Graphene-silicon composite lithium ion battery negative electrode and preparation method thereof

A lithium-ion battery and graphene technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unfavorable industrialization development, high equipment requirements, poor cycle performance, etc., and achieve high specific capacity and high Coulombic efficiency , the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

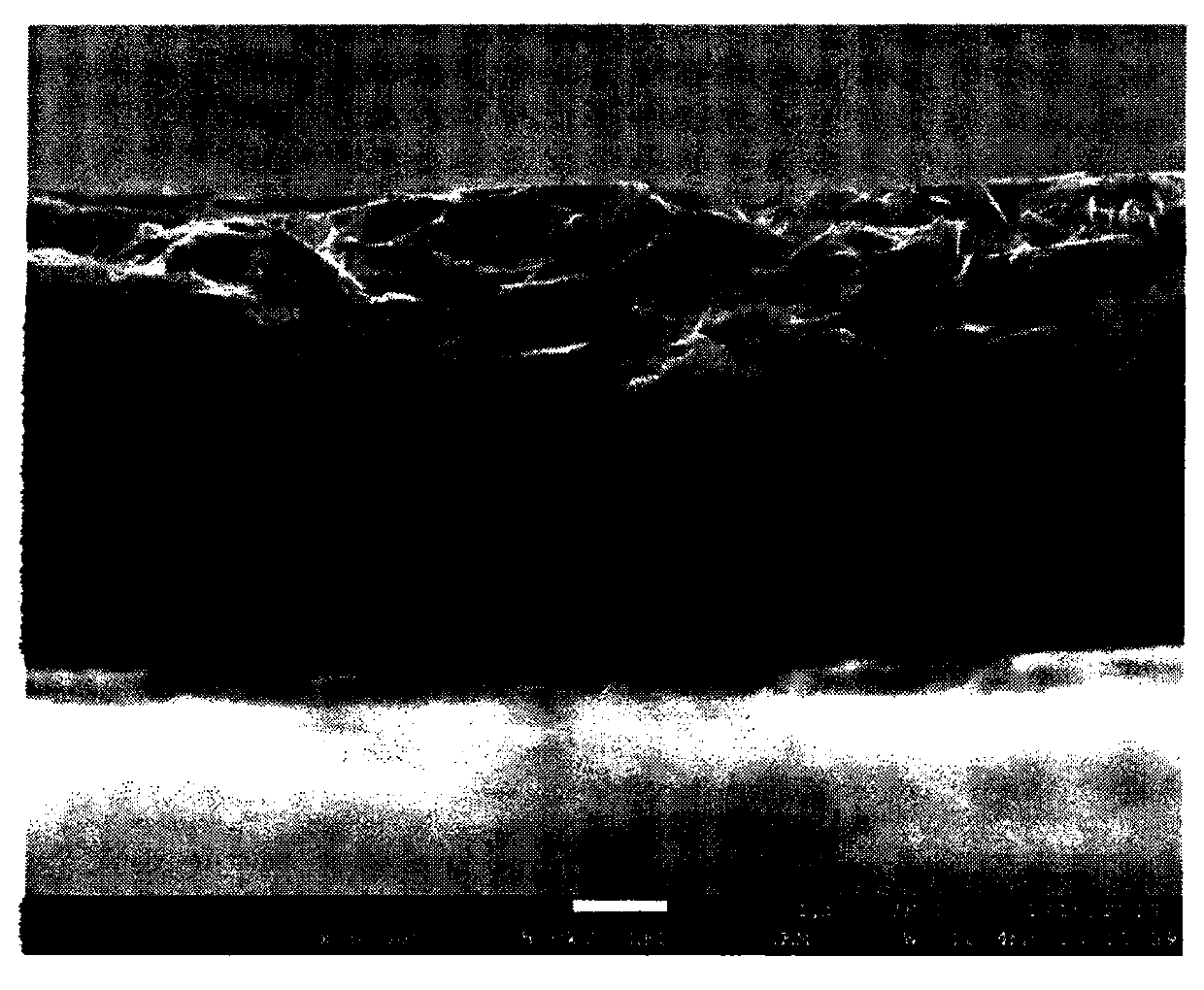

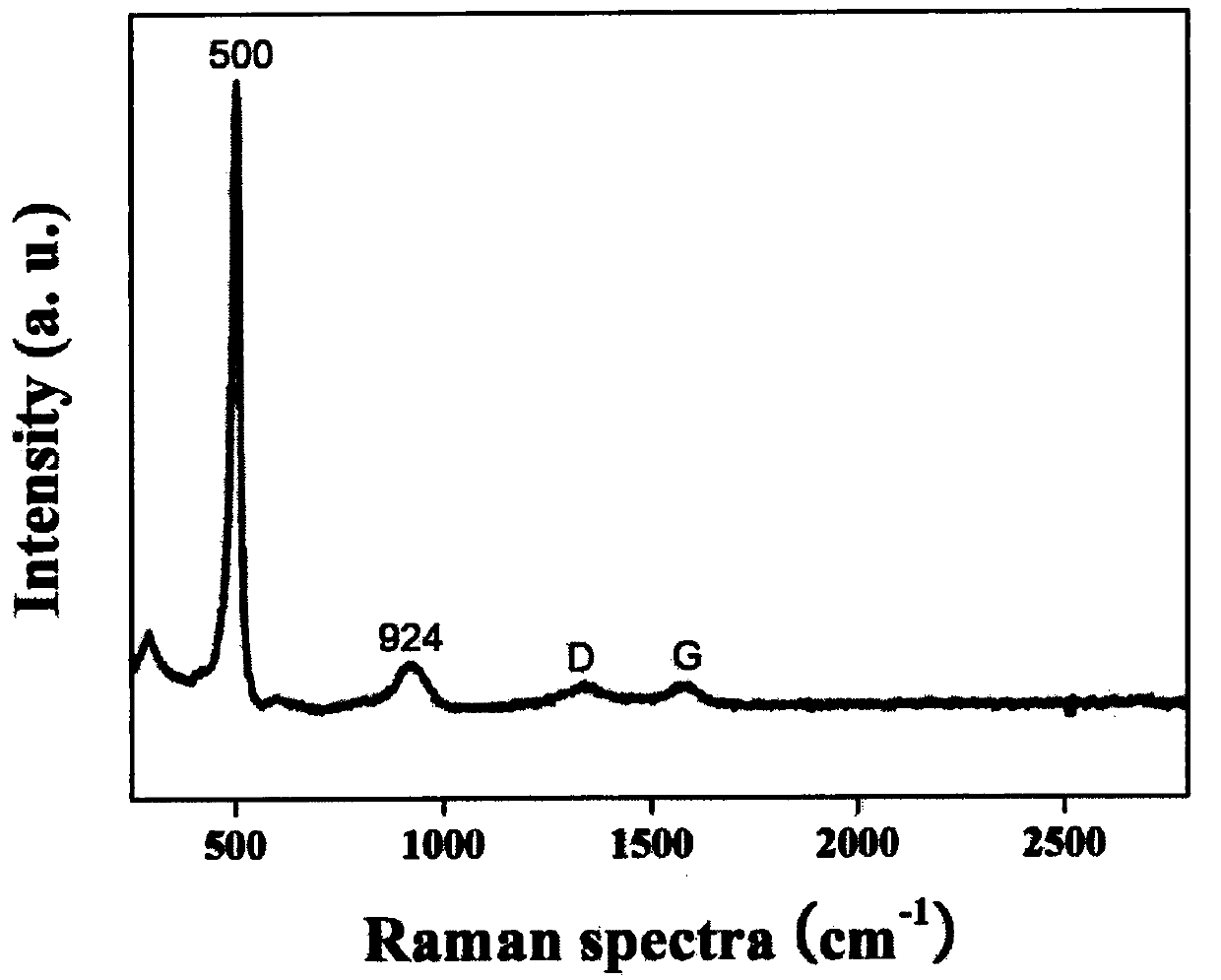

[0031] A graphene / silicon composite lithium-ion battery negative electrode, including copper foil and a five-layer structure arranged on the copper foil, such as figure 1 As shown, the five-layer structure includes 3 graphene layers and 2 layers of silicon / carbon nanotube layers, the graphene layer and silicon / carbon nanotube layers are arranged alternately, and the silicon / carbon nanotube layers contain silicon nanotubes Particles and carbon nanotubes, carbon nanotubes coated on silicon nanoparticles. The graphene layer can prevent silicon materials from agglomerating during the charging and discharging process, and carbon nanotubes can be coated on silicon nanoparticles to achieve the first level of coating, while improving the conductivity of silicon nanoparticles; the relationship between carbon nanotubes and graphene The inter-π-π stacking connection also makes the structure more compact and stable, which can effectively limit the volume expansion of silicon during chargi...

Embodiment 2

[0041] A graphene / silicon composite lithium-ion battery negative electrode, including copper foil and a five-layer structure arranged on the copper foil, such as figure 1 As shown, the five-layer structure includes 3 graphene layers and 2 layers of silicon / carbon nanotube