucose, starch, cellulose, polyvinyl alcohol, citric acid, and the water The treatment temperature of the thermal method is 140-220° C., and the treatment time of the hydrothermal method is 4-12 hours.

[0024] (2) Disperse the calcined material in step (1) in the mixed solution a, disperse at a high speed and then perform drying treatment. The mixing mass ratio of the calcined material to the mixed solution a is 1:2-15, pref...

Embodiment 1

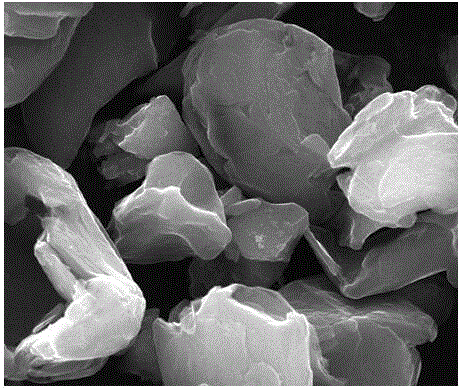

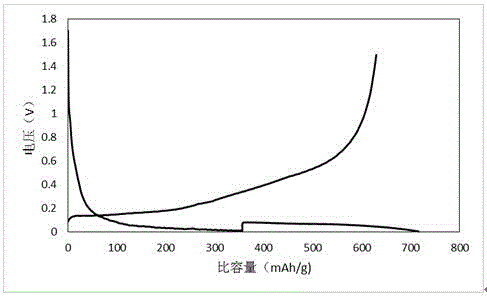

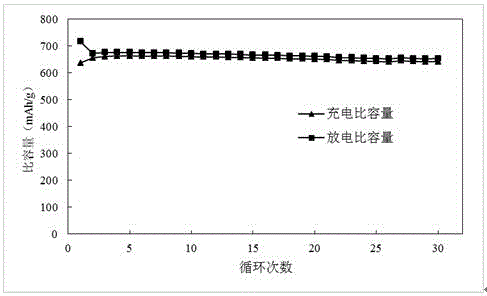

[0034] Dissolve monocrystalline silicon powder with an average particle size of 1 micron and sucrose in deionized water at a mass ratio of 1:3, and control the solid content to 25%. The resulting solution is stirred at a speed of 600 rpm for 1 hour, and the stirred solution is transferred to Put it in a polytetrafluoroethylene reaction kettle, keep it warm at 180°C for 10h, centrifuge the heat-treated product, dry the centrifuged sample, and put it under N 2 Calcination treatment was carried out at 500°C under protection, the heating rate was 10°C / min, and the holding time was 4h. The calcined sample and graphene were dissolved in ethanol solution at a mass ratio of 1:5, and the solid content was controlled at 15%. The obtained solution was stirred at a high speed of 2000rpm for 1h, followed by suction filtration, and then dried. The dried sample was corroded with a 5% HF solution. The mass ratio of the sample to the corrosion solution was 1:50, and the corrosion time was 2h. ...

Embodiment 2

[0039] Dissolve monocrystalline silicon powder with an average particle size of 5 microns and citric acid in deionized water at a mass ratio of 1:5, and control the solid content to 20%. The resulting solution is stirred at a speed of 600 rpm for 1 hour, and the stirred solution is Transfer to a polytetrafluoroethylene reactor, keep it warm at 200°C for 8 hours, centrifuge the heat-treated product, dry the centrifuged sample, and store it in N 2 Calcination treatment was carried out at 600°C under protection, the heating rate was 10°C / min, and the holding time was 4h. The calcined sample and graphene were dissolved in acetone solution at a mass ratio of 1:10, and the solid content was controlled at 15%. The obtained solution was stirred at a high speed of 1500rpm for 2 hours, followed by suction filtration, and then dried. The dried sample was corroded with 10% HF solution. The mass ratio of the sample to the corrosion solution was 1:30, and the corrosion time was 2 hours. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com