Cation montmorillonite sludge dehydrant as well as preparation method and application thereof

A sludge dehydrating agent, montmorillonite-type technology, applied in the direction of dehydration/drying/concentration sludge treatment, oxidation treatment sludge, etc., can solve the limitation of Fenton reaction sludge dehydration, sludge weight gain and reduce sludge heat Value, impact on sludge resource utilization and other issues, to achieve good application value and promotion potential, good variety of properties, huge specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

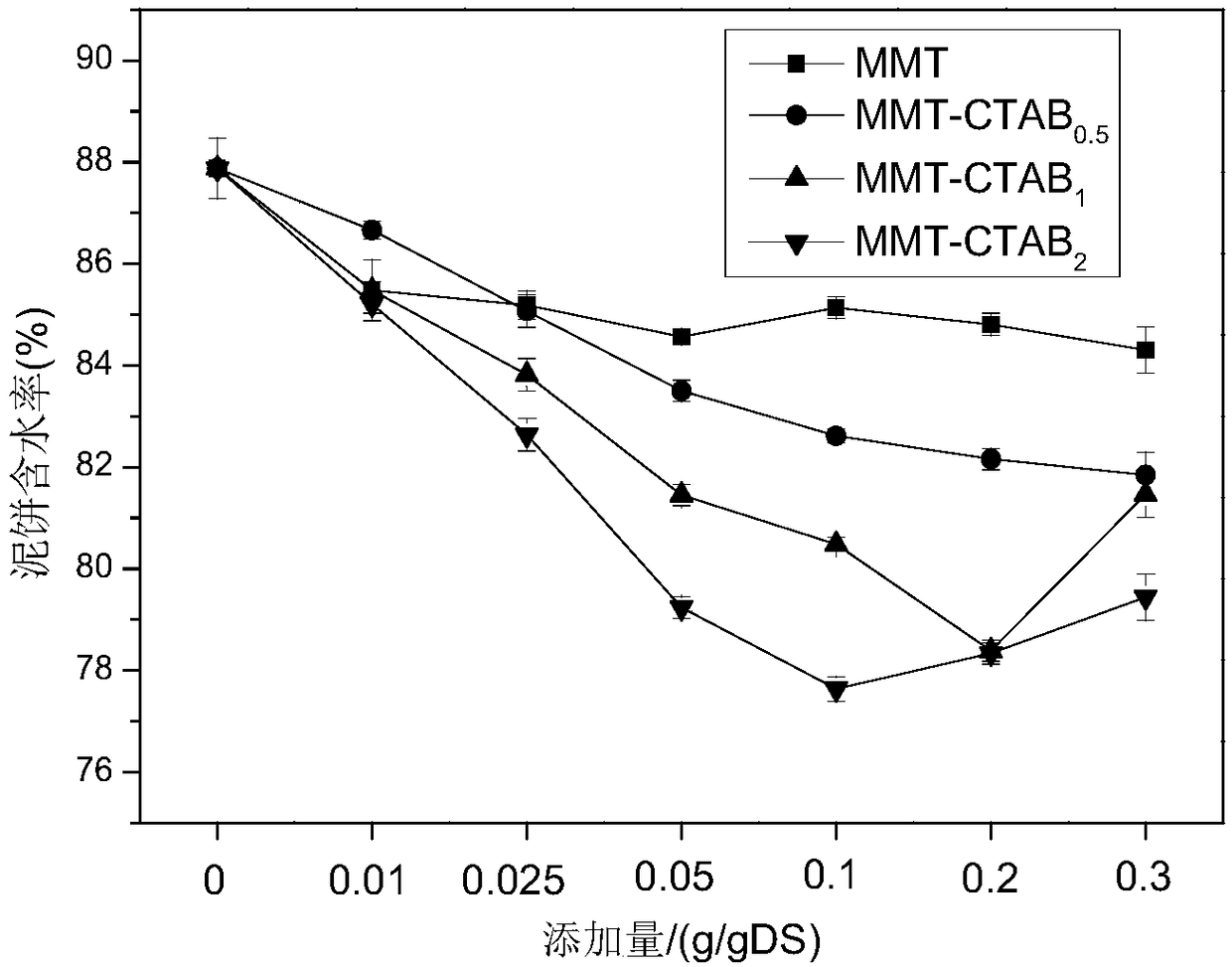

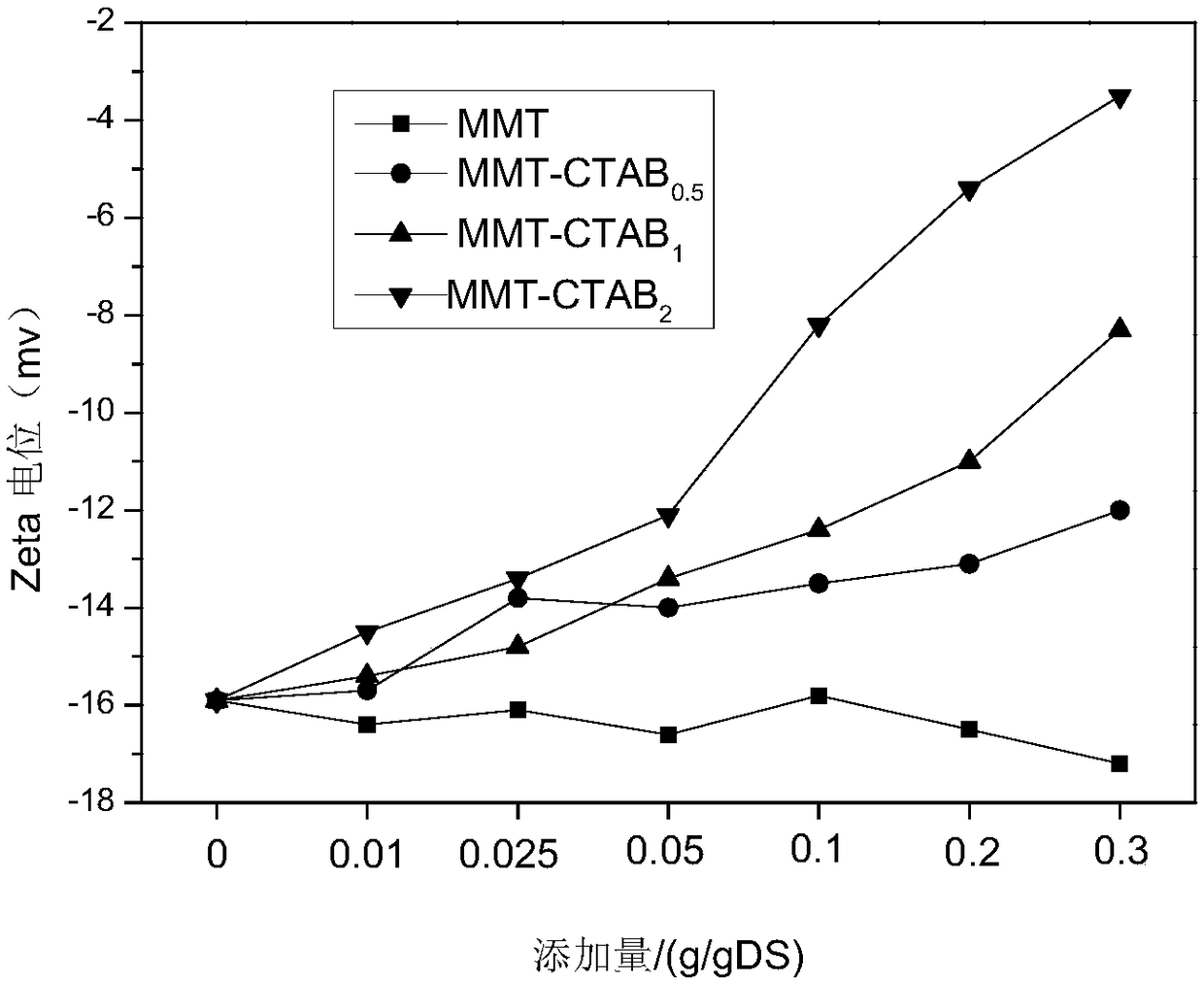

[0032] Embodiment 1: the preparation of dehydrating agent

[0033] (1) Mix 100 parts by weight of montmorillonite, 600 parts by weight of deionized water, 1.5 parts by weight of CTAB, and 100 parts by weight of absolute ethanol at room temperature, stir with a constant temperature magnetic stirrer at 60°C for 24 hours, and then cool to room temperature.

[0034] (2) The mixed solution is placed in an 8000rpm / min centrifuge for 5 minutes, and the centrifuged solid material is repeatedly washed with deionized water until no bromide ions exist in the eluate (use AgNO 3 Titrate the eluate until no white precipitate is formed).

[0035] (3) The remaining solid matter was dried in a vacuum drying oven at 110°C for 12 hours. After the material was cooled, it was ground through a 200-mesh sieve, and the powder material was saved for later use. The prepared material was named MMT-CTAB 0.5 .

Embodiment 2

[0036] Embodiment 2: the preparation of dehydrating agent

