Preparation method of bacterial cellulose

A technology of bacterial cellulose and cellulose, which is applied in the field of industrial biology, can solve problems such as immaturity, and achieve the effects of reducing fermentation costs, simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: 7L NBS tank fermentation

[0031] 1) Shake flask strain preparation: scrape a ring of slanted seeds and connect them to the sterilized seed medium (glucose 20, yeast extract 2, peptone 2, CaCO3 0.5, unit g / L, pH value natural), 28°C, 100r / min cultured for 16 hours and then expanded with culture;

[0032] 2) Preparation of molasses: pre-dilute the original sugarcane molasses by 2 times, adjust the pH value to 2.0 with sulfuric acid, hydrolyze at 90° C. for 30 minutes, centrifuge or filter the supernatant after standing overnight and then dilute 10 times, the pH value is 6.0;

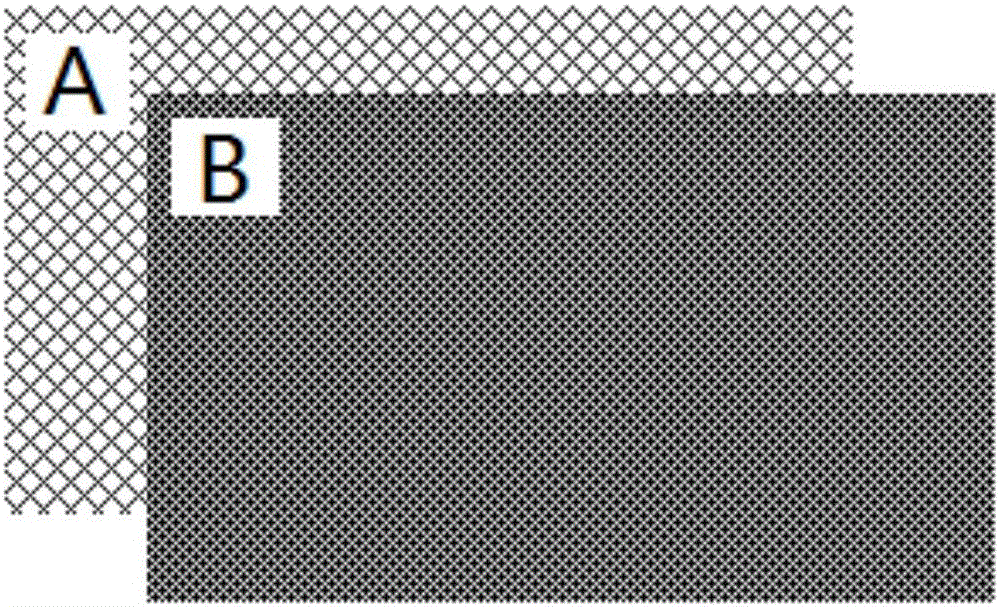

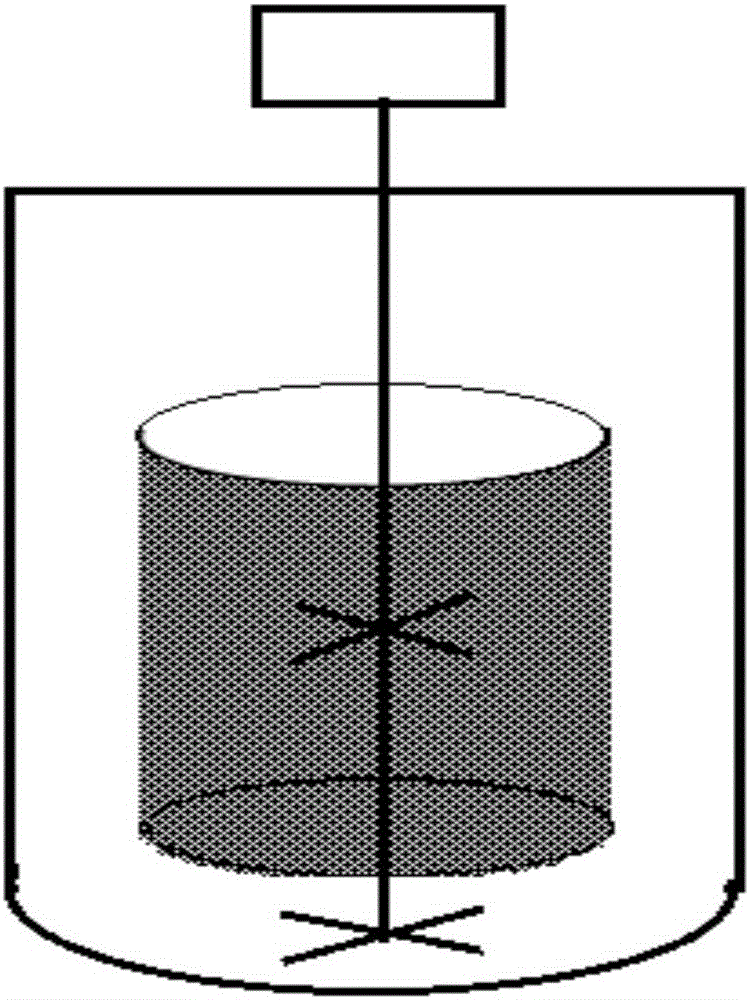

[0033] 3) Fermentation: inoculate the seeds in a certain amount of sugarcane molasses medium (molasses 25, glycerol 0.5, corn steep liquor 10g / L, ammonium sulfate 0.5, citric acid 1.0, disodium hydrogen phosphate 2.0, magnesium sulfate 0.2, Unit g / L) fermenter was stirred and fermented for 8 days; wherein, the stirred tank was a bioreactor equipped with gauze, and the gauze was hung ...

Embodiment 2

[0035] Example 2: 50 liters of stirred tank fermentation

[0036] 1) Strain preparation: Scrape a ring of slanted seeds and connect them to the sterilized seed medium (glucose 40, yeast extract 5, peptone 5, CaCO3 1, unit g / L, pH value natural), 32°C, 150r / After 24 hours of culture, move to the NBS tank in Example 1 for expansion, the liquid volume is 3L, the culture medium is similar to the shake flask, the rotation speed is 100r / min, the ventilation rate is 1.0vvm, and the temperature is 32°C and the culture is stirred for 20 hours;

