Catalyst for synthesizing low-carbon alcohol and preparation method thereof

A catalyst and low-carbon alcohol technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve problems such as difficulty in stability, and achieve the effects of stable performance, uniform surface distribution, and high heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

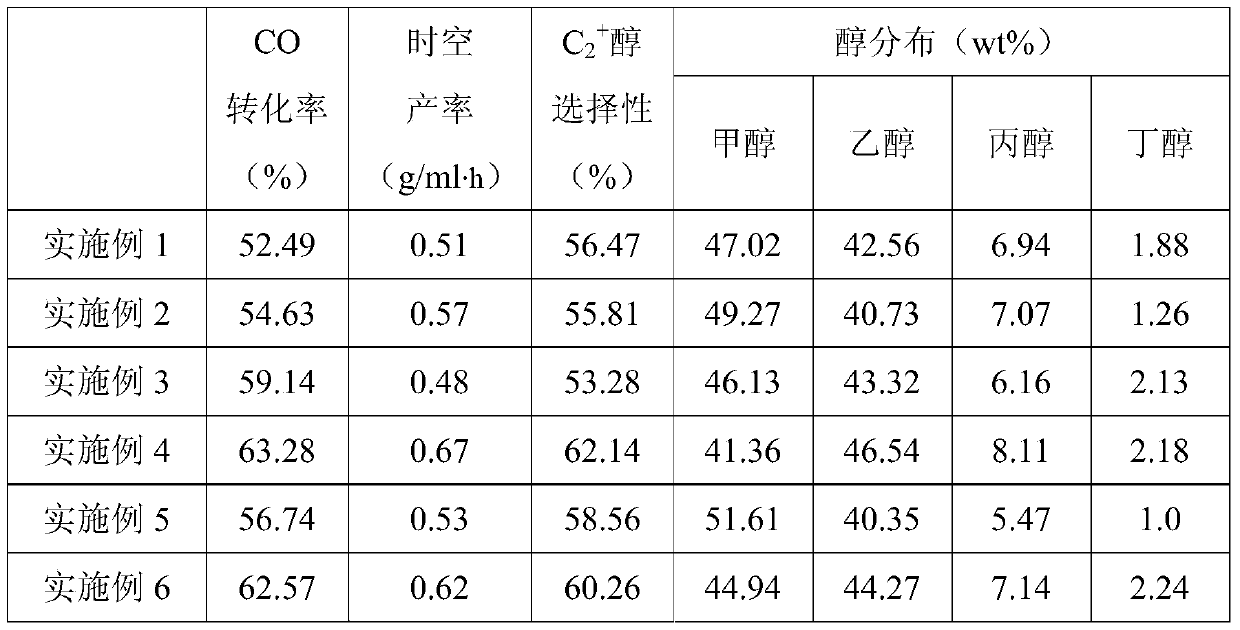

Examples

Embodiment 1

[0024] (catalyst preparation)

[0025] Heat 3 L of deionized water to 60 °C, press Cu 1 Fe 0.25 Zn 0.25 Molecular formula, weigh 69g ferric nitrate, 214.2g copper nitrate, 85g zinc nitrate, dissolve in deionized water to form a mixed solution; keep the temperature of the mixed solution at 60°C, stir while heating, add 328.9g citric acid and 15g of polyethylene glycol; add 547.1g of inert alumina powder to the above solution, and then gradually add ammonia water to adjust the pH value of the system to 7, and heat and age at 60°C to obtain a gel after slow evaporation; The glue is dried at 120°C, calcined at 350°C, and crushed to below 100 mesh to obtain an active component coated with inert alumina, wherein the inert alumina accounts for 80% of the weight of the active component; Mix the active component with 4 times the weight of alumina balls, add SiO 2 The silica sol with a mass percentage of 20% was coated, and then dried at 100° C. for 5 hours to obtain a catalyst.

...

Embodiment 2

[0029] (catalyst preparation)

[0030] Heat 3 L of deionized water to 60 °C, press Cu 1 Fe 0.4 Zn 0.25 Molecular formula, weigh 110.5g ferric nitrate, 214.2g copper nitrate, 85g zinc nitrate, dissolve in deionized water to form a mixed solution; keep the temperature of the mixed solution at 60°C, stir while heating, add 362g citric acid and 15g of polyethylene glycol; add 1354.5g of inert alumina powder to the above solution, and then gradually add ammonia water to adjust the pH value of the system to 7, and heat and age at 60°C to obtain a gel after slow evaporation; The glue is dried at 120°C, roasted at 350°C, and crushed to below 100 mesh to obtain an active component coated with inert alumina, wherein the inert alumina accounts for 90% of the weight of the active component; Mix the active component with 4 times the weight of alumina balls, add SiO 2 The silica sol with a mass percentage of 20% was coated, and then dried at 100° C. for 5 hours to obtain a catalyst.

...

Embodiment 3

[0034] (catalyst preparation)

[0035] Heat 3 L of deionized water to 60 °C, press Cu 1 Fe 0.25 Zn 0.5 Molecular formula, weigh 69g ferric nitrate, 214.2g copper nitrate, 169.8g zinc nitrate, dissolve in deionized water to form a mixed solution; keep the temperature of the mixed solution at 60°C, stir while heating, add 381.8g citric acid and 15g of polyethylene glycol; add 1432.6g of inert alumina powder to the above solution, and then gradually add ammonia water to adjust the pH value of the system to 7, and heat and age at 60°C to obtain a gel after slow evaporation; The gel is dried at 120°C, calcined at 350°C, and crushed to below 100 mesh to obtain an active component coated with inert alumina, in which the inert alumina accounts for 90% of the weight of the active component; In the machine, the active component is mixed with 4 times the weight of alumina balls, and SiO is added 2 The silica sol with a mass percentage of 20% was coated, and then dried at 100° C. for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com