[0037] (1) Mix 100 parts by weight of montmorillonite, 600 parts by weight of deionized water, 3 parts by weight of CTAB, and 100 parts by weight of absolute ethanol at room temperature, stir with a constant temperature magnetic stirrer at 60°C for 24 hours, and then cool to room temperature.

[0038] (2) The mixed solution is placed in an 8000rpm / min centrifuge for 5 minutes, and the centrifuged solid material is repeatedly washed with deionized water until no bromide ions exist in the eluate (use AgNO 3 Titrate the eluate until no white precipitate is formed).

[0039] (3) The remaining solid matter was dried in a vacuum drying oven at 110°C for 12 hours. After the material was cooled, it was ground through a 200-mesh sieve, and the powder material was saved for later use. The prepared material was named MMT-CTAB 1 .

Embodiment 3

[0040] Embodiment 3: the preparation of dehydrating agent

[0041] (1) Mix 100 parts by weight of montmorillonite, 600 parts by weight of deionized water, 6 parts by weight of CTAB, and 100 parts by weight of absolute ethanol at room temperature, stir with a constant temperature magnetic stirrer at 60°C for 24 hours, and then cool to room temperature.

[0042] (2) The mixed solution is placed in an 8000rpm / min centrifuge for 5 minutes, and the centrifuged solid material is repeatedly washed with deionized water until no bromide ions exist in the eluate (use AgNO 3 Titrate the eluate until no white precipitate is formed).

[0043] (3) The remaining solid matter was dried in a vacuum drying oven at 110°C for 12 hours. After the material was cooled, it was ground through a 200-mesh sieve, and the powder material was saved for later use. The prepared material was named MMT-CTAB 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com