A preparation method and product based on conductive carbon airgel composite nano-silicon negative electrode material

A negative electrode material, carbon aerogel technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of consumption capacity, direct contact, unfavorable composite silicon and carbon aerogel, etc., to alleviate volume expansion and contraction, The effect of increasing the embedding position and improving the excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

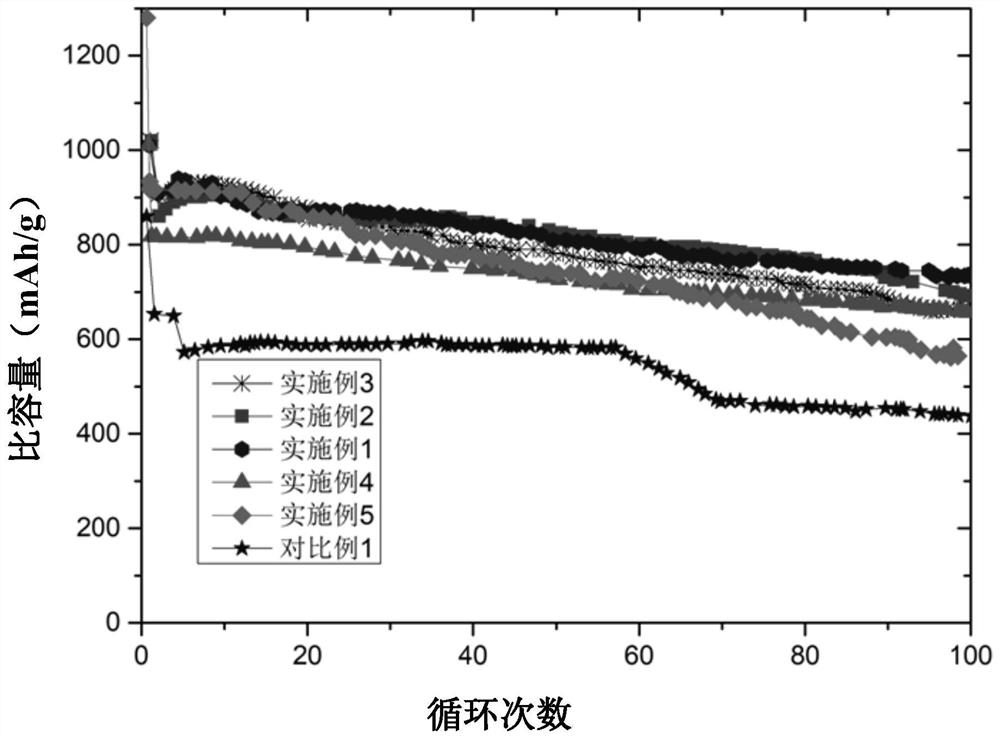

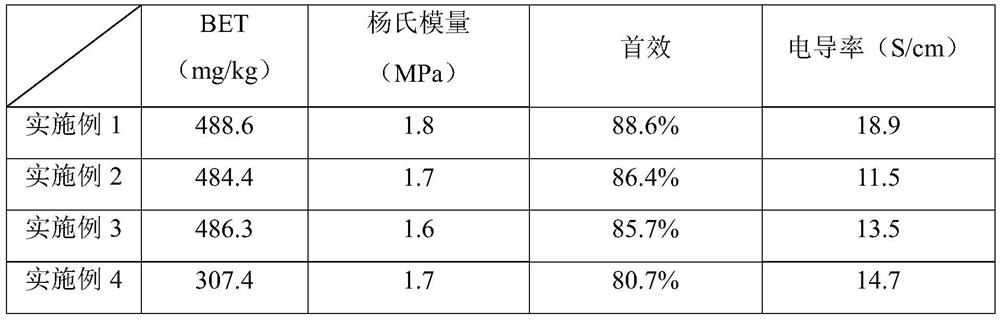

Embodiment 1

[0056] (1) Wash the discarded crab shells with deionized water, soak them in 2mol / L NaOH for 2 hours, remove the surface wax and pesticide residues, rinse them with deionized water, dry them and grind them roughly, then use 1mol / L hydrochloric acid solution for 30 minutes, and stirred at 100r / min to remove the calcium components in the crab shell, then washed with deionized water until neutral, dried, and selected crab shell powder with a D50 of 13-15 μm as the next step raw materials;

[0057] (2) Dissolve the pretreated crab shell powder in the NaOH aqueous solution of 4mol / L, and drop into 1wt% carbon nanotube fibers (the quality of the waste biomass after pretreatment is 100%, the same below), Stir until a reticular solid gel is obtained;

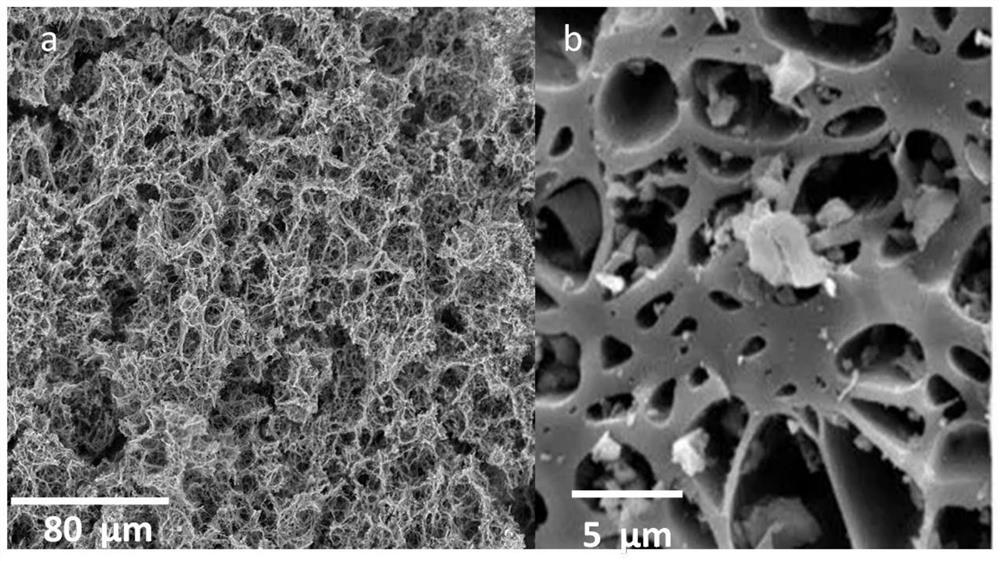

[0058] (3) Carry out freeze-drying treatment to the reticular solid gel, the temperature of the cold trap is -60 ℃, carry out sieving after drying, select the product of D50=8~9 μ m as carbon airgel precursor;

[0059] (4) Put the ca...

Embodiment 2

[0062] The preparation process is the same as that of Example 1, except that the carbon nanotube fibers added in step (2) are replaced with ceramic fibers.

Embodiment 3

[0064] The preparation process is the same as that of Example 1, except that the carbon nanotube fibers added in step (2) are replaced by glass fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com