layers, the graphene layer and silicon / carbon nanotube layers are arranged alternately, and the silicon / carbon nanotube layers contain silicon nanotubes Particles and carbon nanotubes, carbon nanotubes coated on silicon nanoparticles. The graphene layer can prevent silicon materials from agglomerating during the charging and discharging process, and carbon nanotubes can be coated on silicon nanoparticles to achieve the first level of coating, while improving the conductivity of silicon nanoparticles; the relationship between carbon nanotubes and graphene The inter-π-π stacking connection also makes the structure more compact and stable, which can effectively limit the volume expansion of silicon during chargi...

Embodiment 3

[0051] A graphene / silicon composite lithium-ion battery negative electrode, including copper foil and a five-layer structure arranged on the copper foil, such as figure 1 As shown, the five-layer structure includes 3 graphene layers and 2 layers of silicon / carbon nanotube layers, the graphene layer and silicon / carbon nanotube layers are arranged alternately, and the silicon / carbon nanotube layers contain silicon nanotubes Particles and carbon nanotubes, carbon nanotubes coated on silicon nanoparticles. The graphene layer can prevent silicon materials from agglomerating during the charging and discharging process, and carbon nanotubes can be coated on silicon nanoparticles to achieve the first level of coating, while improving the conductivity of silicon nanoparticles; the relationship between carbon nanotubes and graphene The inter-π-π stacking connection also makes the structure more compact and stable, which can effectively limit the volume expansion of silicon during chargi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com