[0037] 2) Preparation of molasses: pre-dilute the beet molasses by 5 times, adjust the pH value to 2.5 with sulfuric acid, hydrolyze for 20 minutes at 100° C., centrifuge or filter the supernatant after standing overnight and then dilute it by 2 times, and the pH value is 5.5;

[0038]3) Fermentation: Inoculate the seeds in 30L molasses medium (molasses 50, glycerin 0.2, corn steep liquor 20g / L, ammonium sulfate 1.5, citric acid 1.5, disodium ...

Embodiment 3

[0040] Embodiment 3: 2 tons of stirred tank fermentation

[0041] 1) Strain preparation: Scrape a ring of slanted seeds and connect to 100mL seed medium (glucose 25, yeast extract 2.5, peptone 2.5, CaCO 3 3, unit g / L, pH value natural) 500mL Erlenmeyer flask, cultured at 30°C, 150r / min for 20 hours, then cultured in a 5L Erlenmeyer flask with 1L medium for 20 hours under the same conditions. Move to a 200L seed tank with 100L medium for expansion. The medium is similar to that of a shaker flask, and the rotation speed is 90r / min, the ventilation rate is 1.5vvm, and the temperature is 30°C and stirred for 24 hours;

[0042] 2) Preparation of molasses: pre-dilute sugarcane molasses 4 times, adjust the pH value to 3.0 with sulfuric acid, hydrolyze at 120° C. for 15 minutes, centrifuge or filter the supernatant after standing overnight and then dilute 2.5 times, the pH value is 4.8;

[0043] 3) Fermentation: move the seeds to inoculate in 1200L molasses medium (molasses 50, glyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com