A kind of porous graphite and porous silicon composite negative electrode material and its preparation method and application

A technology of porous graphite and negative electrode materials, applied in graphite, battery electrodes, structural parts, etc., can solve the problems of low specific surface area and silicon element content, low theoretical specific capacity, and safety of composite negative electrode materials, so as to improve the electrochemical reaction Effects of rate, high theoretical specific capacity, and increased embedding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

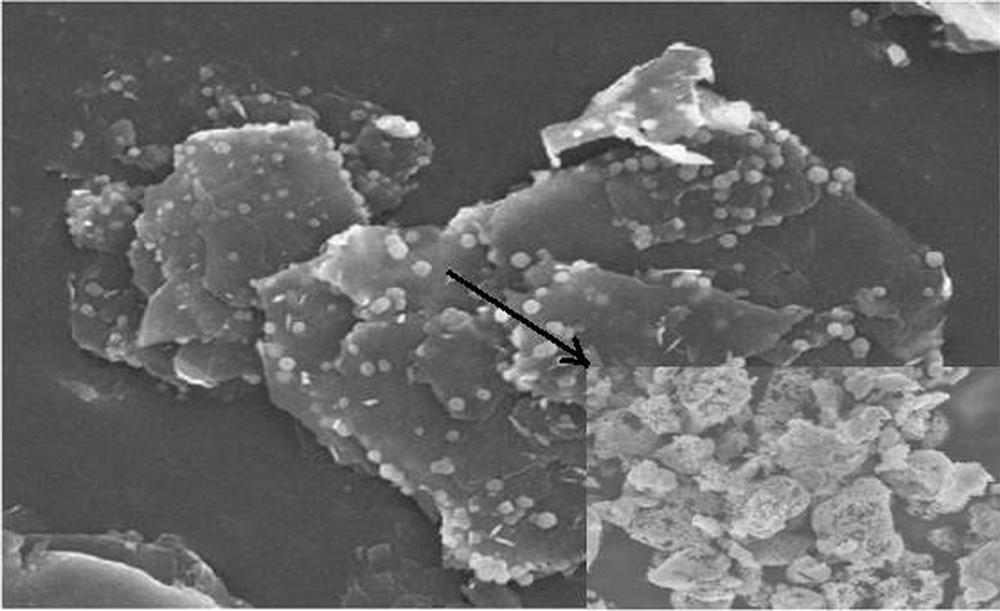

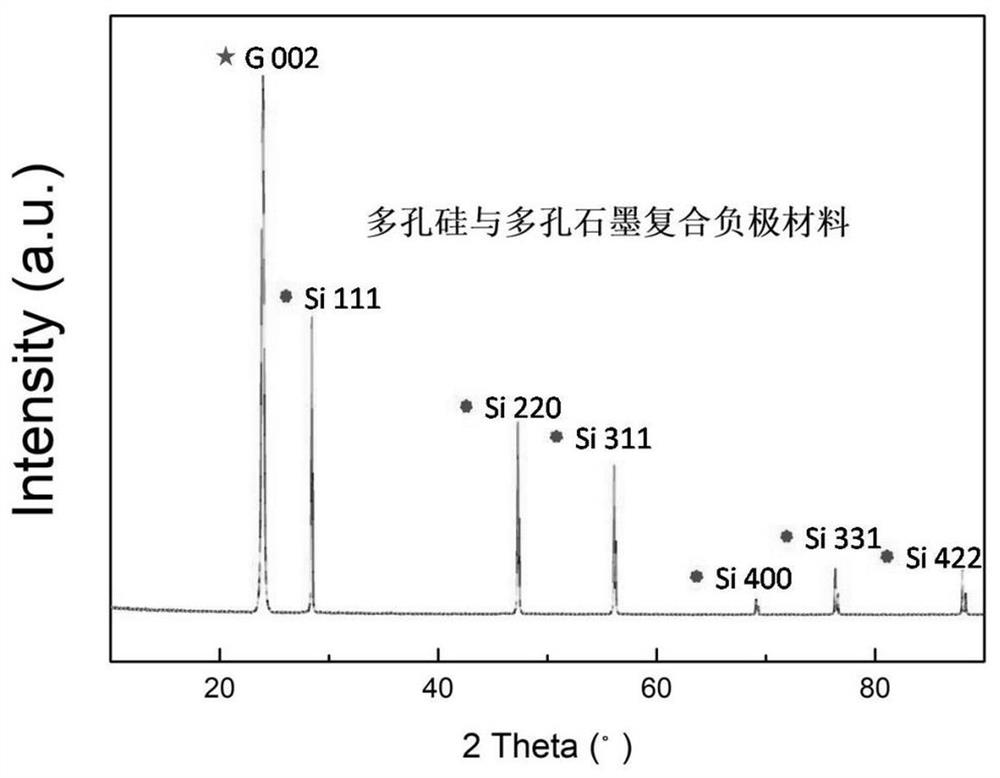

[0036] This embodiment 1 provides a method for preparing a porous graphite and porous silicon composite negative electrode material, which specifically includes the following steps:

[0037] (1) Wash the rice husk with deionized water and soak it in 2mol / L NaOH for 8h;

[0038] (2) Suction filter the biomass, wash it with deionized water, and dry it in a blast drying oven at a temperature of 105° C. for 4 hours to obtain dried biomass material, pulverize the biomass material in a micro-nano pulverizer, and pass 100-mesh sieve to obtain micron-sized biomass materials;

[0039](3) Place the micron-sized biomass material in a graphitization furnace under the protection of argon for stepwise heating. There are four stages in total. In the first stage, the heating rate is 5°C / min, and the temperature is raised to 500°C for the biomass material. The silicon compound is decomposed into silicon dioxide and pre-carbonized, and kept at a constant temperature for 4 hours; in the second ...

Embodiment 2

[0043] This embodiment 2 provides a method for preparing a porous graphite and porous silicon composite negative electrode material, which specifically includes the following steps:

[0044] (1) Wash the rice husk with deionized water and soak it in 2mol / L NaOH for 8h;

[0045] (2) Suction filter the biomass, wash it with deionized water, and dry it in a blast drying oven at a temperature of 105° C. for 4 hours to obtain dried biomass material, pulverize the biomass material in a micro-nano pulverizer, and pass 100-mesh sieve to obtain micron-sized biomass materials;

[0046] (3) Place the micron-sized biomass material in a graphitization furnace under the protection of argon for stepwise temperature rise. There are four stages in total. In the first stage, the temperature is raised to 400°C at a heating rate of 5°C / min. The silicon compound is decomposed into silicon dioxide and pre-carbonized, and kept at a constant temperature for 4 hours; in the second stage, the heating ...

Embodiment 3

[0050] This embodiment 3 provides a method for preparing a porous graphite and porous silicon composite negative electrode material, which specifically includes the following steps:

[0051] (1) Wash the rice husk with deionized water and soak it in 1mol / L KOH for 8h;

[0052] (2) Suction filter the biomass, wash it with deionized water, and dry it in a blast drying oven at a temperature of 110° C. for 2 hours to obtain dried biomass material, pulverize the biomass material in a micro-nano pulverizer, and pass 100-mesh sieve to obtain micron-sized biomass materials;

[0053] (3) Place the micron-sized biomass material in a graphitization furnace under the protection of argon for stepwise temperature rise. There are four stages in total. In the first stage, the temperature is raised to 450°C at a heating rate of 5°C / min. The silicon compound is decomposed into silicon dioxide and pre-carbonized, and kept at a constant temperature for 4 hours; in the second stage, the heating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com