Binder for lithium ion battery silicon-based negative electrode, negative electrode and preparation method thereof

A technology for lithium-ion batteries and silicon-based negative electrodes, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as damaged electrode structures, poor cycle performance, and loss of electrical contact, and achieves simple processes, improved Coulombic efficiency, and the first time The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

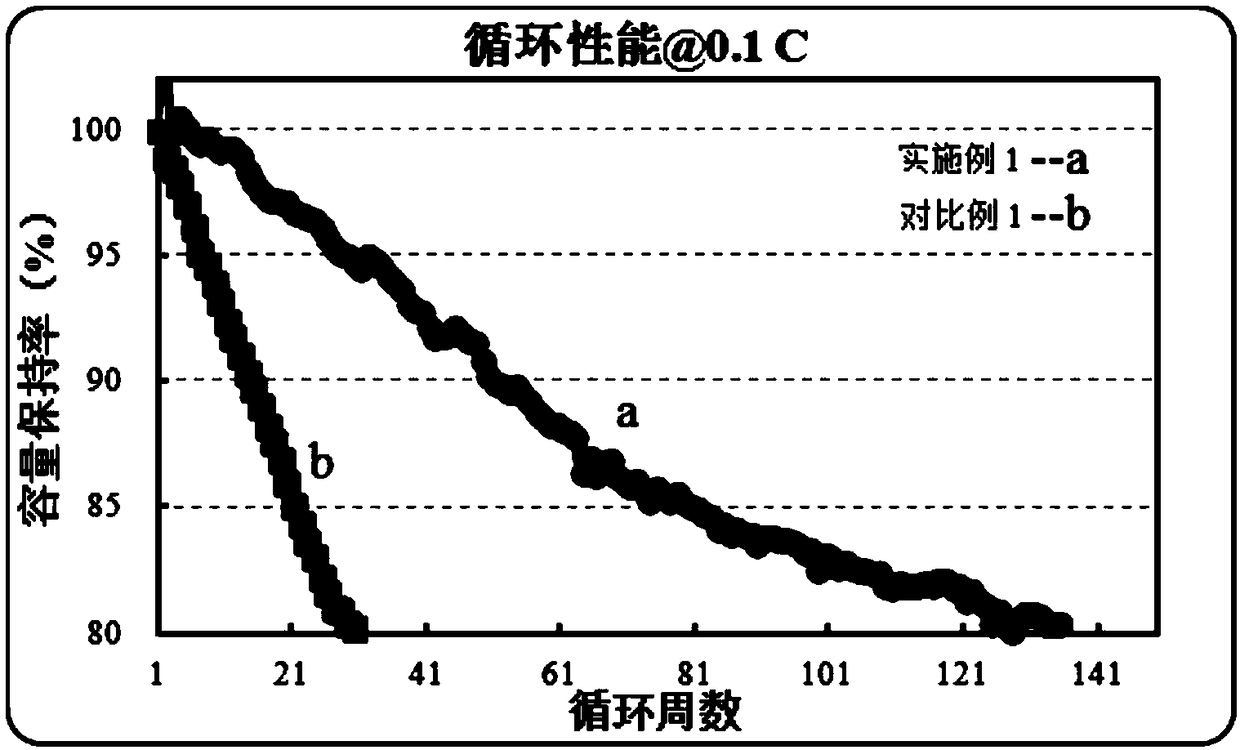

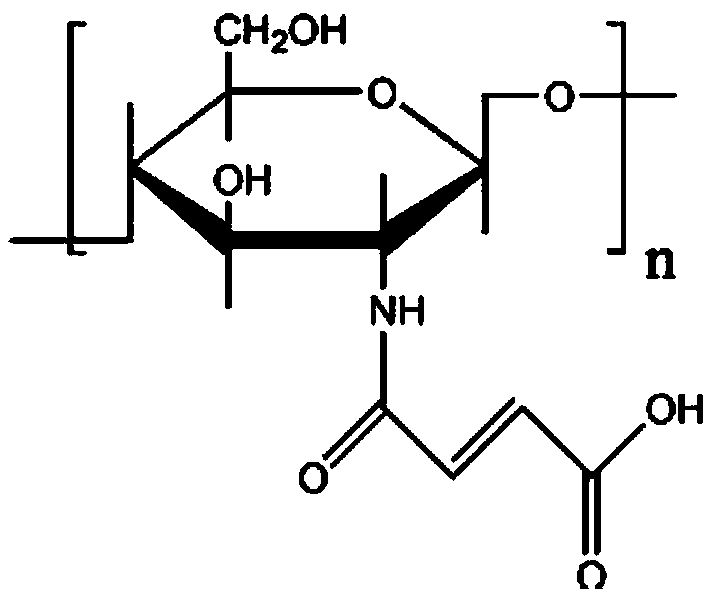

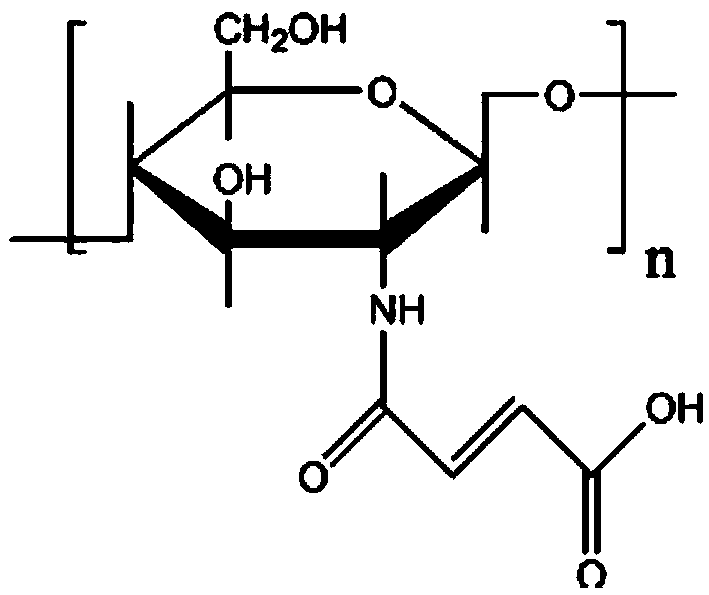

[0028] A kind of binding agent for silicon-based negative electrode of lithium ion battery that the present invention proposes is the maleic anhydride acylated chitosan m-CS that chitosan is carried out acylation modification by maleic anhydride, and its chemical formula is:

[0029]

[0030] The specific preparation is as follows: Weigh a certain amount of maleic anhydride and dissolve it in DMF to obtain a 5g / mL dispersion, then add CS, the mass ratio of chitosan to maleic anhydride is 1:3, N 2 After the temperature was raised to 120°C under the atmosphere, the reaction was continued for 3 hours, and finally the reaction solution was poured into ice water for precipitation, washed with ether three times and then dried to obtain the binder m-CS for silicon-based negative electrodes of lithium-ion batteries.

[0031] The present invention also proposes a lithium-ion battery silicon-based negative electrode containing the above-mentioned binder, which is prepared as follows: ...

Embodiment 2

[0033] A kind of binding agent for silicon-based negative electrode of lithium ion battery that the present invention proposes is the maleic anhydride acylated chitosan m-CS that chitosan is carried out acylation modification by maleic anhydride, and its chemical formula is:

