Method for preparing taste-active peptides and delicious amino acids by using aspergillus oryzae fermented peanut meal and application thereof

A technology for fermenting peanut meal and Aspergillus oryzae, which is applied in the field of microbial fermentation, can solve the problems of high cost, increased peptidase price and debittering cost, and low enzymatic hydrolysis peptide production rate, and achieves low cost, rich enzyme system, and fast growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) UV mutagenesis of Aspergillus oryzae AS3.95 spores

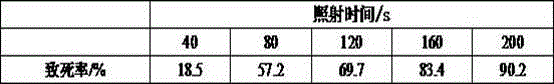

[0033] Take 2 mL of Aspergillus oryzae AS3.95 suspension in a sterile petri dish with a diameter of 12 cm, the thickness of the liquid is within 1 mm, and irradiate it at a distance of 30 cm from a 30 w ultraviolet lamp while shaking the petri dish. After dilution, it was spread on casein plate medium and cultured at 37°C. When the irradiation time was 80s, the lethality rate of Aspergillus oryzae spores was about 57%. When the irradiation time was 120s, the lethality rate of Aspergillus oryzae spores was about 70% (Table 1).

[0034] Table 1 Effect of UV irradiation time on the lethality of Aspergillus oryzae

[0035]

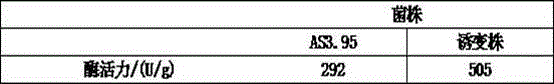

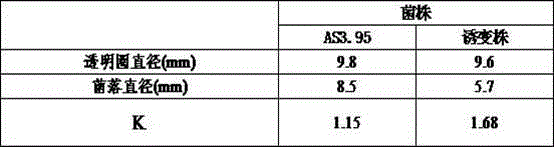

[0036] (2) Initial screening of Aspergillus oryzae mutant strains

[0037] The Aspergillus oryzae mutant strain was cultured on a casein plate medium at 37°C for 48 h, the diameter of the colony and the diameter of the hydrolysis transparent circle were measured, and the ratio K of the diamet...

Embodiment 2

[0056] (1) UV mutagenesis of Aspergillus oryzae AS3.95 spores

[0057]Take 2 mL of Aspergillus oryzae AS3.95 suspension in a sterile petri dish with a diameter of 12 cm, the thickness of the liquid is within 1 mm, and irradiate it at a distance of 30 cm from a 30 w ultraviolet lamp while shaking the petri dish. Spread on casein plate medium after dilution and culture at 37°C. When the irradiation time was 80s, the lethality rate of Aspergillus oryzae spores was about 57%. When the irradiation time was 120s, the lethality rate of Aspergillus oryzae spores was about 70% (Table 7).

[0058] Table 7 The influence of ultraviolet irradiation time on the lethality of Aspergillus oryzae

[0059]

[0060] (2) Initial screening of Aspergillus oryzae mutant strains

[0061] The Aspergillus oryzae mutant strain was cultured on a casein plate medium at 37°C for 48 h, the diameter of the colony and the diameter of the hydrolysis transparent circle were measured, and the ratio K of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com