Preparation method for silicon-carbon composite material, prepared silicon-carbon composite material, lithium ion battery anode containing silicon-carbon composite material and battery

A silicon-carbon composite material, porous carbon technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of structural damage, unfavorable volume expansion, high price of nano-silicon powder, etc., and achieve improved specific capacity. and cycle performance, improve electrochemical stability, and improve the effect of silicon volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Now, the present invention will be further described in detail by taking the preparation method of a specific silicon-carbon composite material as an example.

[0031] The ultrasonic frequency used in the present invention is 40,000 Hz.

Embodiment 1

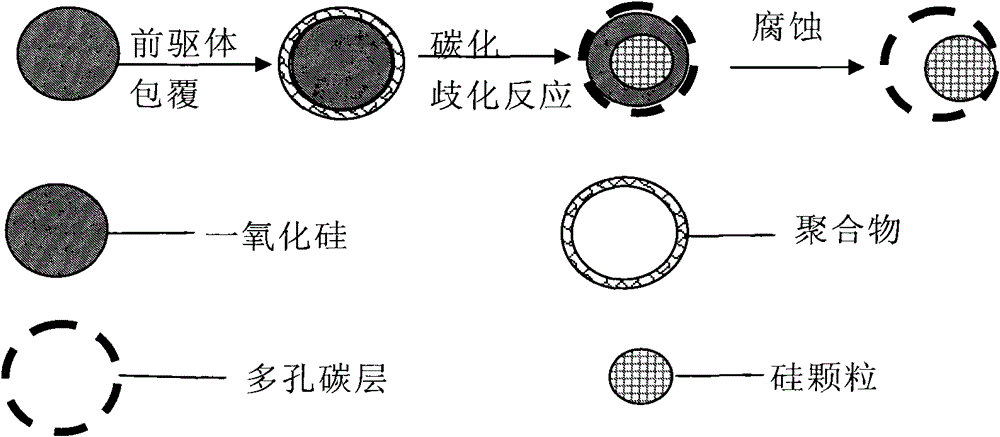

[0033] The preparation process of silicon-carbon composite materials with porous carbon spheres coated nano-silicon structure is as follows: figure 1 As shown, the specific steps are as follows:

[0034](1) Synthesis of polymer-coated SiO precursor: 2.20g catechol, 2ml formaldehyde (the molar ratio of phenolic monomer and aldehyde monomer is about 1:1) and 5ml concentrated hydrochloric acid (catalyst in the reactant solution 3.9mol / L) into 10ml of ethanol, stir to dissolve it completely, put it into the reactor, and add 0.9g of SiO powder into the reactor (the molar ratio of SiO powder to phenol monomer is about 1:1 ), after ultrasonic dispersion for 30 minutes, the resulting mixture was stirred and reacted at 85° C. for 1.5 h. After the above mixture reacted to form a gel, the reaction vessel was sealed and placed in an oven, and the reaction was continued at 120° C. for 8 h. Pound and grind the loose and porous brown substance obtained from the above reaction, put it in an...

Embodiment 2

[0041] (1) Synthesis of polymer-coated SiO precursor: 0.94g phenol, 1.1g hydroquinone, 4ml formaldehyde (phenol-formaldehyde molar ratio 1:2) and 0.5ml concentrated hydrochloric acid (the concentration of the catalyst in the reactant solution is 0.1mol / L) into 55ml of ethanol, stirred to dissolve completely, then put into the reactor, and added 1.8g of SiO powder (SiO powder to phenol monomer molar ratio 2:1) into the reactor, ultrasonically dispersed for 5 minutes The resulting mixture was then magnetically stirred at 60°C for 3 hours. After the above mixture reacted to form a gel, the reaction vessel was sealed and placed in an oven, and the reaction was continued at 60° C. for 24 h. The loose and porous brown substance obtained from the above reaction was crushed and ground, and dried in an oven at 90°C for 18 hours to obtain a phenolic resin polymer-coated SiO precursor;

[0042] (2) Heat treatment: heat the material obtained in step (1) under the protection of 95% argon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com