[0034]

[0035] The specific preparation is as follows: Weigh a certain amount of maleic anhydride and dissolve it in DMF to obtain a 10g / mL dispersion, then add CS, the mass ratio of chitosan to maleic anhydride is 1:1, N 2 After the temperature was raised to 150°C under the atmosphere, the reaction was continued for 5 hours, and finally the reaction solution was poured into ice water for precipitation, washed with ether three times and then dried to obtain the binder m-CS for silicon-based negative electrodes of lithium-ion batteries.

[0036] The present invention also proposes a lithium-ion battery silicon-based negative electrode containing the above-mentioned binder, which is prepared as follows:...

Embodiment 3

[0038] A kind of binding agent for silicon-based negative electrode of lithium ion battery that the present invention proposes is the maleic anhydride acylated chitosan m-CS that chitosan is carried out acylation modification by maleic anhydride, and its chemical formula is:

[0039]

[0040] The specific preparation is as follows: weigh a certain amount of maleic anhydride and dissolve it in DMF to obtain a dispersion of 8 g / mL, then add CS, the mass ratio of chitosan to maleic anhydride is 1:2, N 2 After the temperature was raised to 140°C under the atmosphere, the reaction was continued for 4 hours, and finally the reaction solution was poured into ice water for precipitation, washed with ether three times and then dried to obtain the binder m-CS for silicon-based negative electrodes of lithium-ion batteries.

[0041] The present invention also proposes a lithium-ion battery silicon-based negative electrode containing the above-mentioned binder, which is prepared as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com